- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Supercapacitor Assembly Equipment

- Dry Electrode Assembly Equipment

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Cylinder Cell Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- Customized Electrode

1200°C Tube Furnace with Internal Travel Mechanism For HPCVD

Model Number:

TMAX-1200X-S-HPCVDCompliance:

CE compliantWarranty:

Two years limited warranty with lifetime technical supportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 days

1200°C Tube Furnace with Internal Travel Mechanism For HPCVD

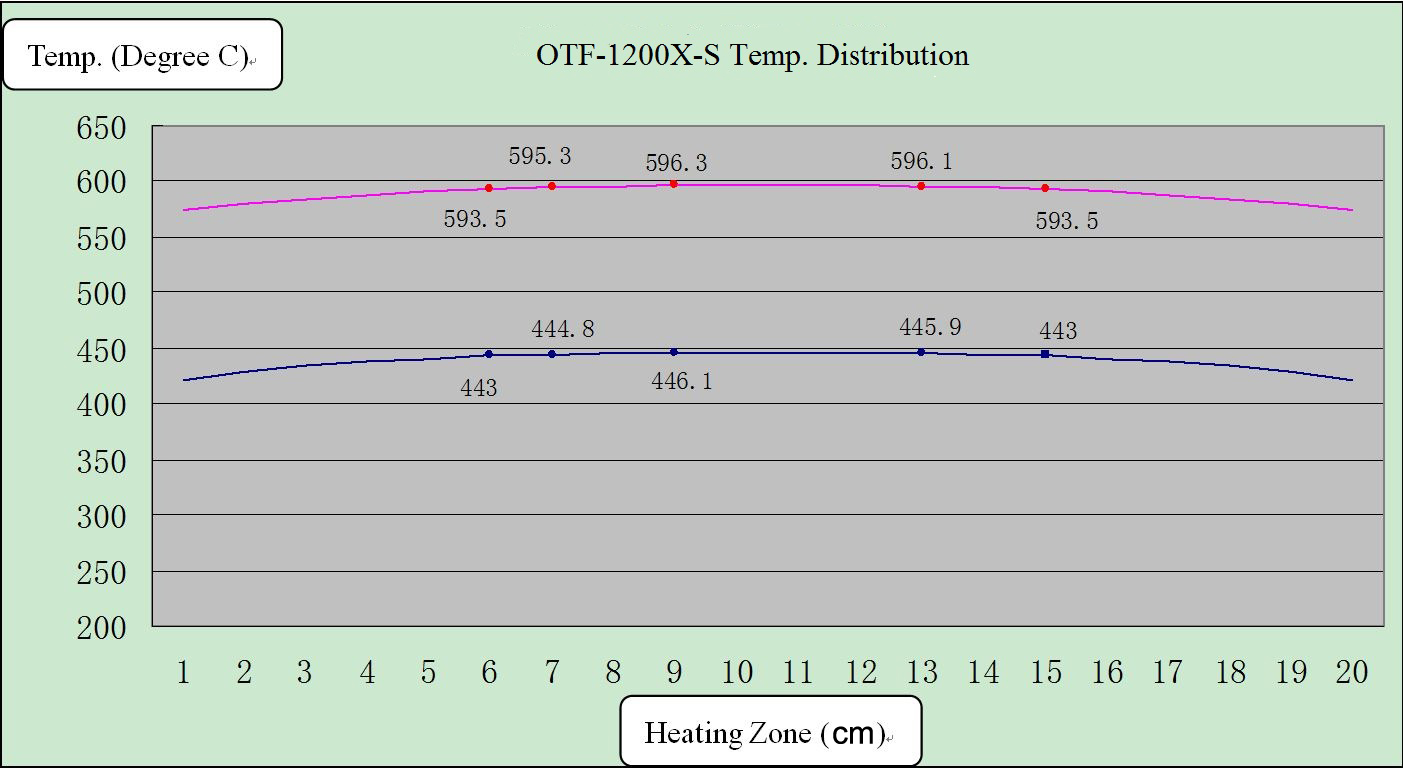

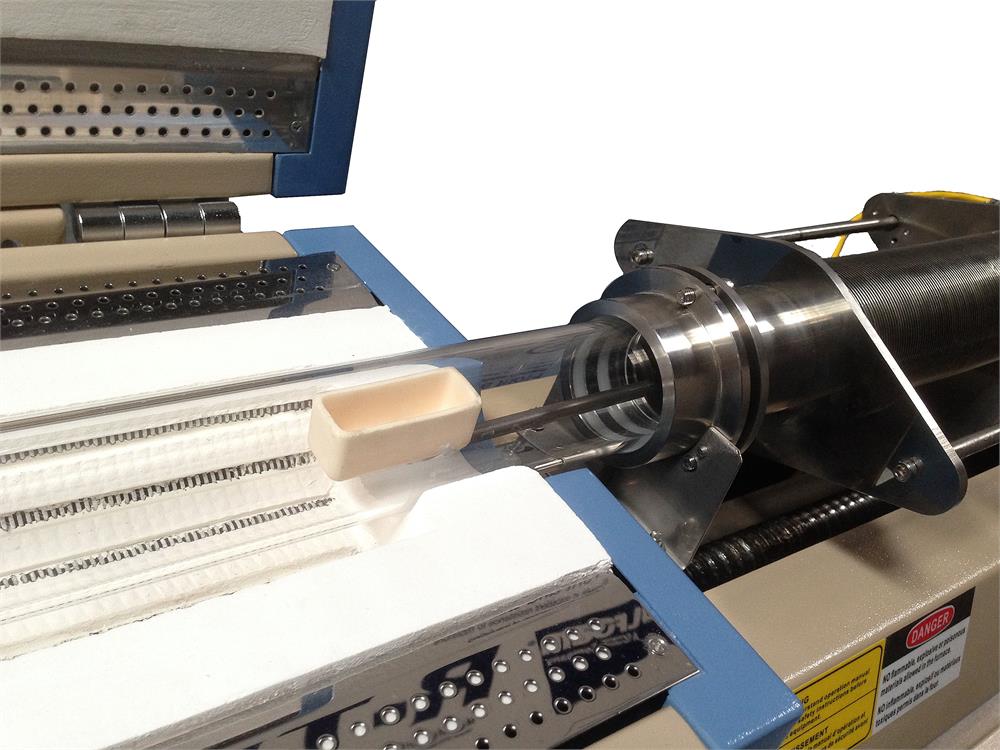

TMAX-1200X-S-HPCVD is a compact 2" split tube furnace with internal sample traveling system inside the processing tube. This allows the position & temperature control of the sample stage or crucible via touch screen digital controller. It is designed for multi-functional rapid thermal processing, such as hybrid physical-chemical deposition(HPCVD), rapid thermal evaporation (RTE), and as well Horizontal Bridgman Crystal Growth ( HDC) under various atmosphere for new generation crystal research.

SPECIFICATIONS:

|

Split Tube Furnace |

|

||

|

Temperature Control |

|

||

|

Vacuum Sealing

|

|

||

|

Internal Traveling

Mechanism

& |

|

||

|

Max. Heating & Cooling Rate |

The max heating and cooling rate can be achieved by moving sample into pre-heated hot zone and move the sample out from hot zone. The typical ramp/cool rate is listed in below:

|

||

|

|

|

||

|

Dimensions |

|

||

|

Warranty |

Two years limited warranty with lifetime support (Consumable parts such as tubes and o-rings are not covered by the warranty) |

||

|

Laptop, software & WiFi Control(Optional) |

|

||

|

|

|

||

|

|||

|

Application Notes |

This multi-functional furnace is suitable for the applications in below:

|

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat 13506084915

Wechat 13506084915