- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Supercapacitor Assembly Equipment

- Dry Electrode Assembly Equipment

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Cylinder Cell Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- Customized Electrode

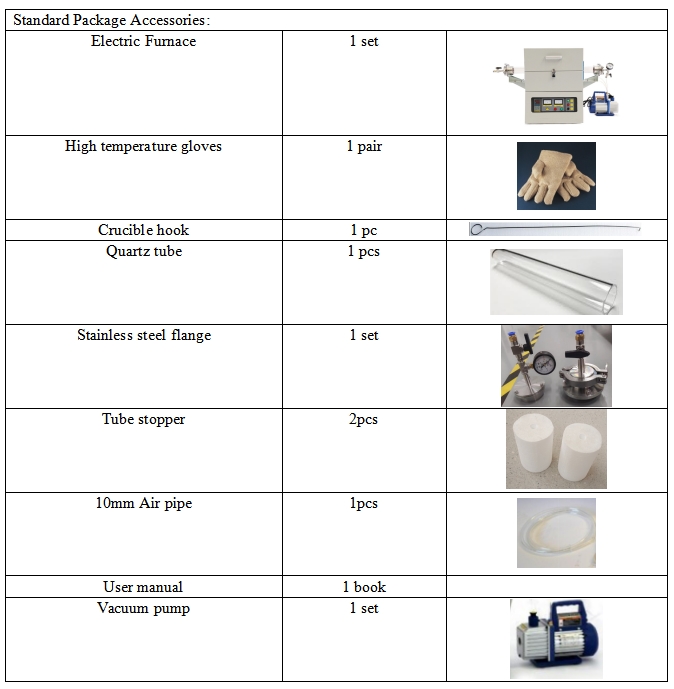

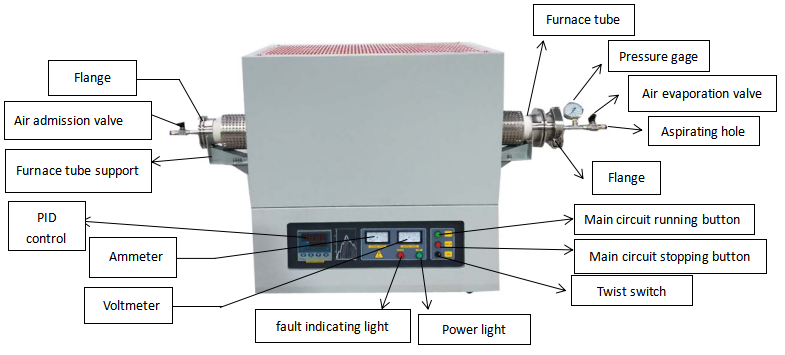

Lab 1200℃ Single-Zone Split Tube Furnace

Model Number:

TMAX-SK2Compliance:

CE certificateWarranty:

One year limited warranty with lifetime technical supportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 days

Lab 1200℃ Single-Zone Split Tube Furnace

|

Specification |

Detail |

|

Max. Temperature |

1200°C |

|

Working Temperature Range |

0-1100°C |

|

Tube Diameter |

40/60/80/100 mm upon request |

|

Heating Zone Length |

205/350/440 mm upon request Note: A heating section of 205 mm corresponds to a tube length of 800 mm, a heating section of 350 mm corresponds to a tube length of 1000 mm, and a heating section of 440 mm corresponds to a tube length of 1200 mm (Special attention: For a 1200-degree tube furnace, a 440 mm heating section corresponds to a tube length of 1000 mm). |

|

Power supply and Power |

40*205=220V/2kw 60*205=220V/2kw 80*205=220V/2xw 100*205=220V/2kw 40*350=220V/3kw 60*350=220V/3kw 80*350=220V/3kw 100*350=220V/3kw 40*440=220V/4kw 60*440=220V/4kw 80*440=220V/4kw 100*440=220V/4kw |

|

Tube Material |

Quartz tube |

|

Heating Rate |

0~20°C/Min |

|

Voltage |

220V, single phase 50/60Hz |

|

Max. Vacuum |

-0.1Mpa |

|

Heating Element |

Resistance wire |

|

Thermocouple |

K type |

|

Temperature Accuracy |

±1℃ |

|

Specification |

Detail |

|

Max. Temperature |

1200°C |

|

Working Temperature Range |

0-1100°C |

|

Inlet gas/Atmosphere |

It can be filled with various protective or destructive gases,Inert gases, mixed gases, nitrogen, oxygen, etc |

|

Gas control |

The air inlet can be set up 1 or more air intakes, each air inlet is provided with a needle valve, connected with a vacuum gauge. The air outlet is connected with one air outlet, and all holes are equipped with needle valves. Equipped with a vacuum pump. |

|

Appearance design |

The electric furnace adopts humanized design, beautiful and easy to operate, and the outer layer of paint is sprayed with high temperature baking technology. High temperature resistance, oxidation resistance, acid and alkali resistance. Color selection is aging resistant tone, will not cause the appearance color fade due to a long time of use. |

|

Furnace Chamber material |

Adopt the most advanced light alumina ceramic fiber in the world, with excellent thermal insulation effect, light weight, high temperature resistance, cold and heat resistance, no crack, no crystallization, no slag, do not worry about pollution of the fired products. The energy saving effect is 60-80% of the old electric furnace. |

|

Furnace chamber design |

Furnace adopts the stepped assembly structure, integrating the mechanical law, effectively ensure the furnace in the heating process of uniform force, ensure that the heat is not easy to disperse, prolong the service life of the furnace. |

|

Furnace shell structure |

Electric furnace shell adopts double layer forced air cooling structure, so that the electric furnace works at the highest temperature and the external temperature of the shell is close to room temperature, so as to avoid accidental injury. |

|

Sealing way |

Adopt 304 stainless steel flange, with easy loading and unloading, oxidation resistance, acid and alkali resistance, double seal, ensure the sealing |

|

Sealing way |

Adopt 304 stainless steel flange, with easy loading and unloading, oxidation resistance, acid and alkali resistance, double seal, ensure the sealing Two stainless steel vacuum flanges (mechanical pressure gauges installed on top) In order to obtain higher vacuum faster, stainless steel bellows are recommended. In order to obtain a higher air outlet rate a higher vacuum degree is obtained, our standard is KF Flange. |

|

Pressure gauge |

Standard: mechanical vacuum pressure,measuring range: 0-0. 1Mpa,The maximum pressure shall not exceed 0.02mpa |

|

Temperature control security |

The electric furnace adopts integrated circuit, module control, double circuit protection (partial temperature protection, ultra-high temperature protection, coupling protection, overcurrent protection, overpressure protection and other protection functions) to make the electric furnace work stable and reliable, safe. |

|

Warranty |

One year limited warranty with lifetime support, excluding heating element,cooling fans,thermocouple and ceramic tube damaged by user. Attention: Any damages caused by the use of corrosive and acidic gases, and any damage from wrong operate and use are not under the coverage of One Year Limited Warranty. |

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat 13506084915

Wechat 13506084915