- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Supercapacitor Assembly Equipment

- Dry Electrode Assembly Equipment

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Cylinder Cell Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- Customized Electrode

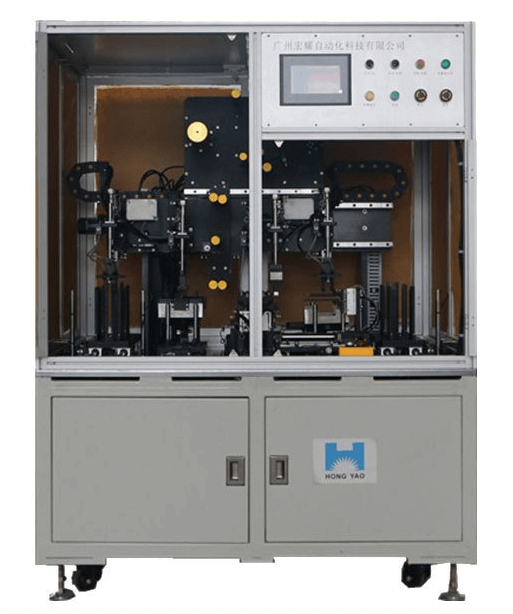

Lab Semi-auto Stacker Prismatic Cell Stacking Machine For Battery Assemble

Model Number:

TMAX-PCSM200Compliance:

CE certificateWarranty:

2 year limited warranty with lifetime supportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 days

1、 Functional Overview

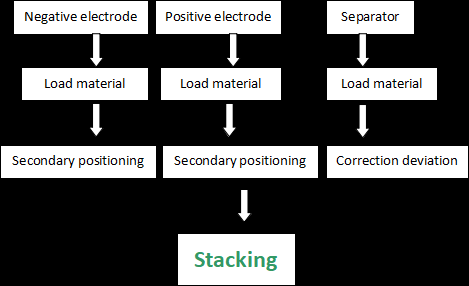

The equipment is mainly used to assemble the positive electrode, negative electrode and separator of lithium-ion battery cells with Z-shaped stacking, making them into cells.

The left and right manipulator mechanisms of the equipment pick up the electrode plates in the positive and negative material slots, and after precise positioning by the secondary positioning workbench, alternate material placement is carried out on the stacking platform; The stacking platform moves left and right in conjunction with the two manipulators, and forms a Z-shaped isolation film to separate the positive and negative electrode plates; The device circulates in this way to achieve the stacking assembly of the electrode group.

2、 Basic parameters

1. Size: 1850mm (L) × 1350mm (D) × 1850mm (H); Subject to completion of design

2. Power supply: 220V 50HZ

3. Air source: 0.5MPa

4. No corrosive gases, liquids, or explosive gases

5. Color: Supplier's standard color sample (International Warm Gray 1C)

3、 Technical parameters

1. Applicable specifications: length L130-260, width W 80-200mm, thickness H 0-20mm;

battery tab length Q ≤ 20m

2. Device speed: 1.3-1.5s/pcs;

3. Alignment accuracy of electrode and separator: center deviation ± 0.3mm;

4. Incoming material requirements: The electrode coating must be uniform, with a thickness error of less than 0.005mm and no wrinkling or bonding phenomenon; The error in length and width is less than ± 0.2 mm, and the wavy edge is less than 1mm (without affecting the positioning of the electrode); The battery tab is flat, without any bending or folding; The separator needs to be rolled evenly, with a width error of less than 0.1mm and a tower shape error of less than 0.2mm; The tape should be rolled evenly without obvious tower shaped, wrinkled, or warped phenomena;

5. The active unwinding control of the separator ensures that the tension is appropriate during the stacking process, ensuring that the elongation and deformation of the separator are small;

6. separator deviation correction ensures the uniformity of separator unwinding and alignment accuracy of ± 0.2mm.

7. Defect identification: Identify missing pieces.

8. 95% failure rate (caused solely by the machine), 98% pass rate (caused solely by the machine)

9. It is easy to change the model and can be employed with simple training

4、 Process performance

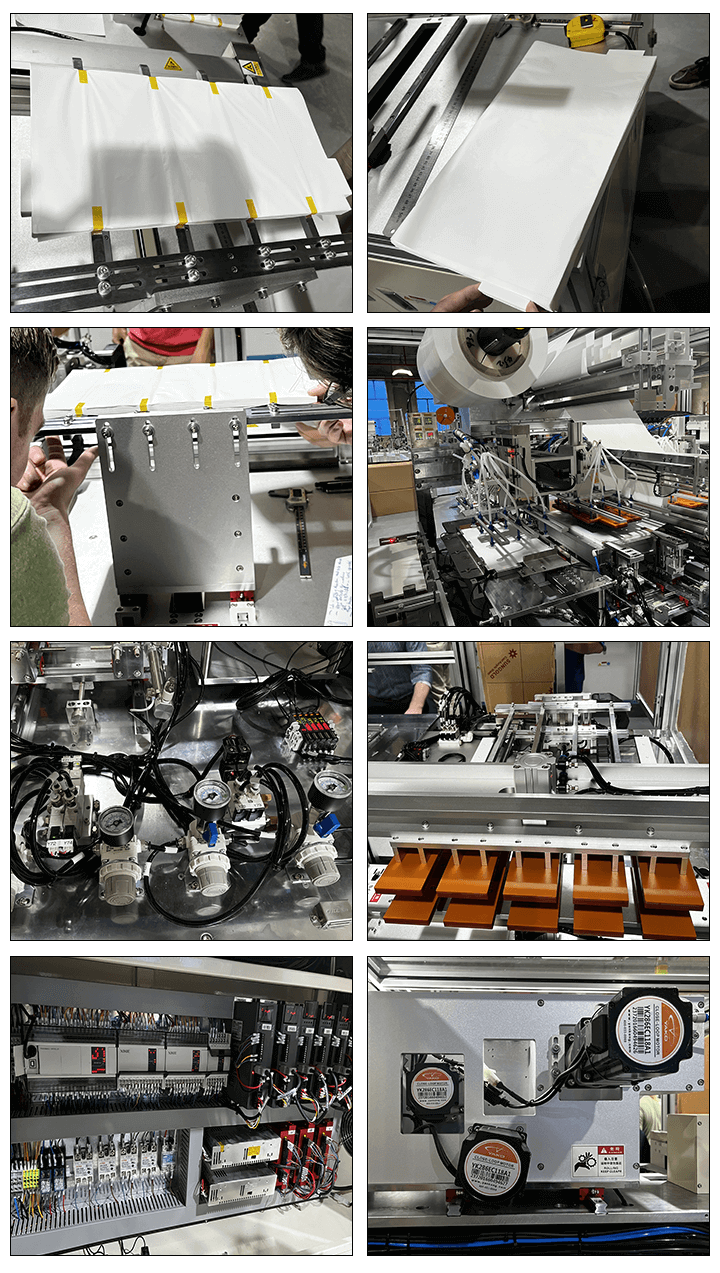

1. Both positive and negative electrode plates are equipped with material slots; Real time floating structure of polar plates in the working material trough;

2. Establish a secondary positioning mechanism for the positive and negative electrode plates to accurately locate the electrode plates;

3. The chip taking mechanical arm adopts a high-speed linear servo module group, which ensures stable and reliable vacuum feeding and discharging. It switches workstations between the material trough, secondary positioning platform, and stacking platform, and the positive and negative chip taking mechanical arms alternate feeding and discharging;

4. The separator unwinding mechanism adopts precise servo semi closed loop control, and the working tension is continuously adjustable; Establish a correction mechanism;

5. The stacking table mechanism is equipped with a precise guiding mechanism to enable the stacking table to rise and fall in real-time according to the thickness of the stacking, in order to adapt to different thicknesses of cells; Adopting a high-speed linear servo module group to drive and achieve high-speed, accurate, and stable operation between the positive and negative electrode plates, the electrode plates and the isolation film are folded in a Z-shape, and the cylinder drives the pressure claw to perform X-Y bidirectional composite motion, compressing and positioning the electrode plates and separator, achieving the Z-shaped stacking assembly process of the positive and negative electrode plates and the isolation film of the lithium battery cell, forming the battery cell;

6. The electrical control system is composed of a PLC program controller as the core, which uses set time, pressure, and position sensors as control signals to drive the motor, directional valve, cylinder, and other executing components to work, and automatically convert to complete the workflow;

7. Conduct human-machine dialogue through the human-machine interface, set up the operation of the entire machine, and display and provide feedback on various machine information.

5、 Main component configuration

A. Mechanical part

1) Stacking table mechanism:

l Adopting electromagnetic valves and pressure regulating valves to control the cylinder, and setting a high-precision guiding mechanism to enable the stacking table to rise and fall in real-time according to the thickness of the stacking, in order to adapt to different thicknesses of cells;

l Adopting a high-speed linear servo module group drive, it enables high-speed, accurate, and stable reciprocating motion between the positive and negative electrode chip taking manipulator;

l The cylinder drives the gripper to perform X-Y bidirectional composite motion, compressing and positioning the electrode and separator, achieving a Z-shaped stacking assembly process for the positive and negative plates of the lithium battery cell and the isolation film, forming the cell

l Install positive and negative electrode pressure claws on the stacking platform to alternately press the positive and negative electrodes to prevent cross contamination of the battery.

2) Mechanical arm:

l Adopting a high-speed linear servo module group, it operates accurately, quickly, and stably between the material trough, secondary positioning platform, and stacking platform;

l Stable and reliable vacuum feeding and discharging are adopted, and high-precision vacuum gauges are used to detect vacuum degree. Adjustable according to actual needs, with automatic confirmation and memory functions for feeding or not;

l The vacuum pipeline is equipped with a vacuum filter to prevent dust from entering the electrical components, making the vacuum meter, vacuum generator, and other components durable and durable;

3) separator unwinding mechanism:

l Adopting a DC brushless motor and angle sensor closed-loop control, precise pressure regulating valve controls the cylinder to drive the swing roller, keeping the working tension constant and ensuring uniform and consistent battery stacking tightness;

l The deviation correction system is paired with a high-speed linear module group to ensure that the positive and negative plates and separator are neat and consistent during stacking and winding.

4) Station electrode slot:

l Both positive and negative electrode plates are equipped with material slots;

l Automatic detection when there is no material in the material tank;

l Alarm prompt when there is no material in the material tank;

l Real time floating structure of polar plates in the working material slot.

5) Secondary positioning mechanism:

l Accurately locate the individual positive and negative electrodes to ensure the accuracy of the stacking;

l Equipped with defect detection function.

B. Electrical part

• PLC: Omron CP1H-X40DT

• PLC expansion module: Omron CP1W-40EDT/20EDT

• Touch screen: Kunlun on state TPC7062KD

• Electromagnetic valve: EMC

• Air cylinder: AIRTAC

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat 13506084915

Wechat 13506084915