- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Supercapacitor Assembly Equipment

- Dry Electrode Assembly Equipment

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Cylinder Cell Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- Customized Electrode

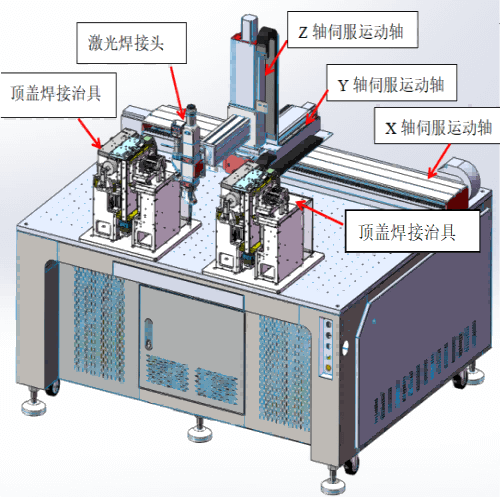

Laboratory Laser Welder For Battery Prismatic Cell Top Case Welding

Model Number:

TMAX-HJ-4000Compliance:

CE certificateWarranty:

2 year limited warranty with lifetime supportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 days

Laboratory Laser Welder For Battery Prismatic Cell Top Case Welding

1、 Equipment Overview

This equipment is used for sealing welding and liquid injection hole welding of the top cover of square aluminum shell batteries, and is a semi-automatic equipment. The incoming top cover has been manually buckled into the aluminum shell. With the battery sealing surface as the upper benchmark, it is positioned from the top of the cell bottom plate. After laser welding, it is manually detected and judged. This device can quickly replace fixtures and is suitable for welding multiple models of products.

2、 Technical parameters

1. Incoming material parameters

|

No |

Item |

Specification |

Note |

|

1 |

Blueprint cell size |

Length 153.5mm, Thickness 54mm, Height 173.5mm |

|

3、 Process performance

1. Hardware accuracy

|

No |

Item |

Technical parameter |

Note |

|

1 |

Effective working range of the workbench |

300mm long × 300mm wide × 200mm high |

|

|

2 |

Repeated positioning accuracy of laser welded joints |

≤ ± 0.02mm |

|

|

3 |

Qualification rate |

98.5% |

|

|

4 |

efficiency |

50-70mm/s |

|

|

5 |

The fixture can be replaced |

|

|

|

6 |

Welding method |

Vertical welding and side welding (corresponding fixtures are required) |

|

|

7 |

Laser welding machine power |

4000W |

|

|

8 |

Welding head focal length adjustment accuracy |

0.02mm |

|

|

9 |

Welding parameter memory function, no need to program again to switch products that have already been made |

|

|

|

10 |

Equipped with dust and smoke removal function |

|

|

|

11 |

Equipped with safety door and Light curtain to ensure safe work |

|

|

|

12 |

Noise |

≤ 75db |

|

|

13 |

Failure rate |

Fault rate=(fault shutdown time/equipment usage time)<2% |

|

2. Product accuracy

|

No |

Item |

Standard |

|

1 |

Welding flange width |

< 0.3mm |

|

2 |

Weld penetration depth |

Melting depth 0.5~1.4mm, melting width 1~1.6mm, |

|

3 |

Weld seam pressure resistance (tensile strength) |

Withstand voltage > 1.1Mpa |

|

4 |

Appearance and welding quality |

After welding, the weld seam is free of defects such as pits, broken welds, misalignment, and bursting points, and the weld seam is smooth and flat, without causing serious deformation of the shell. After welding, there is no welding slag inside the shell, and the laser does not burn the internal diaphragm and high-temperature tape of the shell |

4、 Main component configuration

Equipment composition:

1. Top cover welding battery fixture part

|

No |

Description |

Parameter |

|

1 |

Manually load the material, using the sealing surface of the battery cell as the benchmark, and lift it up from the bottom of the battery cell to ensure consistency in the upper benchmark; The long side cylinder is locked, the short side cylinder is locked, and the upper reference cylinder is unlocked. The lower end of the fixture adopts a spring positioning mechanism, with elastic deformation of the spring to ensure that the battery cell shell is not scratched during precise positioning; |

|

|

2 |

Pre weld the cover plate and shell first, fix the position, and then fully weld. |

|

|

3 |

The clamping part is not in overall contact with the battery cell, and the middle is hollowed out to prevent excessive squeezing pressure on the battery cell; Manual cutting, the battery moves to the cutting position, the battery cylinder unlocks, the battery cell pops up, and the material is manually picked up. The short side is clamped by a rotating cylinder, and the battery cell is placed from the side for easy operation. |

|

2. Three axis welding platform part

|

No |

Description |

Parameter |

|

1 |

The laser output head is driven by a three-axis high-precision mechanical module to ensure hardware accuracy, and comes with its own; Adopting high-precision algorithms and controllers, precise laser excitation power and path; Before welding, press the installation mechanism and tighten the top cover before full welding to ensure the product qualification rate; The exhaust duct and filter are made of flame-retardant materials, and the connecting parts are connected with steel rings. |

|

3. Rack cover and human-machine interface part

|

No |

Description |

Parameter |

|

1 |

The upper cover of the equipment is composed of sheet metal and tawny acrylic panels, and Light curtain is installed to ensure the safety of operators. The man-machine interface of the equipment is designed according to the existing structure of the company, and the welding parameters are visible and traceable. |

|

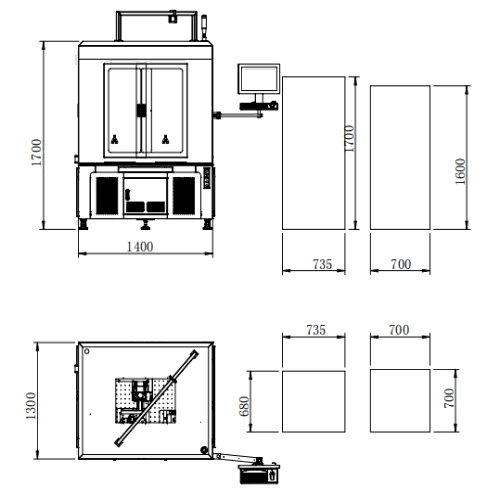

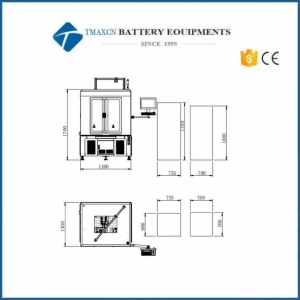

4. Equipment three view section

5、 Equipment Capability Requirements

|

No |

Item |

Index |

Note |

|

1 |

Time movement=actual movement time/load time * 100% Actual operating time: load time - planned downtime (faults, material switching) Load time: Production hours - Planned downtime Production hours: normal working hours Planned downtime: morning and evening, rest, spot checks, cleaning, etc |

≥99.00% |

|

|

2 |

2. Performance time=Theoretical beat * Actual production quantity/Actual production time * 100% Theoretical beat: Theoretical production time for a single product |

100% |

|

|

3 |

Product qualification rate=Number of qualified products produced/(Input quantity - Fixed loss - Startup debugging - Sampling quantity) * 100% Fixed losses: tape splicing, roll changing, etc |

≥99.50% |

|

|

4 |

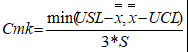

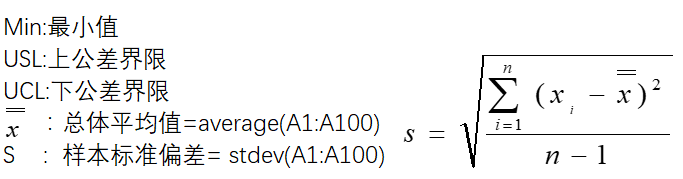

CMK Equipment Capability Index The CMK index only considers short-term dispersion and emphasizes the impact of equipment factors on product quality. Test requirements: The extracted data is continuous; Assuming that the operator, measuring tools, and raw materials are not affected; Only consider the influence of a single device factor. (i.e., the operator must be proficient and competent; the measuring tools must meet the requirements and have been calibrated; the same batch of materials; and the inspection personnel must meet the requirements.) Generally, 10 sets of 100 samples are sampled for measurement within approximately one hour after the stable production of the machine.

|

≥1.67 |

|

|

5 |

Equipment operation plan

|

300 days/year, 2 shifts, (11.5) hours/shift |

|

|

6 |

Equipment lifespan |

10 years |

|

|

7 |

Operator |

|

|

|

8 |

Equipment noise |

≤ 75dB |

|

6、 Component brands and spare parts

1. Main component brands

|

No |

Name |

Brand |

Place of origin |

|

1 |

Welding laser |

Chuangxin |

|

|

2 |

Welding head |

Wan Shunxing |

|

|

3 |

Chiller |

Dongluoyang |

|

|

4 |

Motion module |

Shangyin |

|

|

5 |

servo motor |

Xinjie/Huichuan/Panasonic |

|

|

6 |

Rack+large board+cover |

customization |

|

|

7 |

Observing the CCD+display |

customization |

|

|

8 |

Dust collector |

foxconn |

|

|

9 |

Welding platform motion control |

customization |

|

|

10 |

Welding control software |

customization |

|

|

11 |

Laser waveform control card |

customization |

|

|

12 |

Industrial computer |

Advantech/Lenovo |

|

|

13 |

Fixture |

customization |

|

2. List of Special Tools

|

No |

Name |

Brand |

Quantity |

Note |

|

1 |

Hex key |

|

1 set |

|

|

2 |

|

|

|

|

|

No |

Name |

model |

Quantity |

Note |

|

1 |

Top cover welding machine |

TMAX-HJ-4000 |

1 set |

|

|

2 |

Chiller |

Dongluoyang |

1 unit |

|

|

3 |

Dust collector |

foxconn |

1 unit |

|

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat 13506084915

Wechat 13506084915