- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

0-250ML Electrolyte Filling Machine For Prismatic Battery Making

Model Number:

TMAX-EFM250Type:

Electrolyte Filling MachineCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

0-250ML Electrolyte Filling MachineFor Prismatic Battery Making

*Multi stage filtration device and special material adsorption system are adopted to effectively ensure smooth valve pipeline, protect the vacuum pump from corrosion damage and block the pump blade from being able to start vacuumizing.

*In the process of liquid injection, the electrolyte is rarely exposed inside the glove box, which greatly reduces the volatilization and corrosion resistance of other glove box components.

*Due to the high water content, the glove box must be filled with nitrogen to purify the precipitation, which costs a lot of time. The pipeline and filter device are arranged in the place convenient for operation of personnel inside the glove box. The filter device is convenient for disassembly and assembly, eliminating redundant accumulated residual liquid, and greatly reducing the cleaning times. In addition, in case that the joint pipeline is blocked and DMC cleaning is still unable to solve the problem, it can be easily and conveniently removed through the glove box operation port to dredge the pipe without removing the glass and entering the glove box to remove the pipe for drainage Clean and maintain the working environment.

*With DMC cleaning function, mainly for monthly and quarterly cleaning to make the pipeline clean.

*Special two-way pneumatic valve is not blocked, and SUS316 and PTFE materials inside have strong corrosion resistance.

*It has extremely high measurement accuracy and repeatability consistency, and the accuracy of electrolyte is plus or minus 1%.

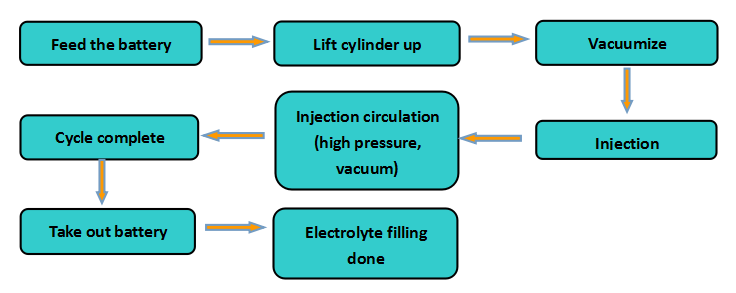

*The method of vacuum before liquid injection, vacuum and pressure alternately after liquid injection has high efficiency, accurate accuracy, convenient and reliable operation.

*The vacuumizing time, high vacuum value, low vacuum value, liquid injection volume, standing time, pressure time and pressure relief time can be set to be adjustable.

*Anti corrosion, long life design, key parts using imported components.

*The fixture is easy to assemble and disassemble to adapt to different height products.

*Exquisite appearance, stable performance.

Specifications

Filling accuracy

±1%

Filling volume

0~250ml adjustable

Vacuum

During electrolyte injection, the vacuum pressure shall be kept above -98kpa ( vacuum pump provided by the customer).

Parameter setting

The vacuumizing time, low vacuum degree, liquid injection standing time, pressure and time can be adjusted.

Machine frame

The joint of liquid injection tank body is made of stainless steel, the hose is made of corrosion-resistant PE hose, the body is made of 6 series aluminum alloy, and the whole machine is corrosion-resistant.

Nitrogen

≥0.4MPa

Voltage

AC220V

Power

1.5KW

|

Filling accuracy |

±1% |

|

Filling volume |

0~250ml adjustable |

|

Vacuum |

During electrolyte injection, the vacuum pressure shall be kept above -98kpa ( vacuum pump provided by the customer). |

|

Parameter setting |

The vacuumizing time, low vacuum degree, liquid injection standing time, pressure and time can be adjusted. |

|

Machine frame |

The joint of liquid injection tank body is made of stainless steel, the hose is made of corrosion-resistant PE hose, the body is made of 6 series aluminum alloy, and the whole machine is corrosion-resistant. |

|

Nitrogen |

≥0.4MPa |

|

Voltage |

AC220V |

|

Power |

1.5KW |

Equipment configuration

|

No. |

Item name |

Quantity |

Unit |

|

1 |

Electrolyte injection station |

1 |

Set |

|

2 |

Automatic liquid injection mechanism |

2 |

Set |

|

3 |

Electric metering pump (ceramic pump) |

1 |

Set |

|

4 |

Vacuum pump or pipeline vacuum (- above 98kpa)→not included in the standard package |

1 |

Set |

|

5 |

Bracket |

2 |

Set |

|

6 |

Battery positioning mechanism |

2 |

Set |

|

7 |

Pressure nozzle mechanism of injection nozzle |

2 |

Set |

|

8 |

Electrolyte transfer tank |

1 |

Set |

|

9 |

Electrolyte filtration system |

1 |

Set |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com