- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

1200°C Max Magnet Driven Sliding Tube Furnace For DVD & RTP

Model Number:

TMAX--1200X-S-DVDCompliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

1200°C Max Magnet Driven Sliding Tube Furnace For DVD & RTP

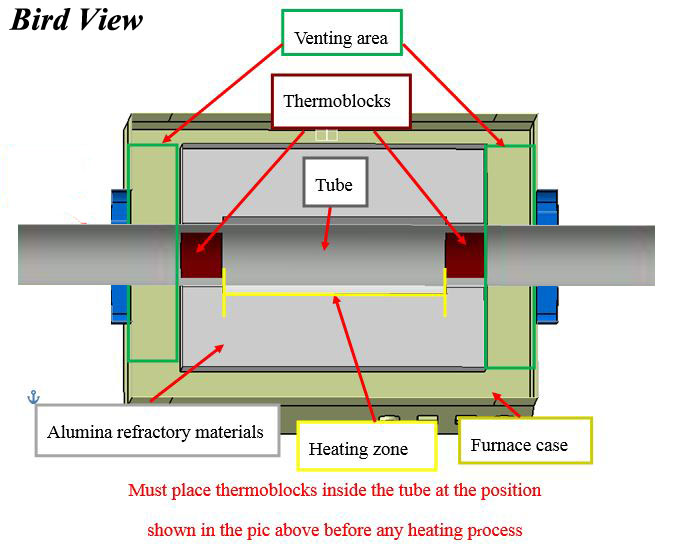

TMAX-1200X-S-DVD is a compact megnet driven sliding 2" tube furnace with a max. working temperature of 1200°C, which is designed for direct vaporizing deposition (DVD) or rapid thermal processing (RTP) under various atmosphere for 2D material growth.

SPECIFICATIONS:

|

|

|

Furnace Power |

|

|

Max. Temperature |

1200°C (<1 hour) |

|

Continuous Temperature |

1100°C ( continuous) |

|

Max. Heating Rate |

<= 20 °C/min |

|

|

|

Temperature Controller

|

|

|

Temperature Accuracy |

+/- 1°C |

|

Heating Elements |

Fe-Cr-Al Alloy doped by Mo |

|

|

|

|

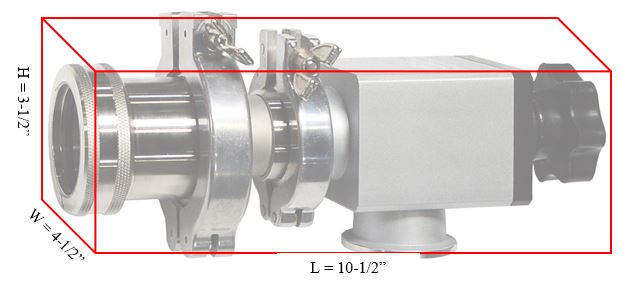

Vacuum Flanges

|

2" default flange with 1/4'' Bard fittings, 1/4'' tube feedthrough port (for 1/4" O.D thermocouple insert) and a KF25 vacuum port(click picture below to see details ) |

|

Vacuum Level |

10-2torr (by mechanical pump) |

|

|

|

|

With lid close: 1055mm (L) × 300mm(W) × 400mm(H) |

|

|

Net Weight |

22 Kg |

|

Shipping Package Size |

48''(L) x 24''(W) x 28''(H) |

|

Shipping Weight |

120 lbs |

|

Warranty |

Two years limited warranty with lift time support (Consumable parts such as processing tubes and O-rings are not covered by the warranty. |

|

Laptop, software & WiFi Control(Optional) |

|

|

|

|

|

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com