- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

1200C Three Zones CVD Tube Furnace With 4 Channel MFC Gas Station

Model Number:

TMAX-3-1200Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

1200C Three Zones CVD Tube Furnace With 4 Channel MFC Gas Station

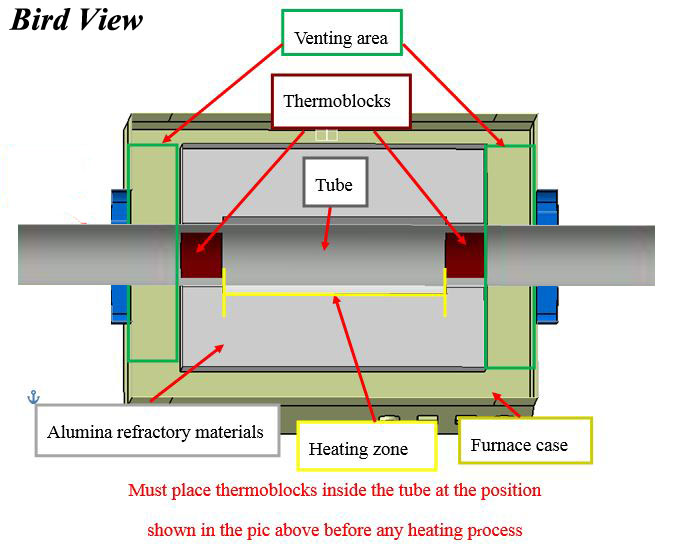

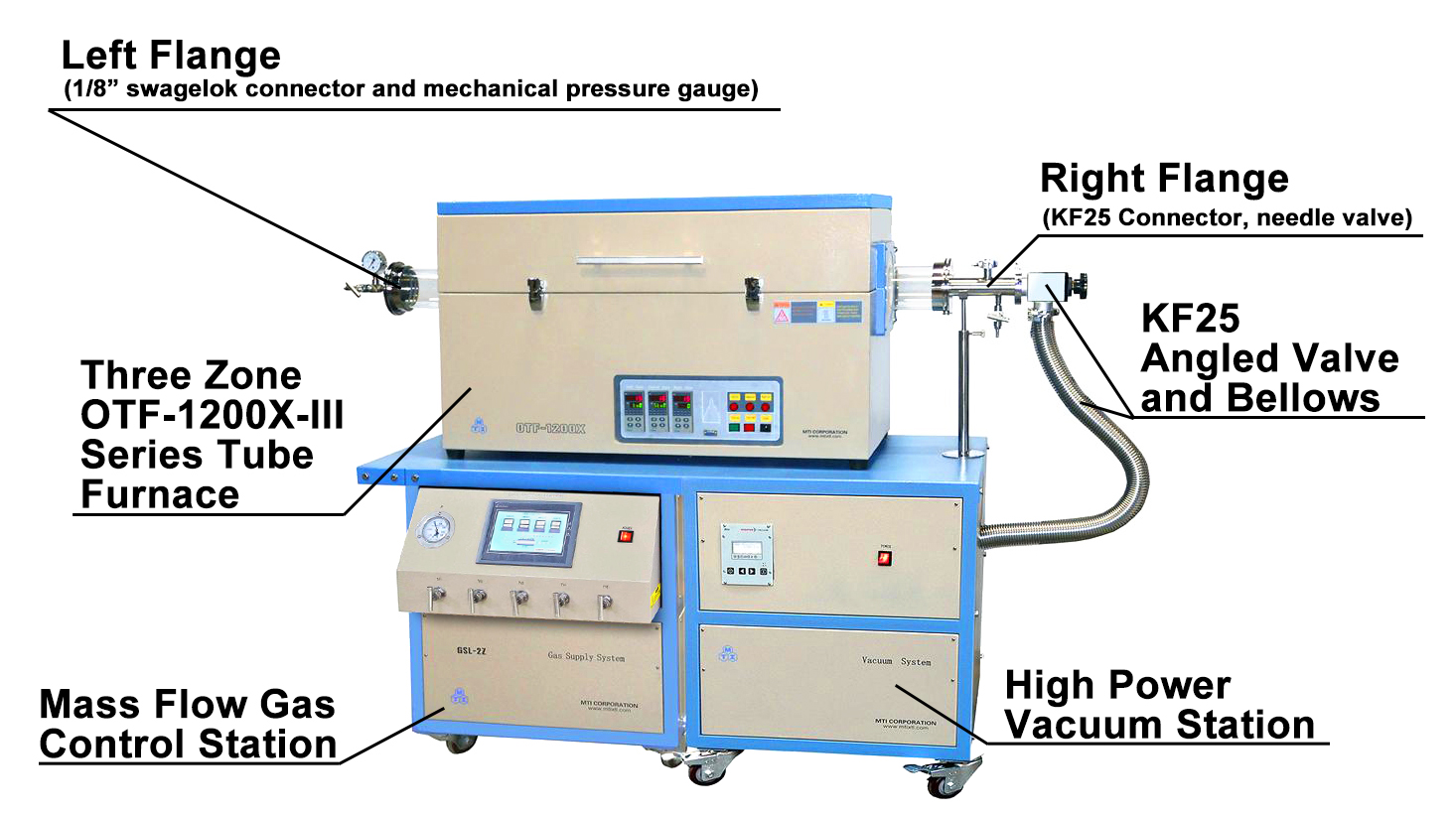

The TMAX-3-1200 series furnace workstation consists of three-zone tube furnace, a precision mass flow gas control station, a high vacuum station and other assembling parts. The max. working temperature of this workstation is 1200°C. The ultimate vacuum rate goes to 10^-5 torr (with our sealing assembly provided). The mass flow gas control station mixes several kinds of gas together and input the mixed gas into a fused quartz tube inside the furnace. It is competent for the experiments as CVD, Diffusion and other thermo-treatments under vacuum status and shielding gas protection.The furnace comes with a 4-channel digital LED display mas flow gas control station.

Specifications

|

tube furnace |

Casing |

Double layer steel casing with air cooling. |

|

Processing Tube |

Material: Fused quartz tube |

|

|

|

|

|

|

Power |

7KW |

|

|

Rated Voltage |

AC 208-240V Single phase, 50/60Hz |

|

|

Heating Element |

Fe-Cr-Al Alloy doped by Mo |

|

|

Working Temp. |

Max. Heating Temp.: 1200°C |

|

|

Heat-up Rate |

Heat-up rate: 1~20°C/min programmable |

|

|

Heating Zone Length |

Total heating zone: 900mm (300mm + 300mm + 300mm) |

|

|

Temp. Controller |

|

|

|

Vacuum Seal |

One pair of stainless steel vacuum flange with: |

|

|

Rated Voltage |

AC 208-240V Single Phase, 50/60Hz |

|

|

Dimension |

1100(L) x 450(W) x 670(H), mm |

|

|

High Vacuum Station

|

Structure |

Mobile cart size: 600 (L) x 600 (W) x 700(H), mm |

|

Volume Flow Rate |

Nitrogen N2 33 L/s |

|

|

Working Range |

From 1000 mbar to <1E-7 mbar |

|

|

Ultimate Pressure |

<1E-8 mbar (without any leaking ) |

|

|

Voltage & Power |

110VAC or 220VAC, 110W |

|

|

Mass Flow Gas Control |

Structure |

|

|

Power |

18W |

|

|

Rated Voltage |

AC 208-240V, Single phase, 50/60Hz |

Shipping & Warranty

|

Shipping Dimension |

Total Three Pallets ( #1: 60" x 45" x 40" #2: 48" x 40" x 42" #3: 48" x 40" x 42" ) |

|

Shipping Weight |

850 lbs |

|

Warranty |

Two years limited warranty |

|

Compliance |

|

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com