- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

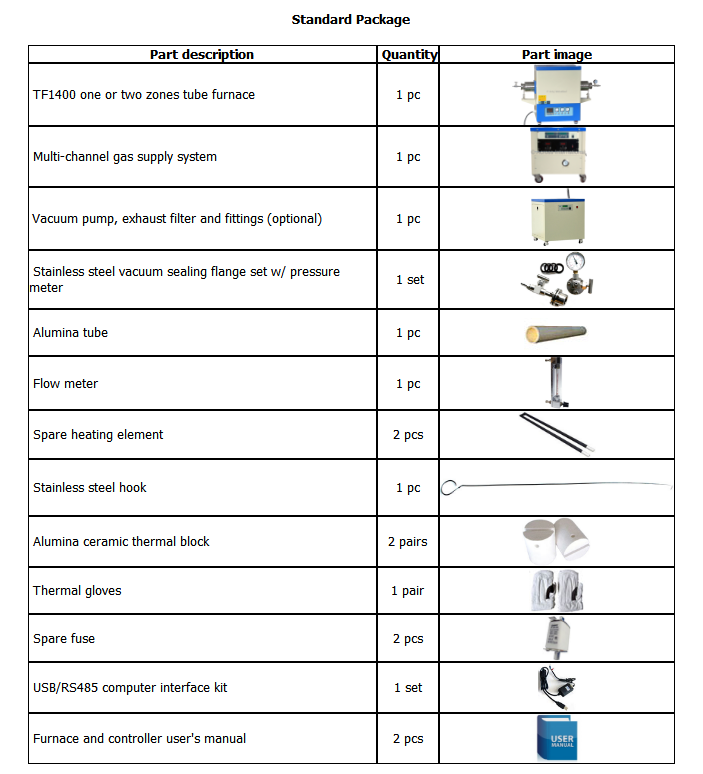

1400°C CVD Tube Furnace With Gas Mixing & Pumping System

Model Number:

TMAX-1400PECVDCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

1400°C CVD Tube Furnace With Gas Mixing & Pumping System

VACUUM PUMP MOBILE CART ONLY AVAILABLE IF YOU PURCHASE A PUMP AND A DIGITAL VACUUM CONTROLLER.

TMAX-1400PECVDseries Chemical Vapor Deposition (CVD) tube furnaces feature a chamber with Mitsubishi (Japan) high quality alumina fiber insulation and SiC heating elements. A dual-wall steel internal housing helps minimize heat loss to exterior surface.

Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results. All our furnaces are CE compliant.

Features

· Standard package includes set of stainless steel vacuum sealing flanges with valves and pressure meter.

· Dual flanges support ensures better sealing and longer tube life.

· Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

· Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

· Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

· Built-in computer interface.

· Long life type S thermocouple

Safety

· Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

· Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Warning! NEVER fill furnace with explosive gases, including Hydrogen, Carbon Monoxide and Methane.

Specifications

|

Tube Material |

High purity (99%) Al2O3 alumina |

|

Min/max./Constant Working Temperature |

Ambient / 1400°C (2552°F) / 1300°C (2372°F) |

|

Refractory Lining |

Mitsubishi(Japan) high quality 1600 grade fiber alumina |

|

Heating Element |

Silicon carbide (SiC) |

|

Thermocouple Type |

S |

|

Temperature Controller |

Shimadenfp93

(Japan) with 4 programs and 40 segments |

|

Max Heating & Cooling Rate |

5°C (41°F)/min above 1200°C and 10°C (50°F)/min below 1200°C (2192°F) |

|

Temperature Controller Precision |

+/- 1°C (+/- 1.8°F) |

|

Vacuum Sealing Flange Kit |

Stainless steel vacuum sealing

flanges with one mechanical |

|

Electrical requirements |

208-240VAC, 50/60 Hz, single phase |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com