- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

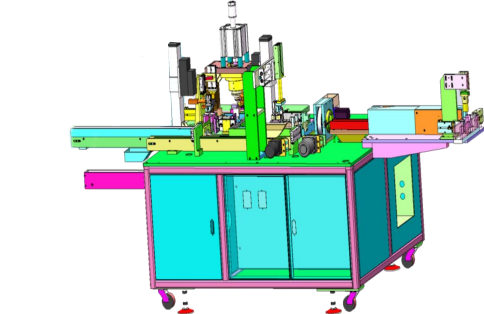

18650, 21700, 26650, 32650 Cylindrical Cell Semi Auto Bottom Welding And Grooving Two-In-One Machine

Model Number:

TMAX-DDGC-BCompliance:

CE CertifiedWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

18650, 21700, 26650, 32650 Cylindrical Cell Semi Auto Bottom Welding And Grooving Two-In-One Machine

This is a bottom welding and grooving two-in-one machine, the two machines also can be used separately. It is a connected device designed for customers to weld the bottom of the cylindrical battery and the grooving at the mouth of the steel cans.

It is suitable for 18650, 21700, 26650, 32650 cylindrical cell with different dies.

Bottom Welding Part

(1) When the battery is fed, the feeding cylinder pushes the battery to the spot welding position, and the discharge cylinder discharges the material after the spot welding is completed.

(2) When the battery reaches the needle removal position, the needle pulling cylinder will automatically pull out the spot welding needle and put it into the needle receiving box.

Grooving Part

(1) The battery after finished bottom welding enters the grooving assembly line.

(2) When the equipment senses that there is material at the feeding pusher plate, the pusher cylinder will send the battery to grooving part.

(3) The upper head presses down, and then the main motor rotates to drive the battery to rotate. At this time, the hob moves forward with the ejector roller at the same time, and then the head cylinder presses down to complete the grooving. The battery is discharged directly.

Machine process

|

Step |

Process |

|

1 |

Load the array of batteries to be spot welded into the feeding chute. |

|

2 |

Batteries flow to the end of the chute and enter the spot welding position mechanism. |

|

3 |

Trigger sensors activate automatic welding. |

|

4 |

Automatically retract the welding pin, the battery moves out with the pull tape and meets the grooving machine. |

|

5 |

Batteries from the previous process load onto the feeding pull tape. |

|

6 |

As the pull tape reaches the end, the pusher cylinder pushes the battery to the grooving station. |

|

7 |

After the core shaft presses down, the grooving roller wheel secures the battery, and the grooving knife advances with the cam to groove. |

|

8 |

After grooving, the dust is extracted and the battery is pushed onto the discharge pull tape, repeating the next cycle. |

Technical parameters

|

Parameter |

Description |

|

Power Supply |

AC220V*3P/50Hz |

|

Compressed Air |

≥0.6MPa 5L/min |

|

Equipment Weight |

0.3T |

|

Dimensions |

Length 1540mm, Width 800mm, Height 1800mm |

|

Coating Color |

Exteriors requirement: Aluminium alloy + PC acrylic board for the casing, other parts are painted, with a uniform spray of computer white except stainless steel, surface treated, and plated parts |

|

Production Capacity/Speed |

30PPM (for 18650 battery as reference) |

|

Product Qualified Rate |

≥99.9% |

|

Equipment Failure Rate |

<5% |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com