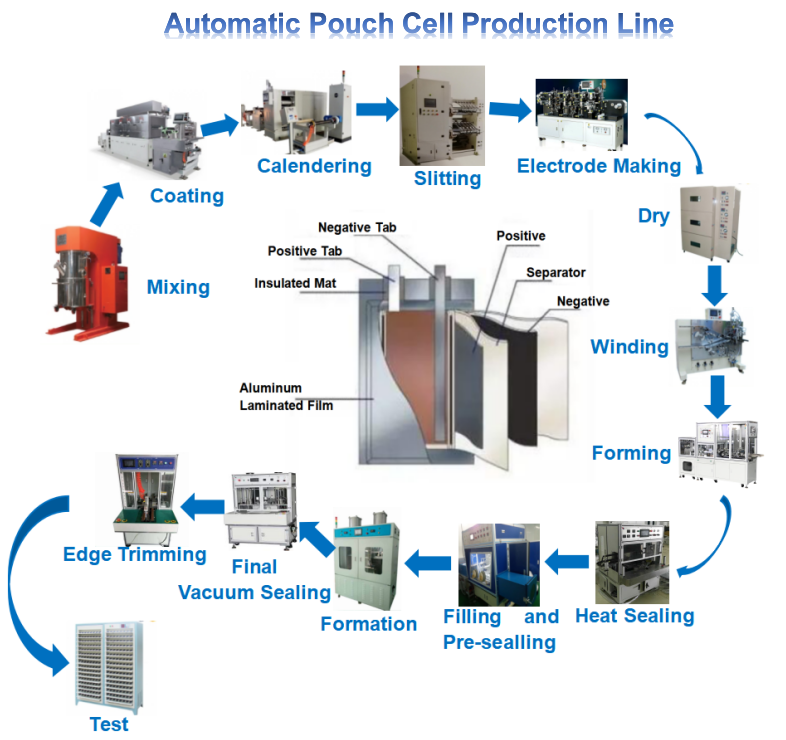

- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

200L Planetary Vacuum Mixer For Lithium Battery Slurry

Model Number:

TMAX-PV-200LNet Weight:

about 4.0 TonsCompliance:

CE CertificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

200L Planetary Vacuum Mixer For Lithium Battery Slurry

The vacuum planetary mixer is programmable in vacuum operation , raise or down, speed adjusting by the frequency inverter , temperature show/control , urgent stop , and so on.

It is excellent for preparing LiCoO3, LiFePO4, Phosphors...electrode slurry and ceramic slurry without gas bubble.

Technical Parameters

|

Viscosity range |

12,000-20,000 cp |

|

Volume |

Design volume: 265L, effective volume: 200L |

|

Mixing barrel |

φ750mm, depth 600mm |

|

Machine material |

SUS304 |

|

Power |

15KW |

|

Vacuum degree |

-0.098Mpa |

|

Temperature control range |

20~90℃ |

|

Lifting stroke |

700mm |

|

Dimensions |

L2400mm x W1600mm x H2750mm |

|

Machine weight |

about 4.0 tons |

Safety protection

1. There is an audible and visual alarm when the mixing tank rises or falls;

2. After the mixing tank is in place, the mixer can work;

3. The barrel body cannot be raised and lowered when the mixer is working;

4. Automatic protection of electrical appliances; emergency stop protection for operators;

5. Mixer, electrical cabinet and control box should be grounded.

Equipment technical parameters:

1, the equipment is suitable for viscosity: 1 thousand -20,000 cp;

2, the total power: about 37kw;

3. Vacuum: ≤-0.098Mpa;

4. Positive pressure of water-cooled jacket of mixing tank: ≤0.4Mpa.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com