- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

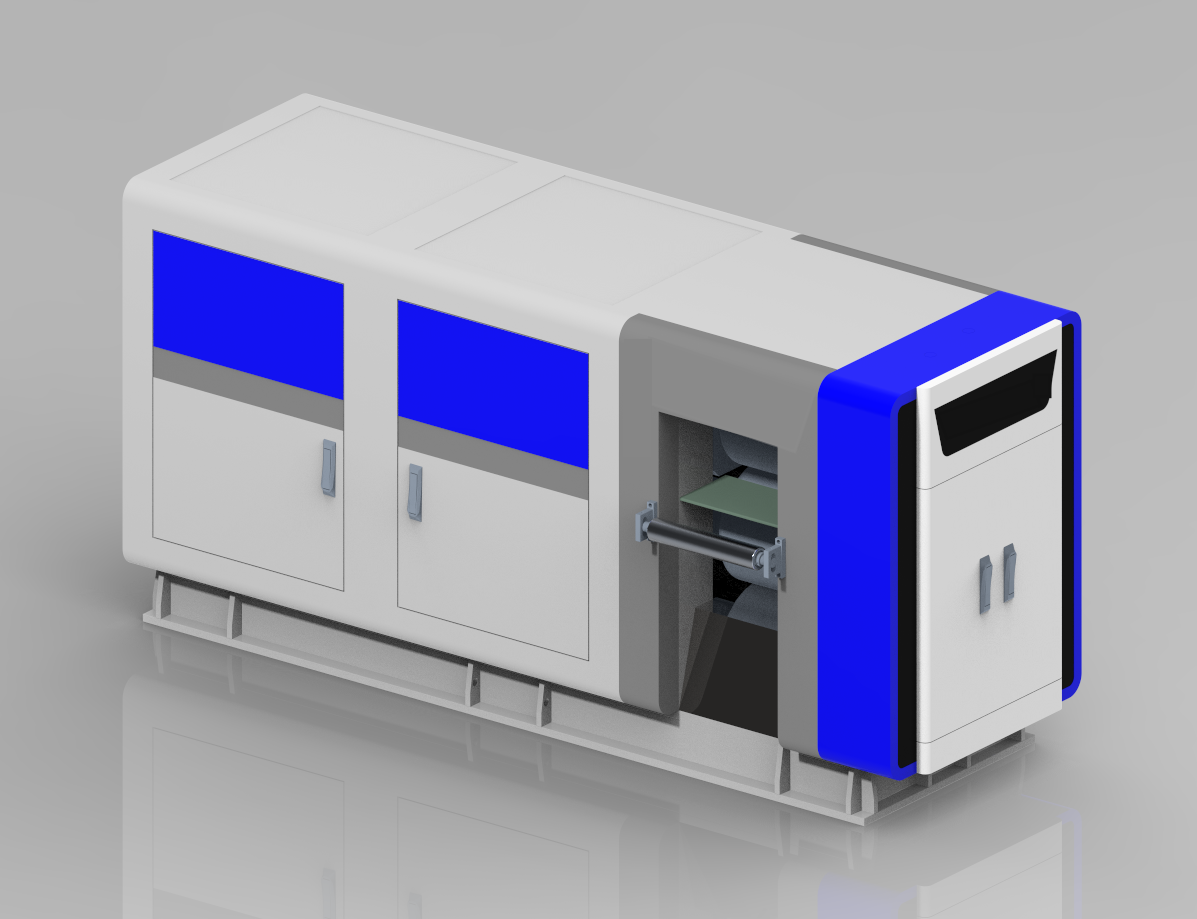

Ф 300 * 400 High Precision Continuous Roller Press Production Line

Model Number:

TMAX-Ф 300 * 400Warranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Ф 300 * 400 High Precision Continuous Roller Press Production Line

1. Functional Overview

Rolling machine is the main equipment in the continuous rolling production line, which is composed of rigid frame, roller auxiliary, universal coupling, motor reducer, gas-liquid pressurization system, gap adjustment system, electrical control system, feeding guard plate and roller surface cleaning mechanism.

The main function is to make the pole sheet under the roll, so that the pole sheet reaches the appropriate compactness, and reach the pole sheet thickness requirements according to the coating thickness. This equipment adopts the ball wire bar and wedge iron gap to adjust the roll clearance, and the linear speed is adjusted by the frequency converter.

2. Parameter

2.1 Configure the power supply

Three-phase five-line AC380V, 50Hz, voltage fluctuation range: + 10%~ 10%; the maximum starting power of the equipment is 13kW.

2.2 Compressed air

0.6MPa~0.8MPa, Air pressure fluctuation ± 1% (clean air after water, oil, filtration and pressure stabilization), compressed air consumption: 0.3m3 / h.

2.3 Specification

1) Equipment weight: about 3 tons.

2) Size: L (760mm) * W (2350mm) * H (1145mm) (including electric cabinet, excluding maintenance operation channel)

3) Appearance color: Yujia standard color (computer gray) / customers can choose the color

4) Structure diagram: see the equipment layout diagram

2.4 Environmental requirements

1) Ambient temperature: 25 ± 3℃

2) Relative humidity: 10% ~ 30% RCH, to ensure that the site air is dry and smooth, free of acid and alkali corrosion

3) Ground wire: protective grounding

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com