- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

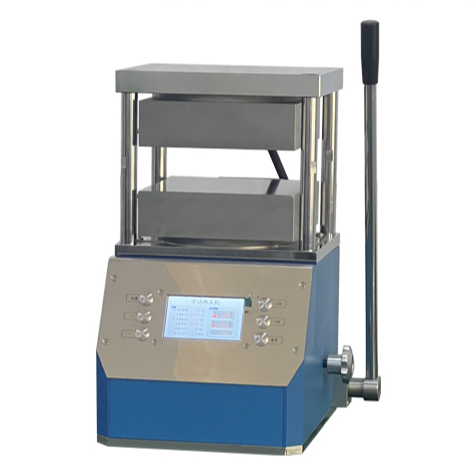

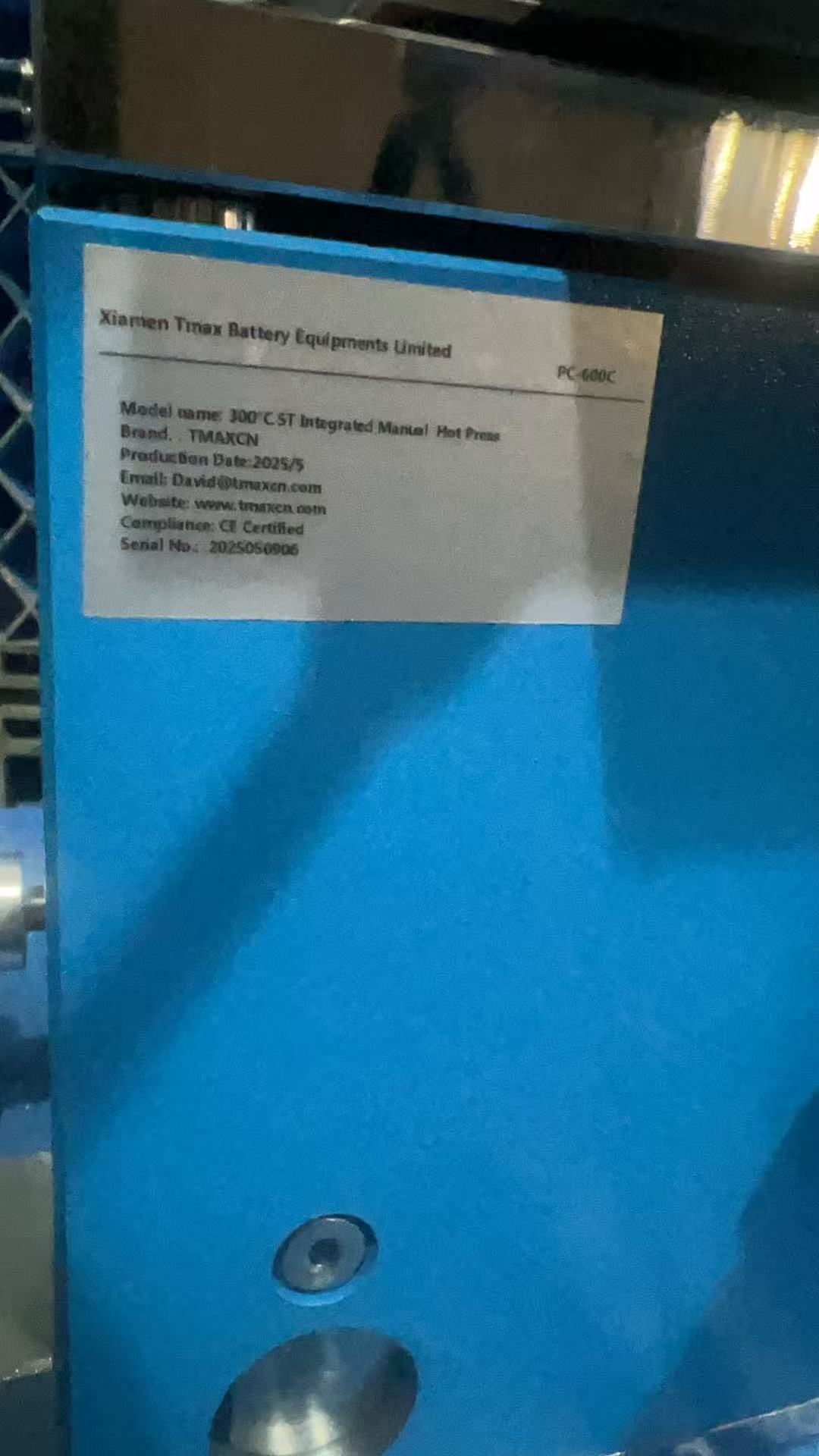

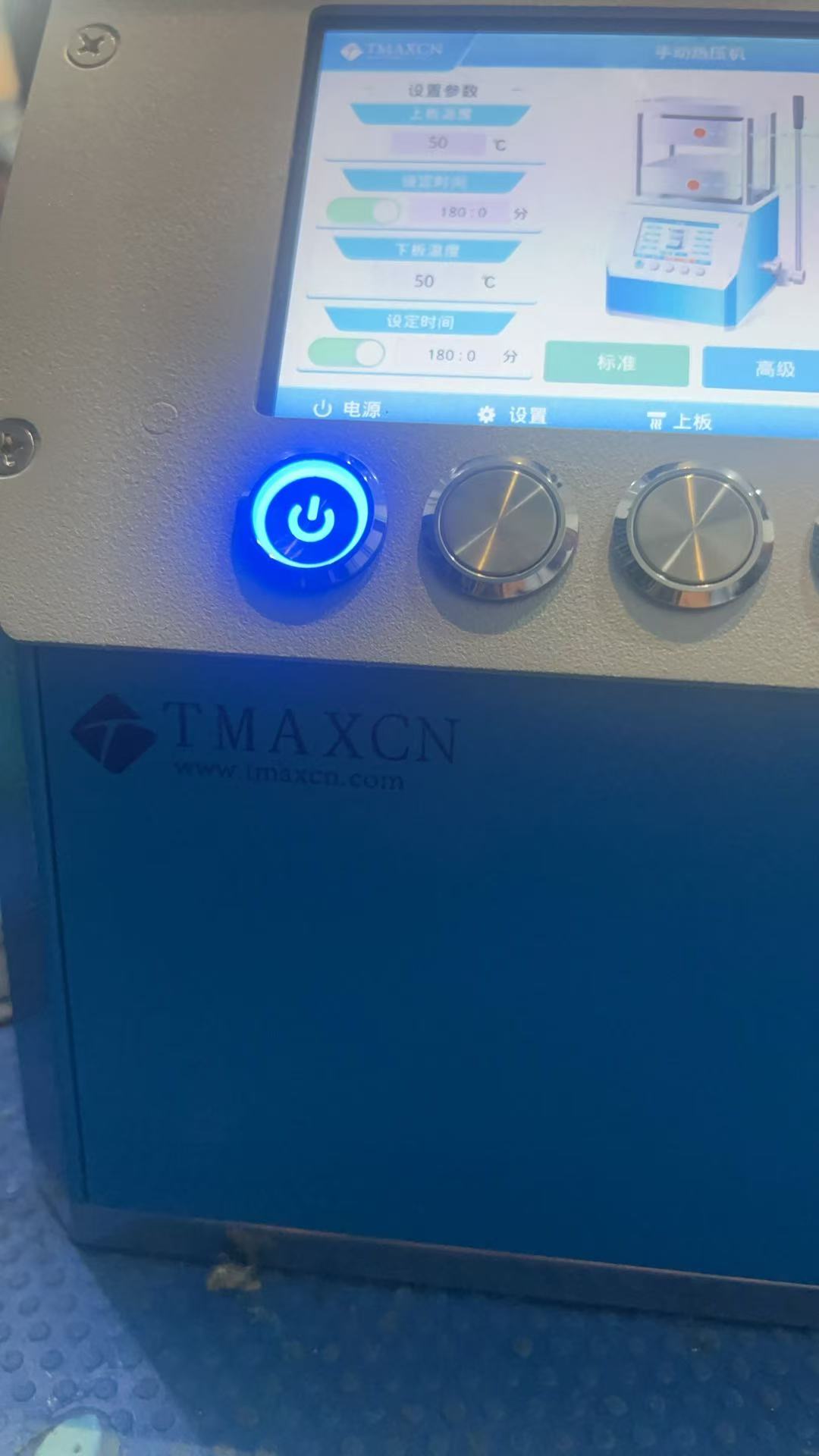

300C 500C Integrated Laminating Manual Heat Press Machine

Model Number:

TMAX-PC-600C/CGCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

3 Days

300C 500C Integrated Laminating Manual Heat Press Machine

Application field

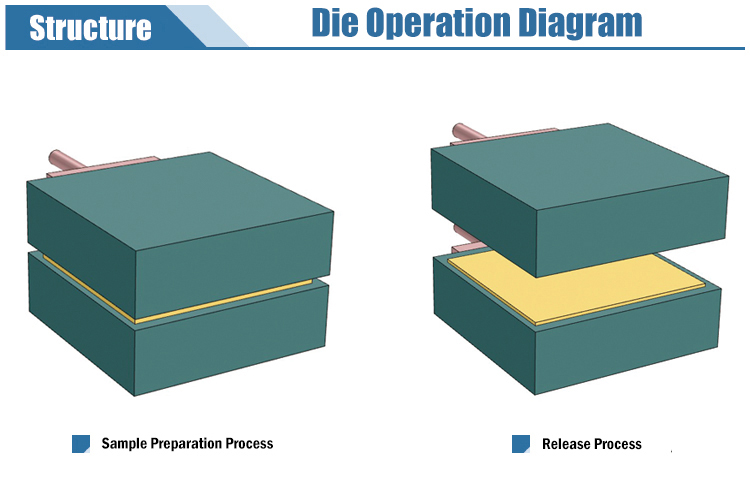

We are a professional manufacturer of hydraulic powder presses and dies. Our hydraulic presses feature small size , high pressure and high pressure control accuracy , and have been widely applied in scientific research , teaching, testing and chemical engineering. In addition, the products can be used together with Fourier infrared spectrometer, fluorescence spectrophotometer and other testing instruments to substitute for imported products.

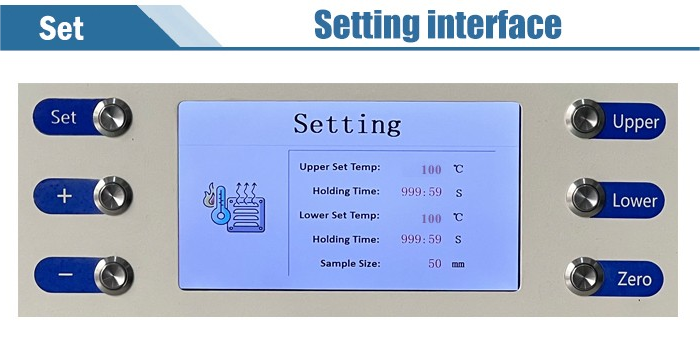

Set

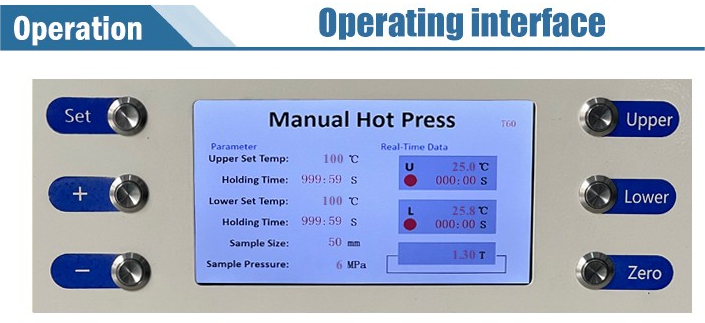

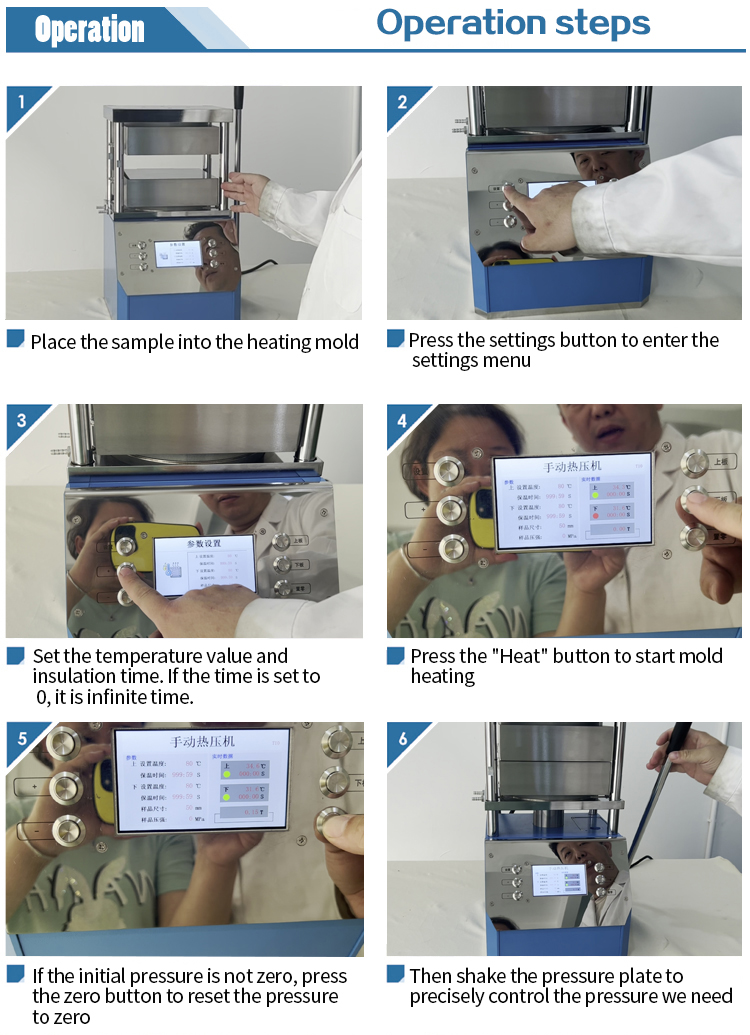

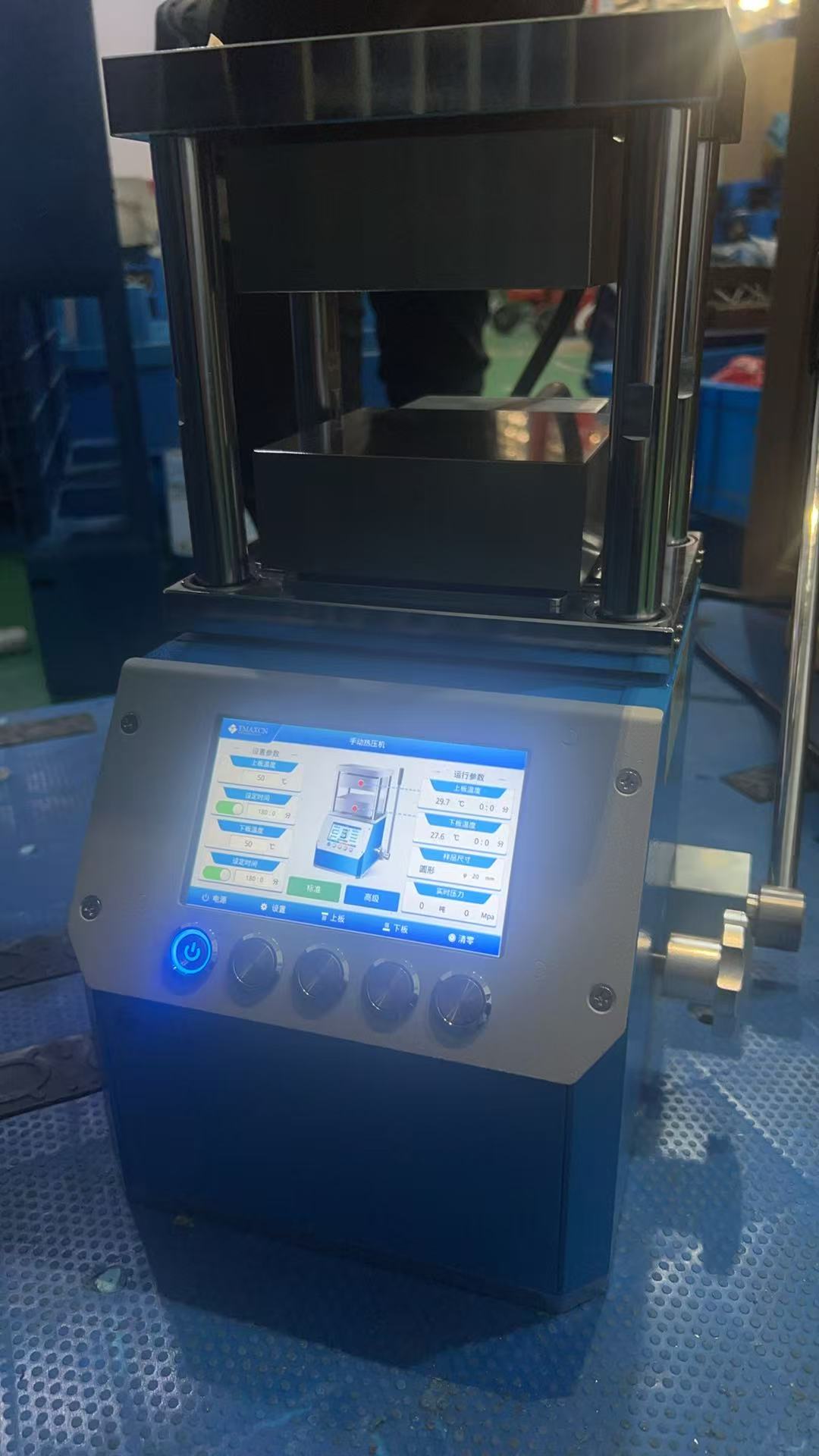

Set: In the operation interface, press the settings button to enter the settings interface, then press the settings button to move the settings content. After moving to the mold diameter, press the settings button again to return to the operation interface. Note: When the time is set to "0", it means that the time is set to infinity.

+: In the operation interface, press the "+" key to increase the setting number.

-: In the operation interface, press the "-" key to reduce the setting number.

Upper: Press the "Upper Plate" button on the operation interface, and the upper plate will start heating to the set temperature. After the automatic timing and constant temperature timer are completed,the heating will stop.Or press the "Upper Plate" button again to stop heating the upper plate. During the heating process, all setting buttons are invalid.

Lower: Press the "Lower Plate button on the operation interface, and the lower plate will start heating to the set temperature. After the automatic timing and constant temperature timer are completed,heating will stop.

Zero: If the sample is not in contact, but the device has already displayed pressure, it may be due to the weight of the heating plate. We can press the "reset" button to reset the pressure to zero.

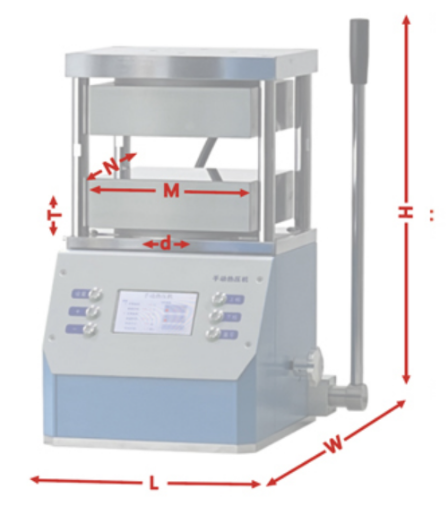

Technical parameters

|

Instrument model |

PC-600C/CG(500℃) |

|

Pressure range |

0-5.0 tons |

|

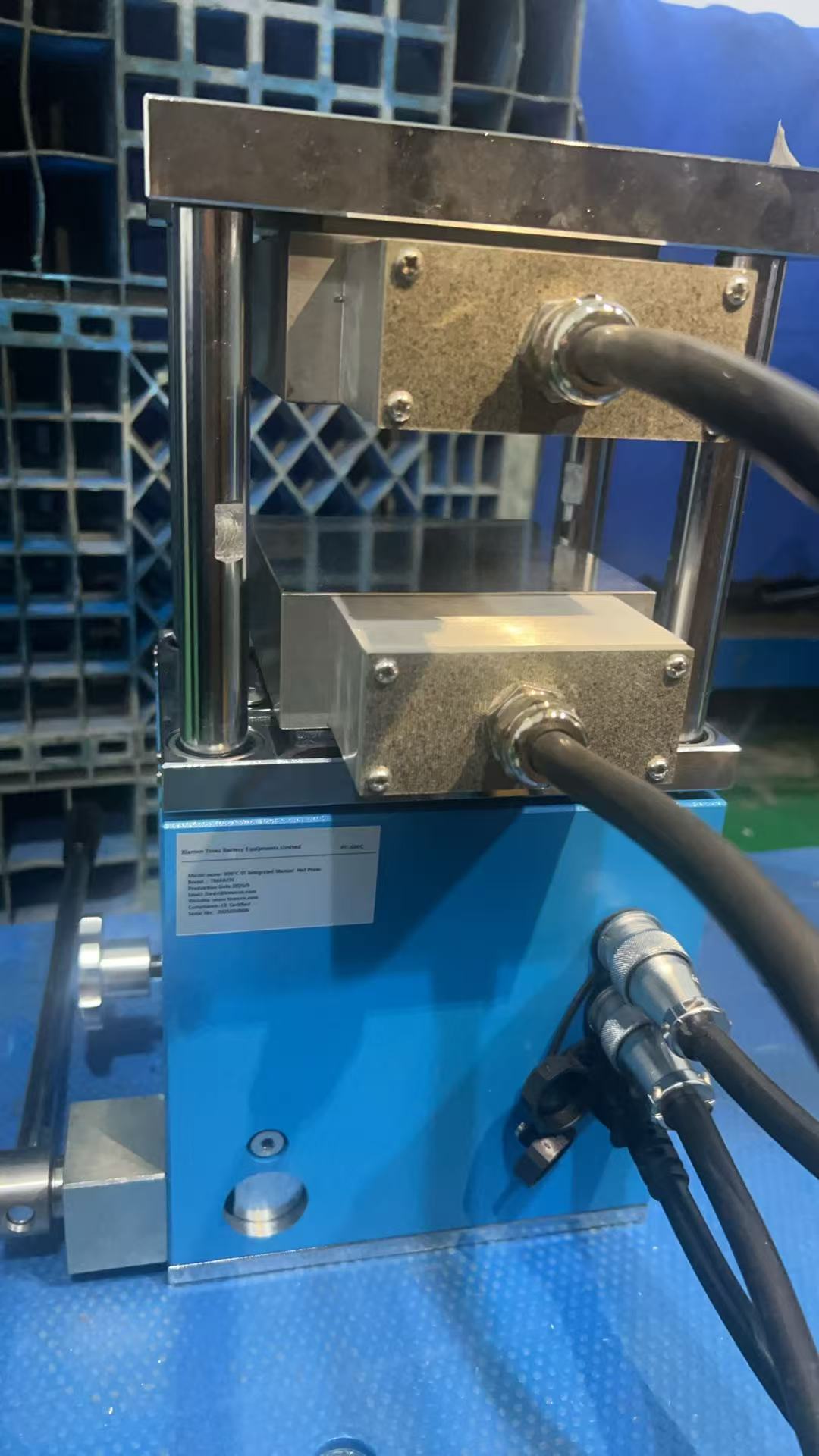

Piston diameter |

Chrome plated cylinder φ50mm (d) |

|

Overall structure of main body |

Equipment without sealing connection to reduce oil leakage point |

|

Mold heating temperature |

Room temperature -300.0℃/500.0℃ |

|

Constant temperature time |

1 second~∞ second |

|

Temperature control precision |

0.1℃ |

|

Insulation method |

Imported heat insulation board |

|

Cooling method |

Water-cooled rapid cooling [water cooler optional] |

|

Mould size |

Double plate heating 120*120mm(M*N) |

|

Working space |

140*140*60mm |

|

Size of the whole machine |

250*230*390mm (L*W*H) |

|

Power supply |

700W(220V/110V can be customized) |

|

Main machine weight |

55Kg |

|

Dimensions of hot press |

|

1. We supply machines with battery technology support.

2. We supply full set of lithium battery equipment for lab research, pilot scale research and production line.

|

|

|

|

|

|

|

|

|

|

|

Lab Mixer Machine |

|||

|

|

|

|

|

1 Standard exported package : Internal anticollision protection, external export wooden box package

2 Shipping by express, by air, by sea according to customer's requirements to suggest the most suitable shipping mode

3 Responsible for the damage during shipping process, change the damage part for free

4 Supply with suitable voltage input and power plug according to customer's country requirements.

5 Supply with CO, ECO, FORM A, FORM E and any other original certificate for import custom clearance and tax relief.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com