- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

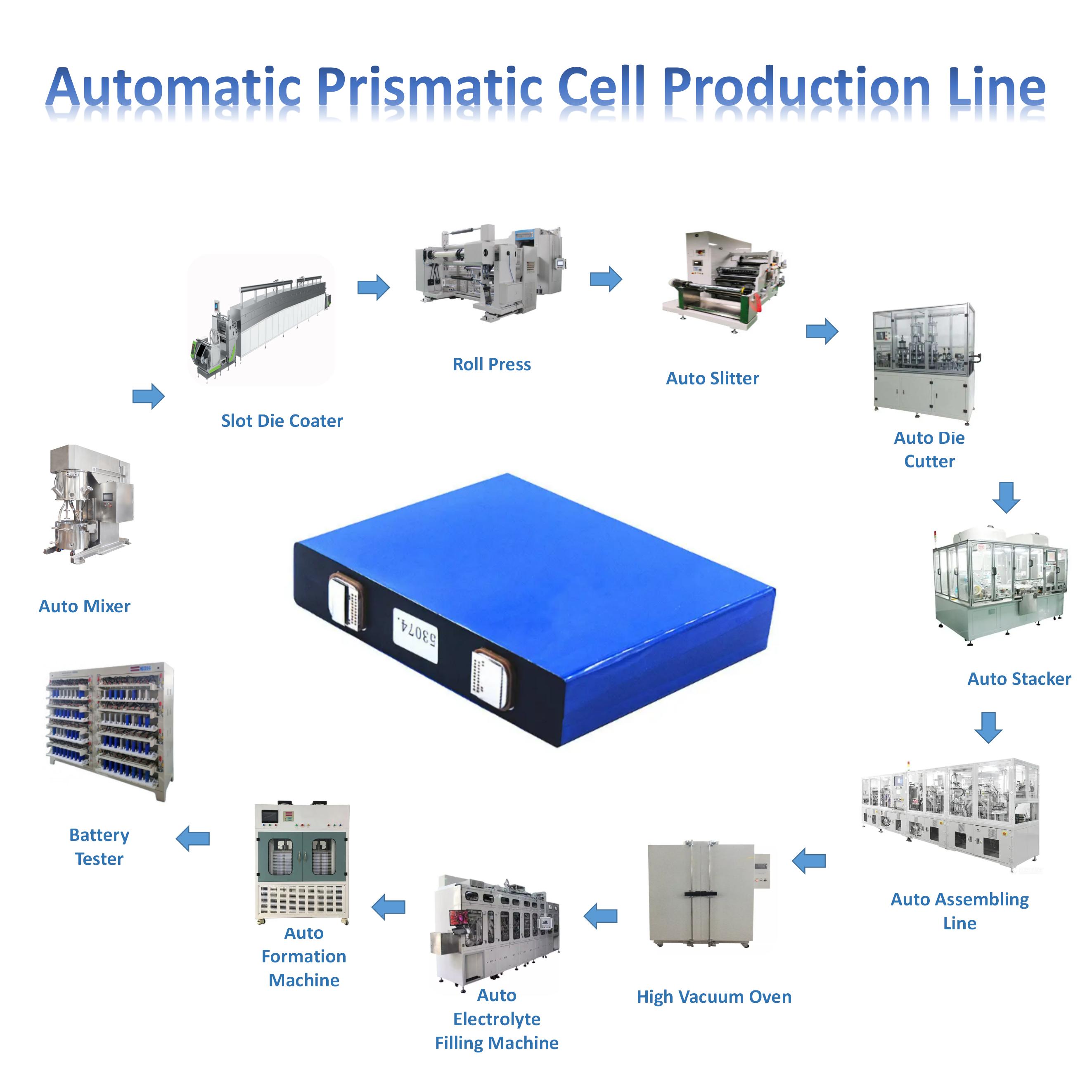

Automatic Prismatic Battery Blue Film Covering Machine

Model Number:

TMAX-YK-JABL-05Compliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Automatic Prismatic Battery Blue Film Covering Machine

1、Equipment introduction:

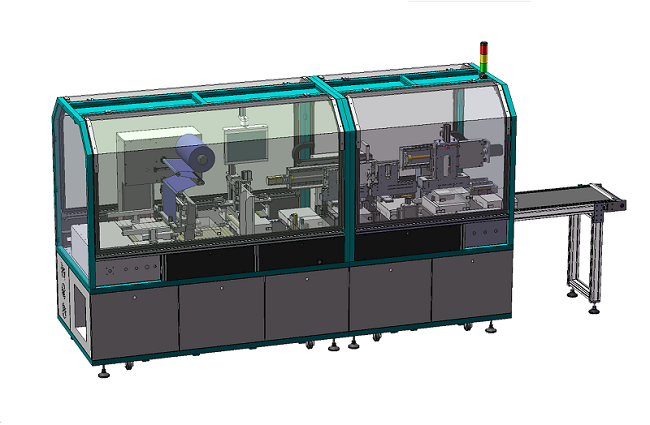

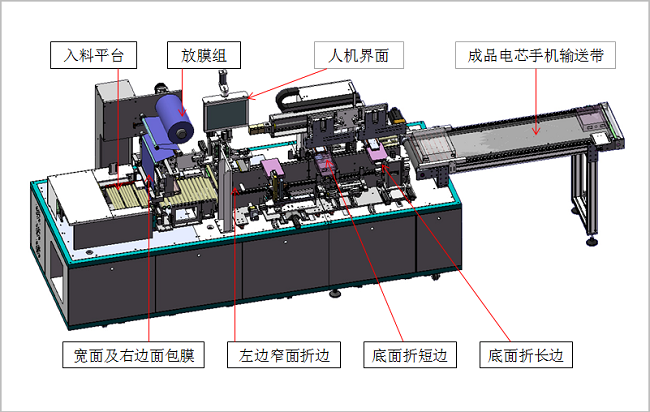

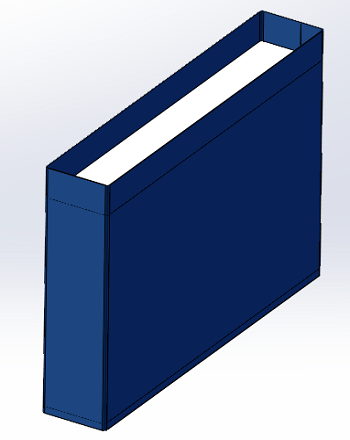

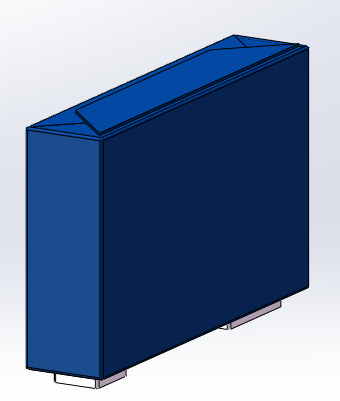

1.1Diagram of complete machine

(The outer coat of the machine adopts aluminum profile + acrylic

入料平台:Feeding platform:

放膜组:Film release group:

人机界面:interface:

成品电池输送带:Finished battery conveyor belt:

宽面及右边面包膜:Wide face and right side bread film:

左边窄面折边:Left narrow hem:

地面折短边:Ground fold short edge:

底面折长边:Bottom folded long edge:

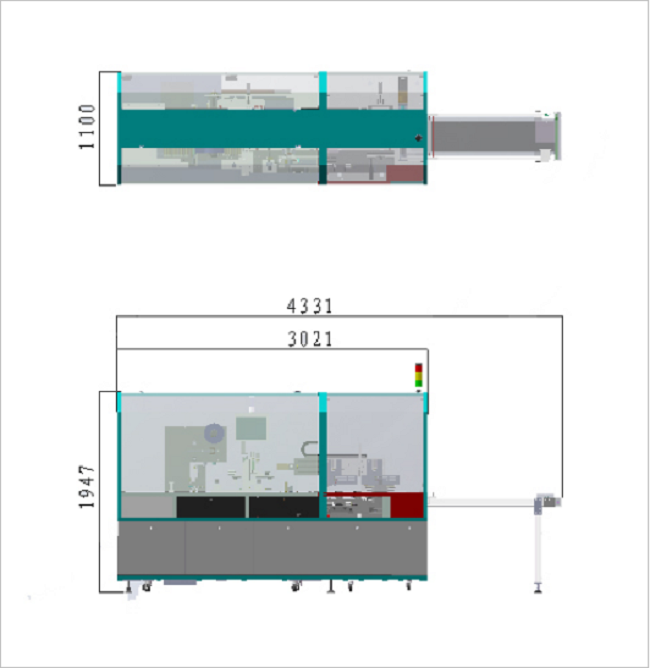

1.2 Appearance dimension

4350mm(L)× 1100mm(W)× 1950mm(H)

1.3 Equipment introduction

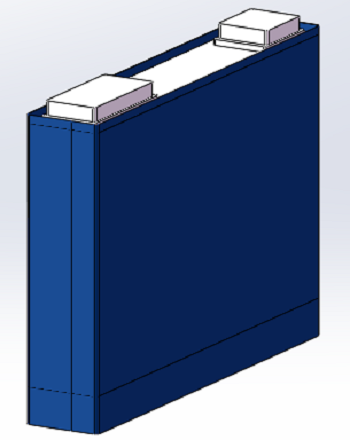

This equipment is applicable to the coating of prismatic battery cells. A layer of insulating glue is covered and pasted on the surface of the whole cell, which can better protect the cell and prevent short circuit. Manually power on the battery and collect the battery.

1.4 Principle and effect of glue coating

1.4.1The adhesive film is wrapped on all sides along the height direction of the battery and sealed on the side (as shown in Figures 1 and 2)

(Figures 1) (Figures 2)

1.4.2 The bottom of the battery is sealed in a "Y" shape, with the short side sealed first and then the long side sealed (as shown in Figure 3)

Figure 3

1.5 Process characteristics

1.5.1Size adjustable,Adjustable range:85mm~220mm(H)* 130mm~200mm(W) * 20mm~60mm(T)

1.5.2 Bubble in capsule:No wrinkle, indentation, flanging or damage; Bubble≤5mm,The number of bubbles on each front is ≤ 5, and the number of bubbles on each side is ≤ 3; Do not damage the battery or scratch the insulating film during the coating process;

1.5.3 Coating accuracy: ± 0.5mm (no blank on the battery surface); Adjustable overlap: 5mm-10mm

1.5.4 Insulate the part contacting the battery to prevent short circuit and scratch;

1.6 Incoming material

Insulating film / glue: according to customer's requirements

1.7 Institutional characteristics

1.7.1 The part in contact with the battery is designed with non-metallic materials;

1.7.2 Any part in contact with the battery has short-circuit protection, emergency stop protection, and power / gas cut-off protection function;

1.7.3 Coating action does not damage the battery;

1.7.4 The contact part with the battery is made of non-metallic materials;

1.7.5 Equipment operation status display (three color light);

1.7.6 Sufficient maintenance space shall be reserved for the whole equipment and vulnerable parts.

2、 Equipment use environment

|

Item |

Specification |

|

Power |

AC220V 50/60HZ |

|

Rated power |

3.5kw |

|

compressed air |

5kgf~7kgf/c㎡(0.5Mp-0.7Mp) Dry, anhydrous |

|

relative humidity |

20~75%HR |

|

Environmental cleanliness |

There is no corrosive gas, liquid or explosive gas on site |

|

Rated power |

3.5kw |

|

Bottom bearing |

≥500KG/m² |

3、Technical parameter

|

Item |

Specification |

|

Size |

4350mm(L)× 1100mm(W)× 1950mm(H) (the overall dimension of the equipment may be changed according to the specification of the battery) |

|

Weight |

800Kgs |

|

Rated power |

3.5kw |

|

Compress Air |

5kgf~7kgf/c㎡(0.5Mp~0.7Mp) Dry, anhydrous |

|

Efficiency |

6~8 PPM(eg:34135214) |

|

Operator |

1 |

|

Product qualification rate |

≥99.5% |

|

Equipment failure rate |

≤2% (faults caused by equipment only) |

|

Battery size |

Eg: 214mm(H)* 135mm(W) *34mm(T) Acceptable:27135206、42173166、5417345、36130130 |

4、Equipment principle and main structure

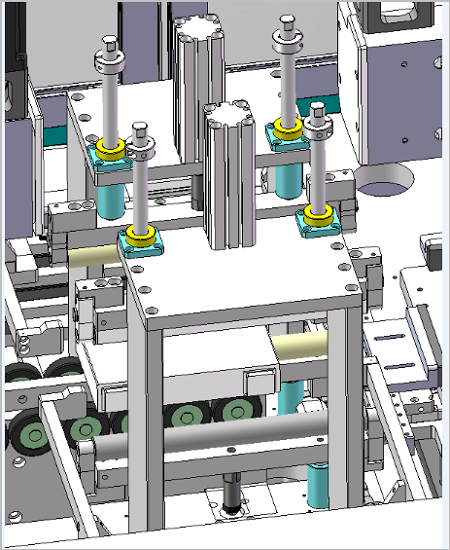

4.1 Manual feeding (Figure 4)

Manually place the cell on the feeding table, use the air cylinder to automatically correct the electric cell, and push the electric cell to the next station through the servo motor

(Figure 4)

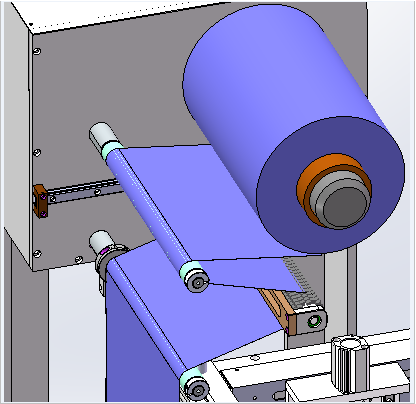

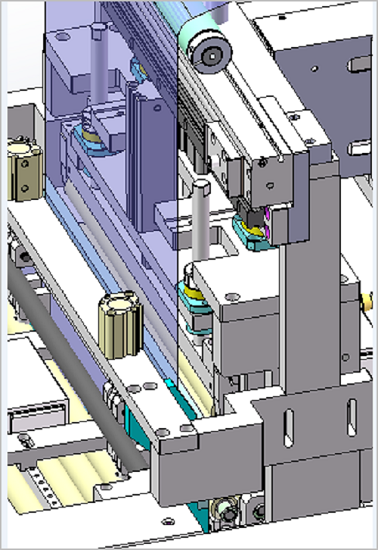

4.2 Bluing film mechanism (Figure 5)

The blue film unwinds through the tension mechanism to realize stable film unwinding

(Figure 5)

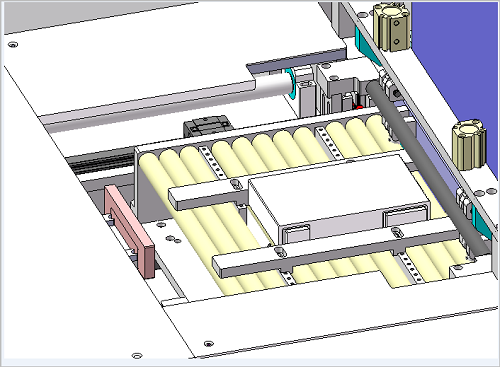

4.3 Wide and narrow bread blue film mechanism (Figure 6)

The servo push electric core is adopted, and the film drawing, coating and cutting actions are completed through the air cylinder + servo and precision mechanism to realize wide and narrow bread blue film.

(Figure 6)

4.5 Bottom hem (Figure 7)

Use the precision fixture to position the electric core, and complete the bottom folding of the electric core (excluding the top folding) in combination with the cylinder folding mechanism.

(Figure 7)

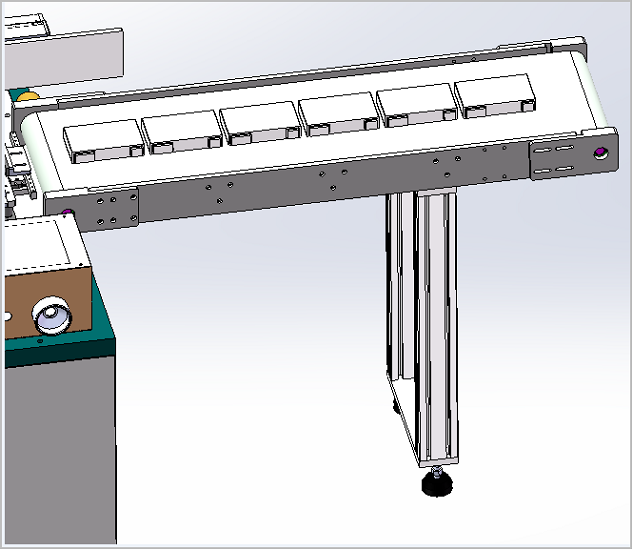

4.6 Cell collection structure (Figure 8)

Place and collect the electric cores orderly one by one through the motor drive belt.

(Figure 8)

5、Major component brands

|

SN |

Item |

Brand |

Origin |

|

1 |

servo motor |

Xinjie |

China |

|

2 |

Stepper motor |

Research control, leisai |

China |

|

3 |

PLC |

Xinjie |

China |

|

4 |

interface |

Kunlun, weiluntong |

China |

|

5 |

Air conditioning combination |

AIRTAC |

Taiwan |

|

6 |

switch |

IDEC |

Japan |

|

7 |

Siemens |

German |

|

|

8 |

Chint |

China |

|

|

9 |

SCHNEIDER |

France |

|

|

10 |

Pneumatic components |

AIRTAC |

Taiwan |

|

11 |

Flow limiting valve |

AIRTAC |

Taiwan |

|

12 |

SMC |

Japan |

|

|

13 |

Pressure relief valve |

SMC |

Japan |

|

14 |

AIRTAC |

Taiwan |

|

|

15 |

Proximity switch |

Japan |

|

|

16 |

Magnetic ring switch |

AIRTAC |

Taiwan |

|

17 |

Linear guide slider |

HIWIN |

Taiwan |

|

18 |

TBI |

Taiwan |

|

|

19 |

CSK |

Taiwan |

|

|

20 |

Ball screw |

HIWIN |

Taiwan |

|

21 |

TBI |

Taiwan |

|

|

22 |

CSK |

Taiwan |

|

|

23 |

Photoelectric switch |

Panasonic, Omron, keens |

Japan |

|

24 |

Vacuum detection |

AIRTAC |

Taiwan |

|

25 |

Bearing |

NSK |

Taiwan |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com