- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

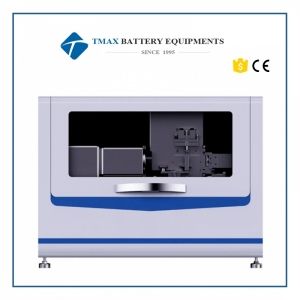

Electrolyte Wetting Testing System

Model Number:

TMAX-EWS/ETS/CHTCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

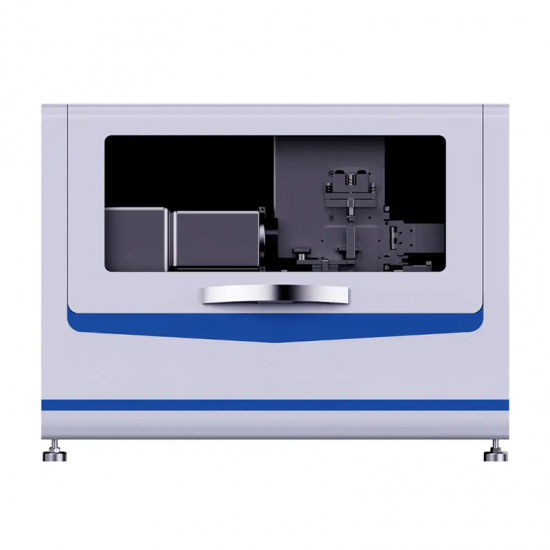

Electrolyte Wetting Testing System

Introduction

Combining the visual acquisition system and the capillary action of the electrolyte to evaluate the wetting differences of different electrodes, electrolytes, diaphragm formulations and processes.

Characteristic

1. Based on the principle of capillary diffusion of electrolyte in the electrodes and separators, quantitatively evaluate the difference in electrolyte infiltration;

2. Equipped with high-precision mechanical control and visual acquisition system, the test is stable and efficient;

3. Suitable for evaluation of infiltration differences of different electrodes, electrolytes, separator formulas and processes;

4. Characterize the infiltration rate of electrolyte in the sample in real time.

Applications

1. Electrolyte: Performance Evaluation

2. Electrode: Consistency Assessment

3. Optimization of material: Electrode Surface Treatment Processes

Description

1. Principle of Electrode Wetting

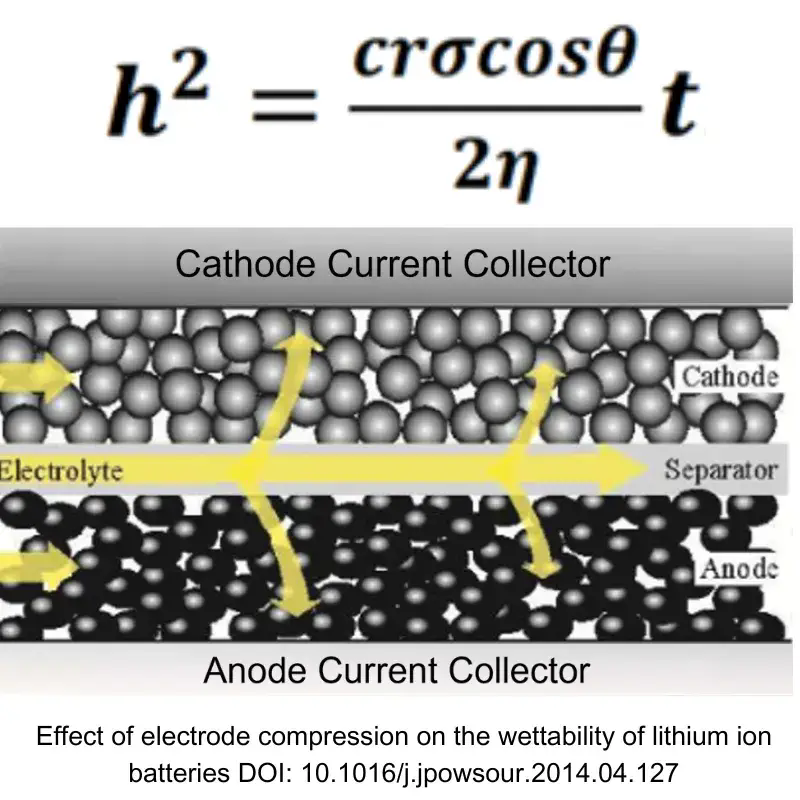

The Lucas–Washburn Equation is commonly used to describe the dynamic of liquid absorption in electrode pores, as represented by the equation below:

1) r represents the radius of the capillary (m),

2) σ represents the surface tension of the imbibition fluid (N/m),

3) η represents the viscosity of the imbibition fluid (Pa*s),

4) θ represents the contact angle of the wet phase (°),

5) h represents the liquid suction height (m),

6) t represents the liquid suction time,

7) cr represents a fixed value, called the formal radius.

2. Applications

1) Electrolyte: Performance Evaluation

2) Electrode: Consistency Assessment

3) Optimization of material: Electrode Surface Treatment Processes

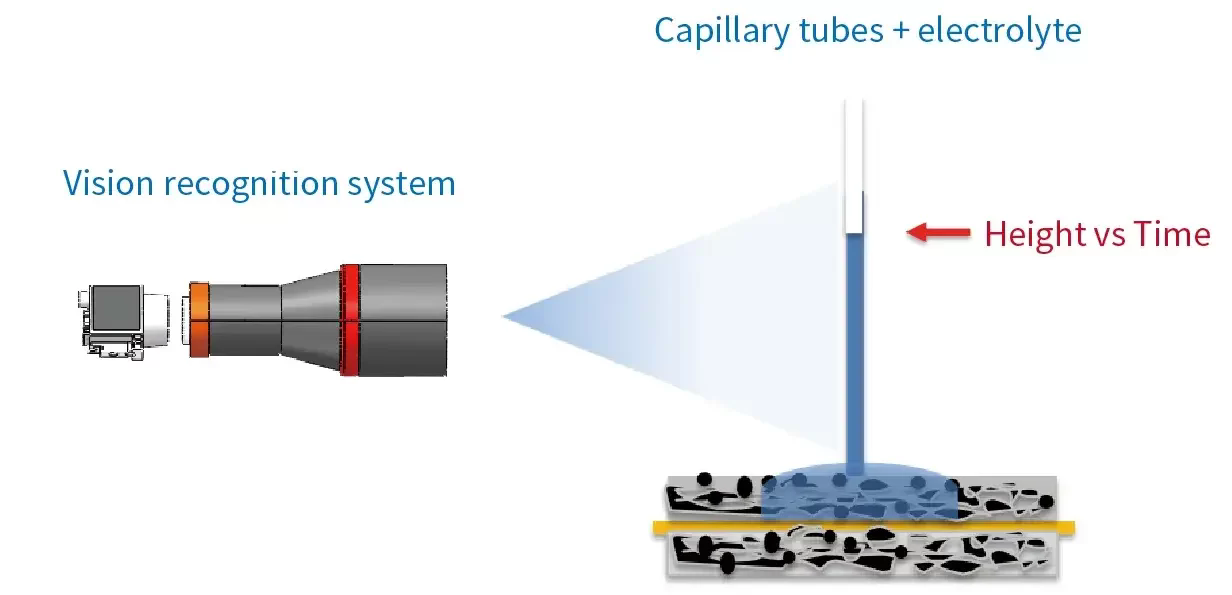

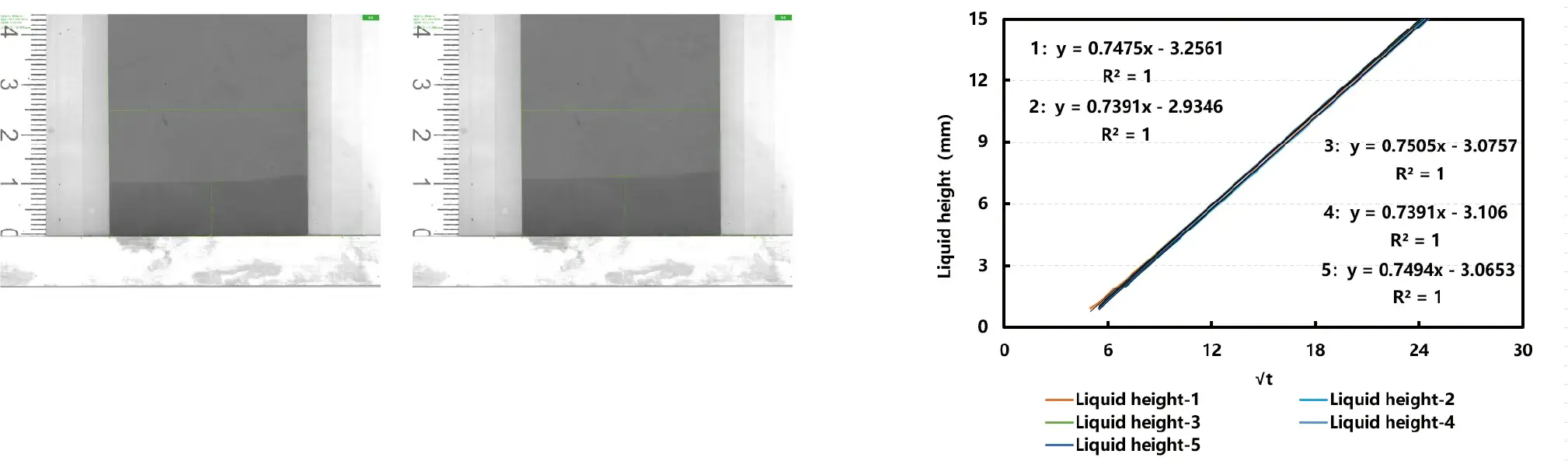

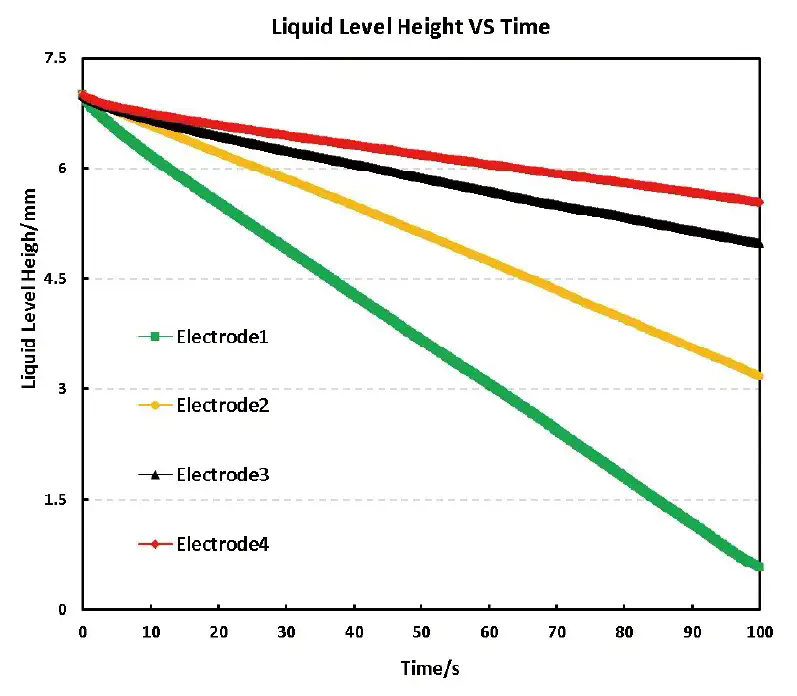

2.1 Capillary Wetting System-EWS Series

Key Features:

1) Equipped with a high-precision vision testing system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rateon negative electrode sheets of lithium-ion batteries.

3) Applicable Samples: Negative electrode sheets.

4) The greater the compacticion of the electrode sheet, the lower the porosity, resulting in poorer electrolyte wetting.

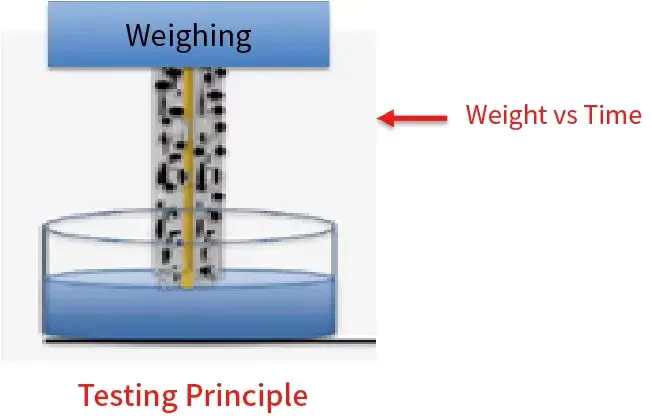

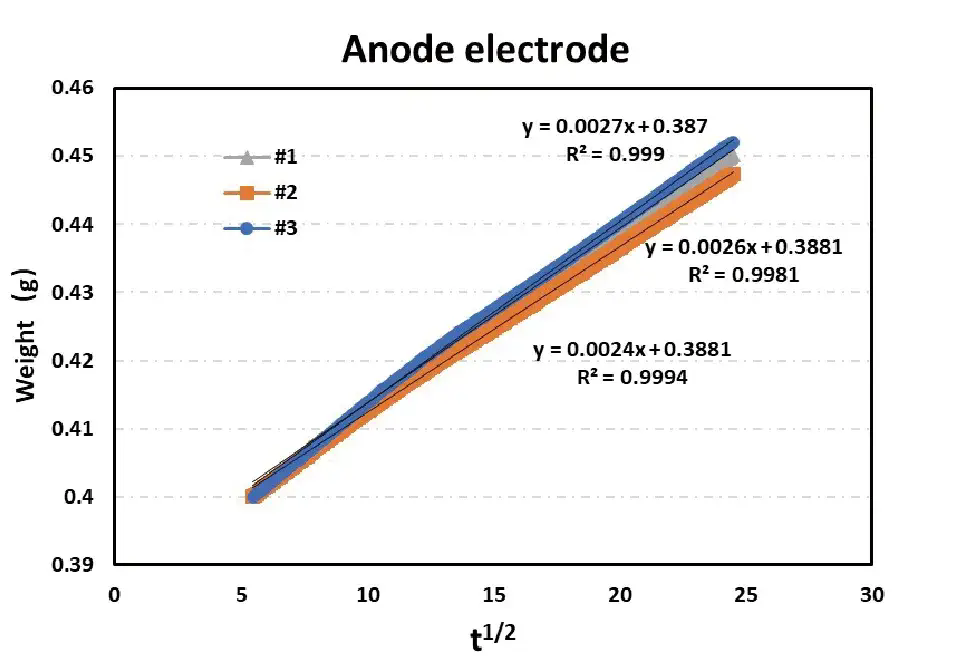

2.2 Weight Wetting System-ETS Series

Key Features:

1) Equipped with a high-precision weighing system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rate on positive and negative electrode sheets of lithium-ion batteries.

3) Applicable samples: Anode electrodes & Jelly Cells

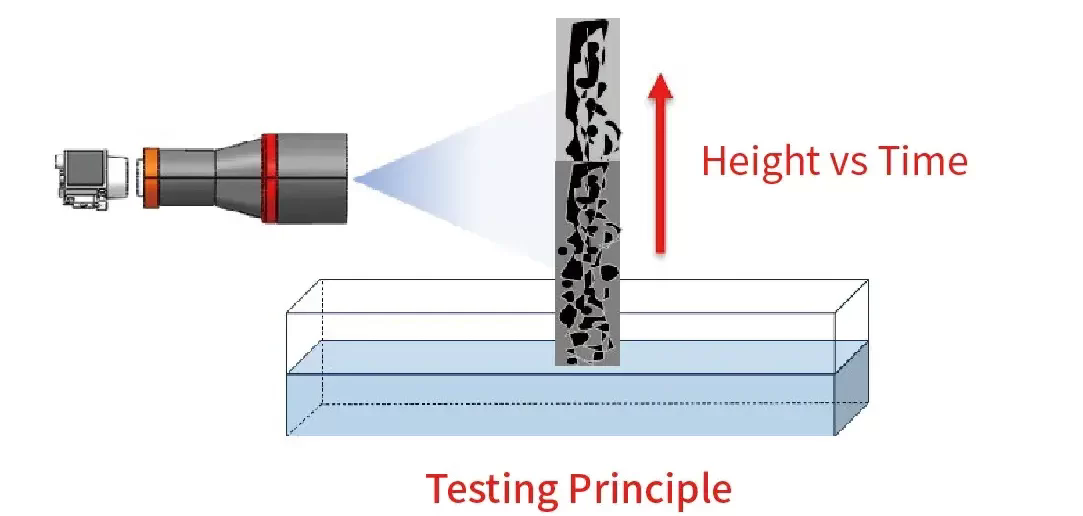

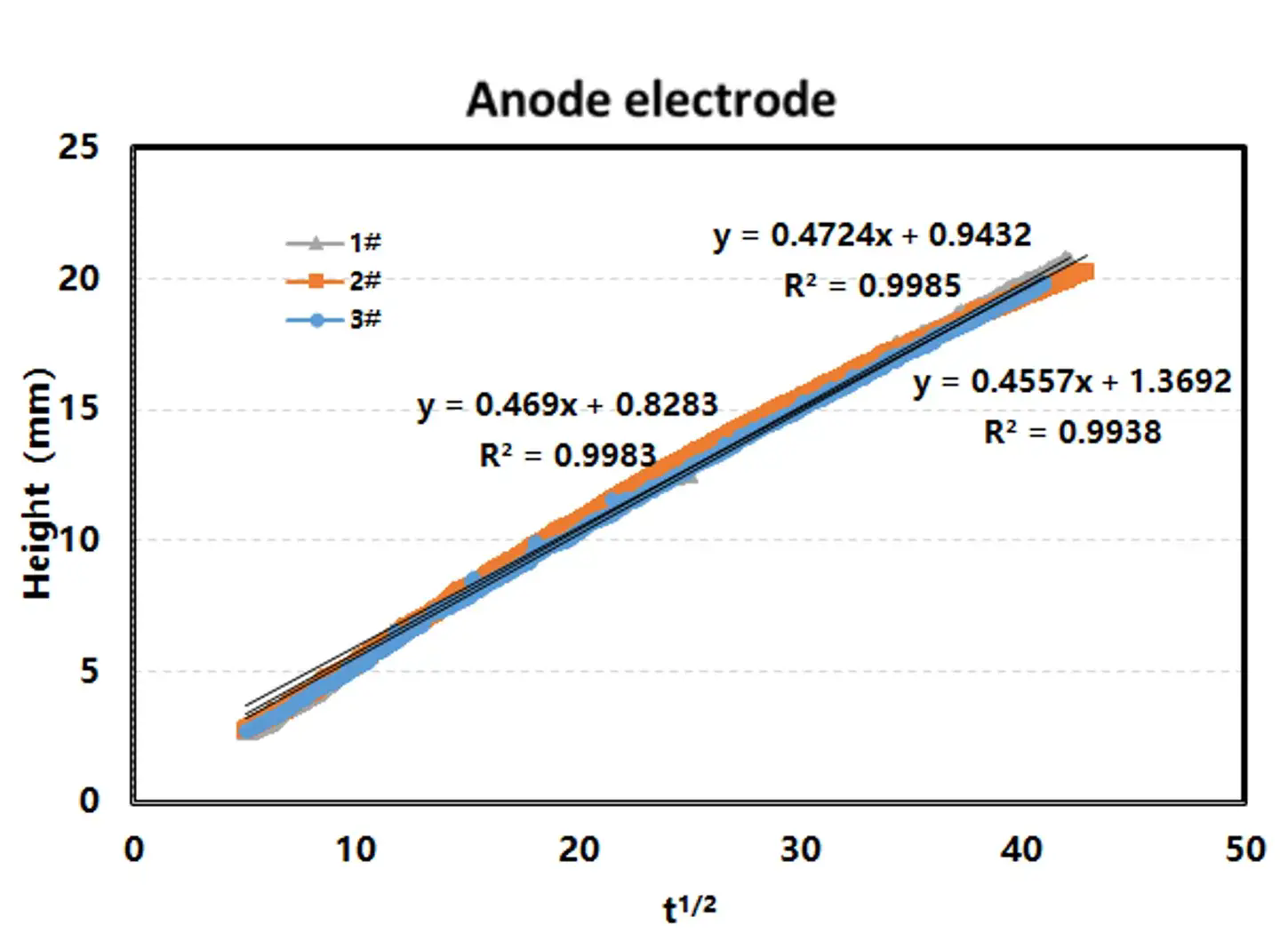

2.3. Height Wetting System-CHT Series

Key Features:

1) Equipped with a high-precision vision acquisition system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rate on positive and negative electrode sheets of lithium-ion batteries.

3) Applicable samples: Anode electrodes

Application Cases

1. Capillary Wetting System-EWS Series

The greater the density of the electrode, the lower the porosity and the worse the electrolyte wettability.

2. Weight Wetting System-ETS Series

Trimming three sets of negative electrode sheets from the same batch (65*70mm)

3. Height Wetting System-CHT Series

The slopes of the 3 tested electrodes are consistent with each other, so is the wetting consistency of their electrolytes.

Specifications

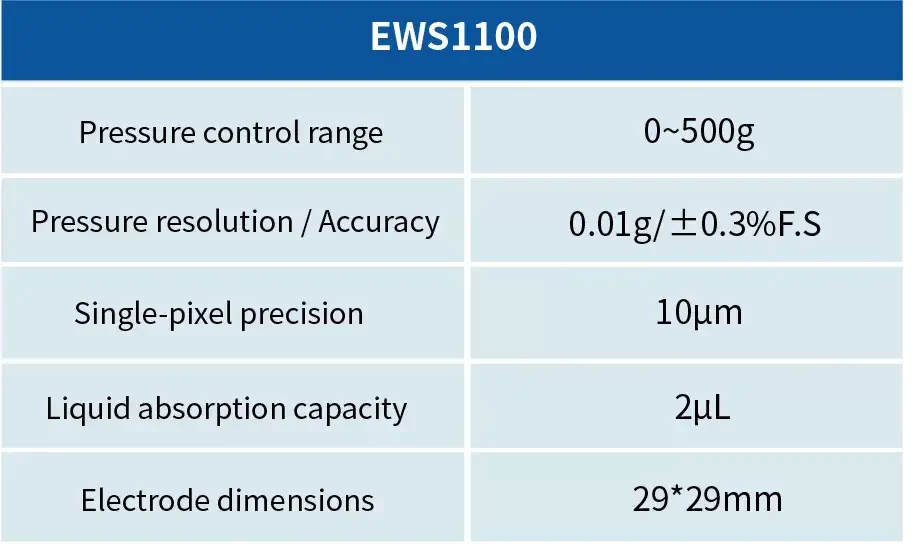

Capillary Wetting System-EWS Series

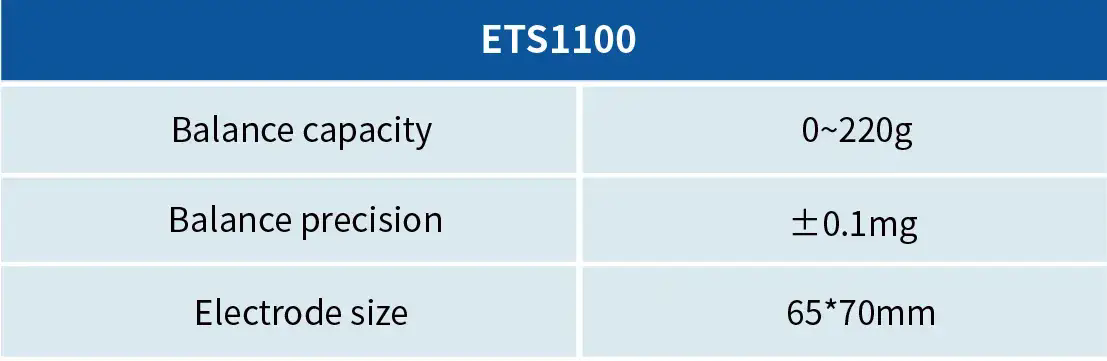

Weight Wetting System-ETS Series

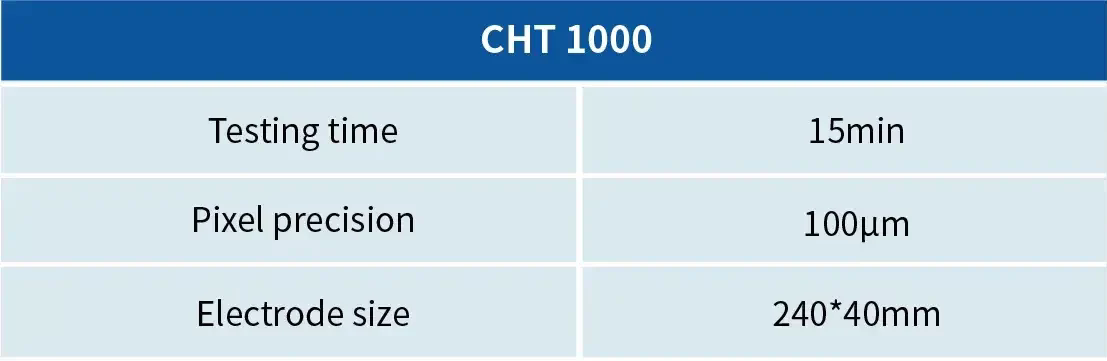

Height Wetting System-CHT Series

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com