- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

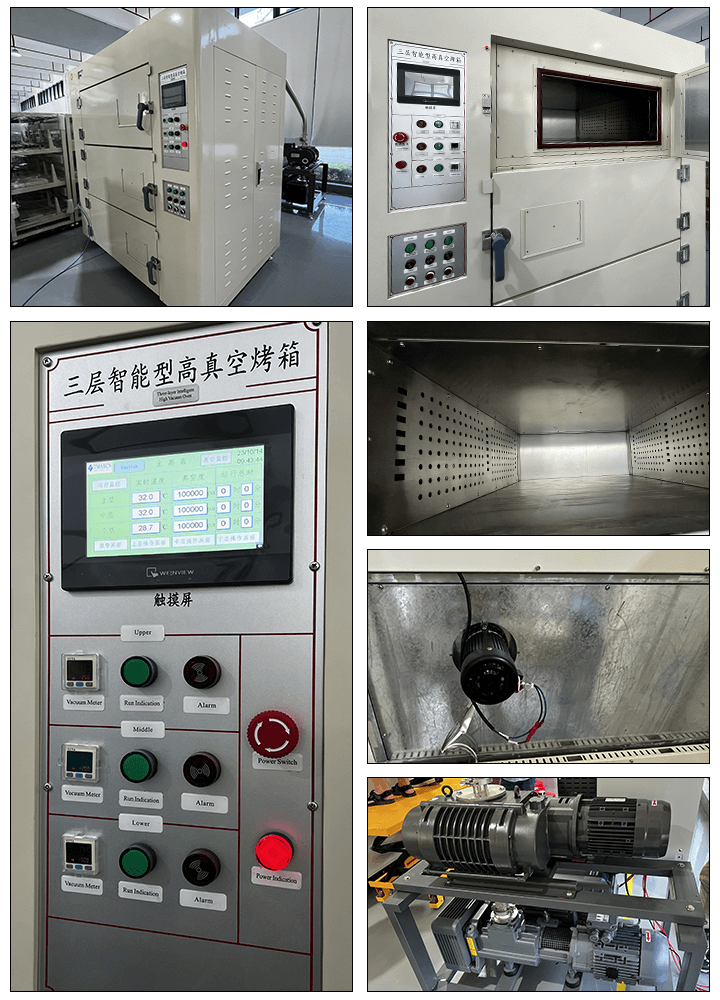

Four Drums Vacuum Drying Oven for Lithium Battery Electrode Making

Model Number:

TMAX-GZX4Compliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Four Drums Vacuum Drying Oven for Lithium Battery Electrode Making

1. Overview:

This product is specially designed for the vacuum drying process of the whole roll of electrode in the production process of lithium battery. It adopts the industry-leading uniform temperature technology, and controls the action process through the color touch screen and PLC, which is precise and reliable. It is an ideal equipment to ensure the drying effect, suitable for mass production of batteries, with good temperature uniformity, stainless steel liner, anti-corrosion, anti leakage and high quality.

2. Product features:

2.1. Select color touch screen and Xinje brand PLC to form a friendly and fast human-machine interface, which can realize automatic vacuuming, nitrogen filling, timing heat preservation, automatic shutdown and other actions or action cycles, original (Japanese) Panasonic digital display vacuum meter, 4 warehouses Independent control, independent display, no interference with each other.

2.2. The temperature control adopts Shanghai Yatai three-position PID temperature controller, which has high temperature control resolution.

2.3. The temperature measuring probe is placed at the back of the vacuum chamber, and the special model made by Taiwan Hualing is selected to quickly and truly reflect the working temperature.

2.4. Triple over-temperature protection device, each independently senses the temperature, and automatically cuts off the heating when the set temperature is exceeded, ensuring the safety of materials and equipment.

2.5. Each layer of air conveying fans can be turned on independently, and the blower can be turned on separately when the pole pieces are cooled to quickly cool down.

2.6. The use of high-quality 304 stainless steel seamless electric heating tube, heating up quickly, energy-saving and durable, life can reach 10-15 years.

2.7. Cylindrical cavity design, built-in circular shaft core ¢60 can suspend the entire roll of pole pieces, the shaft core can bear a maximum load of 380KG.

2.8. Adopt surrounding hot air to heat the vacuum chamber, and circular air duct to ensure high-precision and uniform temperature in the chamber.

2.9. The inner cavity material is T4.0mm high-quality SUS 8K mirror stainless steel, which is resistant to corrosion of battery slurry and electrolyte.

2.10. Multi-layer thermal insulation materials form a closed thermal insulation layer to prevent the loss of thermal insulation and effectively solve the problems of adjacent warehouse string temperature and outer wall heating.

2.11. The box door is a double-layer tempered glass structure with over-pressure protection function. When the air pressure in the cavity is too high, it can automatically deflate to restore the air pressure in the cavity to the allowable range.

2.12. A special high-temperature resistant silicone sealing ring is equipped between the vacuum chamber and the door, and the -0.098Mpa state in the chamber can be maintained for more than 24 hours.

3. Technical parameters

|

Item |

Spec |

|

touch screen |

7.0 inch color touch screen |

|

PLC |

Xinjie programmable controller |

|

thermostat |

Shanghai Yatai PID temperature controller |

|

vacuum meter |

Panasonic (Japan) digital vacuum meter |

|

Operation interface |

Color touch screen + PID temperature controller + digital vacuum meter; can realize automatic ventilation, constant temperature, cooling and other actions |

|

Studio size |

Inner cavity size (single bin): Φ 550mm (diameter) × 600mm (depth); |

|

Overall dimensions |

Height 1850mm × width 2380mm × depth 1200mm |

|

power |

Single layer 6kW (peak power) × 4 |

|

Power Supply |

Three phase 380V |

|

Matching gas source |

Vacuum: -0.095~-0.1Mpa Compressed air: 0.4~0.5Mpa Dry gas: 0.1~0.2Mpa |

|

working temperature |

Room temperature~150℃ |

|

Temp Accuracy |

±1℃ |

|

Uniformity of temperature distribution |

The temperature difference of each point in the working room≤±2℃ |

|

heating rate |

It takes about 25 minutes for room temperature (calculated at about 25°C) to rise to 80°C |

|

Heating mode |

Electric heating, surrounded by hot air circulation, independent of each layer |

|

Over temperature protection device |

Each layer is equipped with dual mechanical over-temperature protection, independent temperature measurement |

|

Alarm mode |

Alarm light + buzzer on |

|

Vacuum degree of working room |

0~-0.098Mpa, the vacuum degree will keep ≥96% after keeping the pressure for 24 hours |

|

Pressure transition rate |

Working room vacuum and inflatable vacuum breaking time is less than 1 minute |

|

Studio materials |

SUS stainless steel plate |

|

Shell material |

Using SECC steel plate, surface spraying plastic, |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com