- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

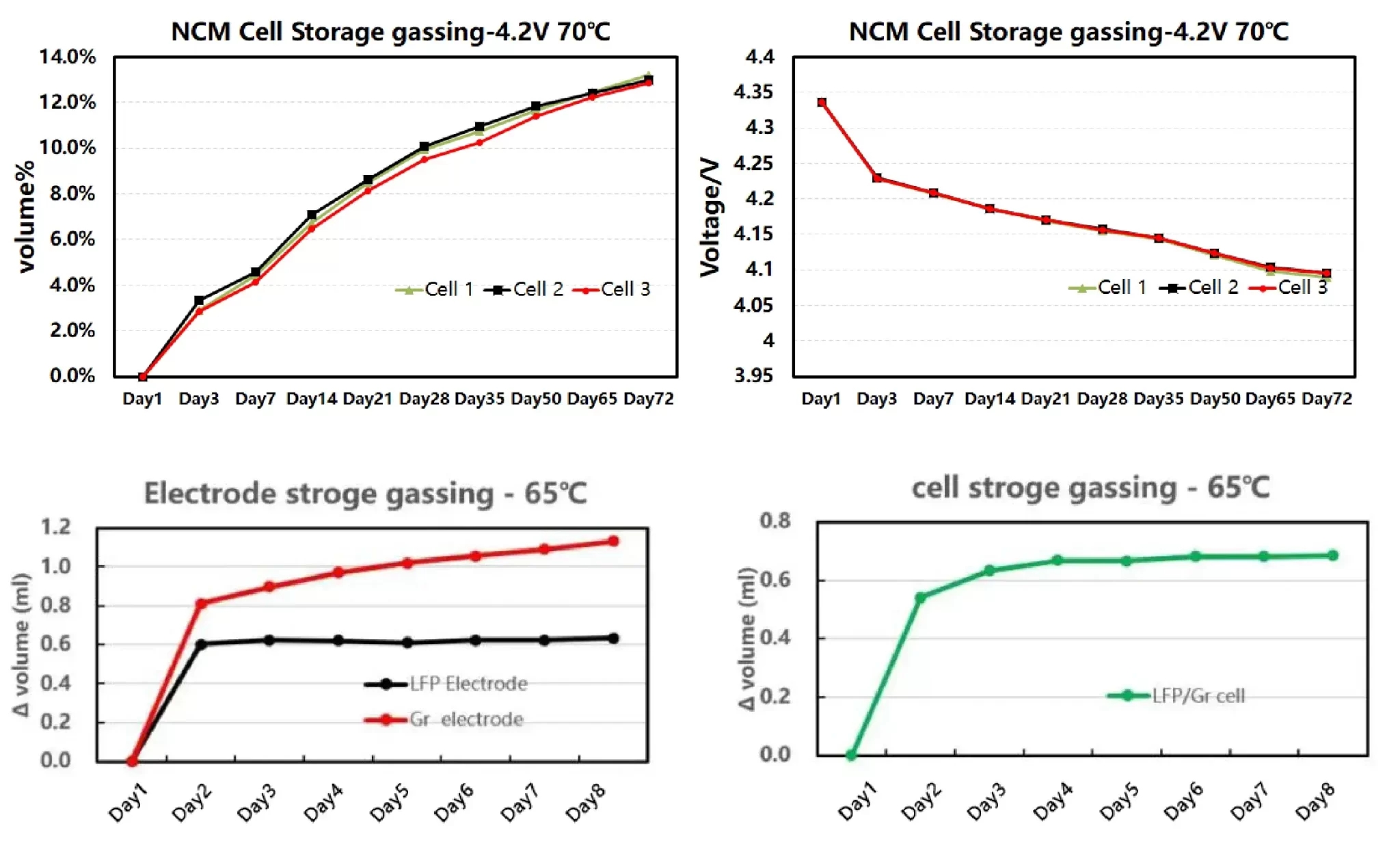

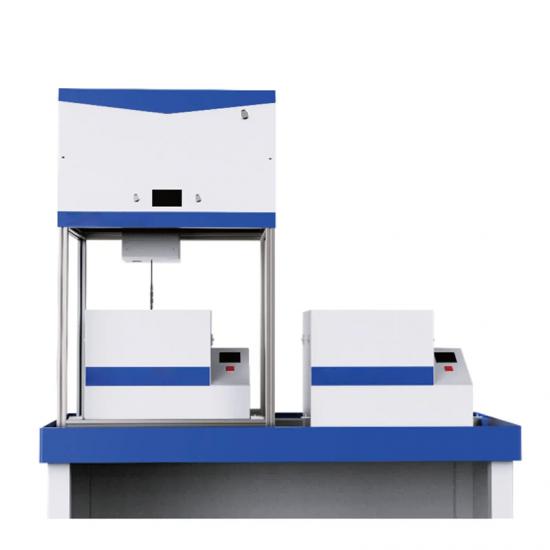

In-Situ Multi-Channel Battery Storage Gassing System

Model Number:

TMAX-MSG2000Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

In-Situ Multi-Channel Battery Storage Gassing System

Characteristic

1. In-situ Storage Gassing testing for pouch cells

2. Multi-channel Testing (up to 64 channels)

3. Automatical Data Recording(volume, voltage and internal resistance)

4. Access to External Cyclers

Description

1. Disadvantages:

1) The temperature changes duringthe process result in gas generation and testing losses.

2) Manual data recording may introduce errors, as data collection must be done manually.

Traditional – Oven & Balance Method

TMAX In-Situ Storage Method

Equipment Setup

Requires multiple devices: oven, voltmeter, balance, charging/discharging equipment

Integrated equipment

Equipment Functions

Temperature change, volume, voltage

Temperature change, volume, voltage, supplementary power

Volume Measurement Precision

Low precision, > 50μL

High precision, < 30μL

Operation Mode

Complicated, requires transferring cells multiple times

Simple, in-situ measurement, no transfer needed

Data Recording

Manual multiple recordings

Software automatic recording

| Traditional – Oven & Balance Method | TMAX In-Situ Storage Method | |

|

Equipment Setup |

Requires multiple devices: oven, voltmeter, balance, charging/discharging equipment | Integrated equipment |

|

Equipment Functions |

Temperature change, volume, voltage |

Temperature change, volume, voltage, supplementary power |

|

Volume Measurement Precision |

Low precision, > 50μL |

High precision, < 30μL |

|

Operation Mode |

Complicated, requires transferring cells multiple times |

Simple, in-situ measurement, no transfer needed |

| Data Recording | Manual multiple recordings |

Software automatic recording |

2. Features

2) Multi-channel Testing (up to 64 channels);

3) Automatical Data Recording(volume, voltage and internal resistance);

4) Access to External Cyclers.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com