- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

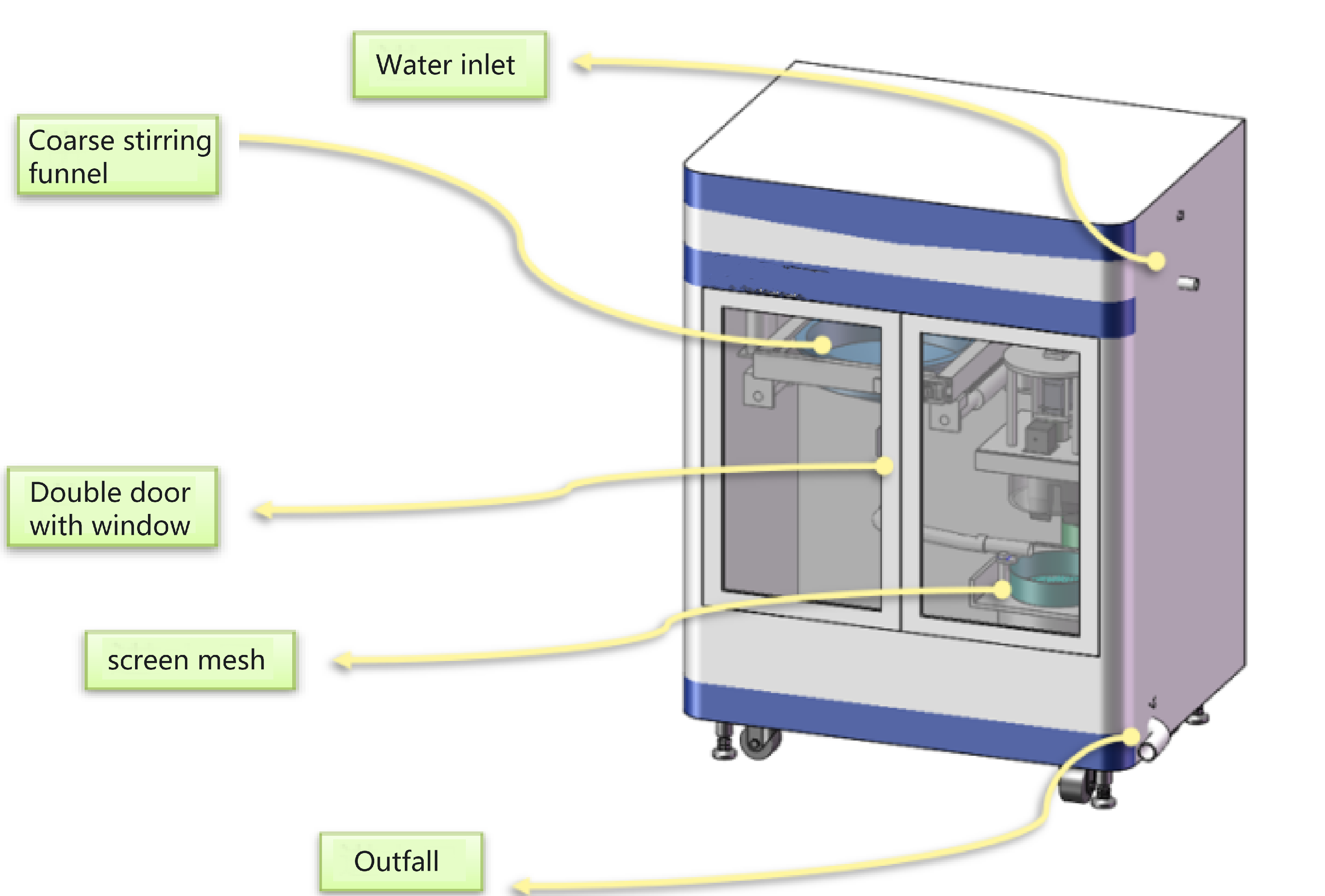

Lab Automatic Powder Wet Vibrating Screen System Device With Non-Metallic Structure Screening Part

Model Number:

TMAX-WVS1000Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Lab Automatic Powder Wet Vibrating Screen System Device With Non-Metallic Structure Screening Part

Introduction

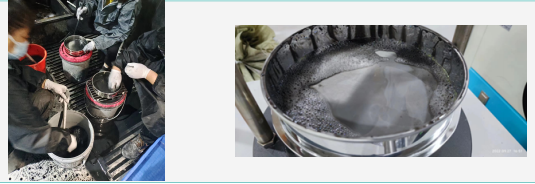

Background: manual screening and mixing method with wooden stick are adopted.. At least two people are required to operate at the same time, and 3-4 people are required when the quantity of incoming materials is large;

Problem points: poor operating environment, waste of manpower, low efficiency, introduction of manual methods,and poor consistency.

Creative Solutions

Advantages

1. Operation automation: realize the automation of powder screening process;

2. Manpower reduction:it can reduce the manpower to only one operator

3. Consistency improvement: it can reduce the differences in personnel skills and improve the consistency level;

4. Efficiency improvement: shorten testing time;

5. Convenient cleaning: all adopt quick-release and quick-change structure;

6. The screening part is of non-metallic structure: it can avoid the interference of metallic particles

Equipment parameters

|

Items |

Parameter |

|

Mixing drum |

10kg |

|

Level sensor tolerance |

±3mm |

|

Amplitude or speed |

0.2-3mm |

|

Screenable diameter |

1200 mesh, 0.014mm (the screen can be replaced as required) |

|

Screening mode |

Wet sieve |

Installation requirements

|

Items |

Parameter |

|

Equipment voltage |

380V |

|

Number of power interfaces |

1 |

|

Water source interface/number of interfaces |

Deionized water/2 |

|

Size |

1000*1000*1500mm |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com