- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

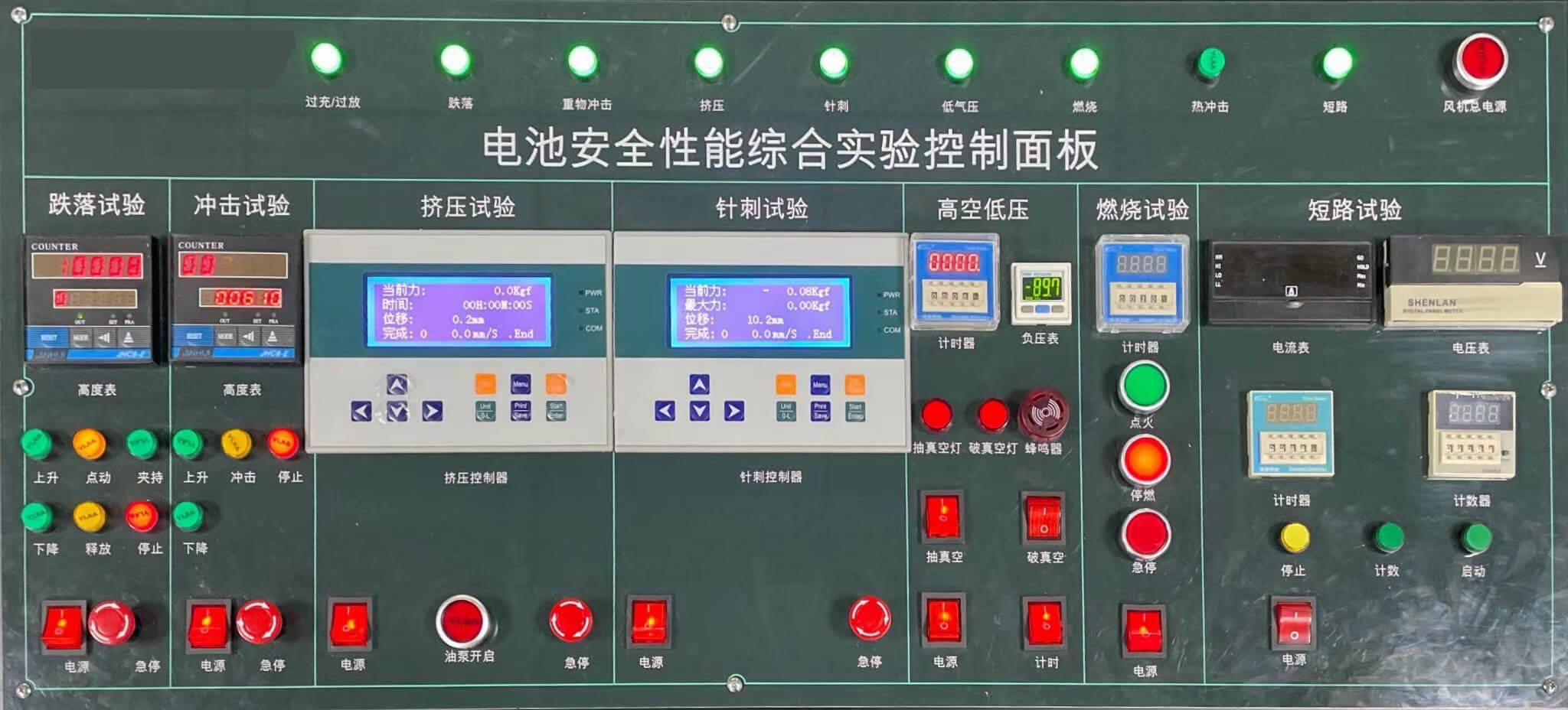

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Laboratory Battery Drop Tester Machine For Lithium Battery Safety Testing

Model Number:

TMAX-6001Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Laboratory Battery Drop Tester Machine For Lithium Battery Safety Testing

Introduction

This machine is suitable for mobile phones (cell phones), cell phone lithium batteries, walkie-talkies, electronic dictionaries, building intercom phones, CD/MD/MP3, and other small consumer electronic products and parts for free fall tests.

Features

*This machine adopts a pneumatic structure, the test piece is placed in a special fixture (adjustable stroke) and clamped firmly, press the drop button, the cylinder is released, and the test piece will be tested in a free fall;

*Encoder display height, intelligent control (0~1500 adjustable, very convenient for customers to use);

*The front door of the test box adopts a strengthened design. The left side of the door is equipped with an exposed hinge, and the right side is equipped with a powerful door lock, which effectively blocks the door. The hinge and lock use strengthened equipment special standard parts.

*The bottom is equipped with 4 casters, which is convenient to move and fix.

*This machine adopts PID digital display control system, which is convenient and intuitive, and can easily control each input test parameter.

Technical parameter

|

Drop height |

300-2000mm |

|

Display accuracy |

0.1mm |

|

Height error |

±5mm |

|

Display method |

PID display test parameters |

|

Allowable maximum weight of test sample |

2kg±100g |

|

Allowable maximum size of test sample |

L300*W320 |

|

Falling to the floor medium |

Steel plate (1 piece each for cement board and hardwood board) |

|

Test drop point |

Free fall |

|

Drop method |

Pneumatic drop |

|

Lifting method |

Electric lifting |

|

Use air pressure |

<2mpa (air source prepared by customer) |

|

Dimension |

W650*D520*H1700 |

|

Power supply |

AC 220V ± 10%, 50Hz |

|

Power |

60W |

|

Weight |

About 75kg |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com