- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

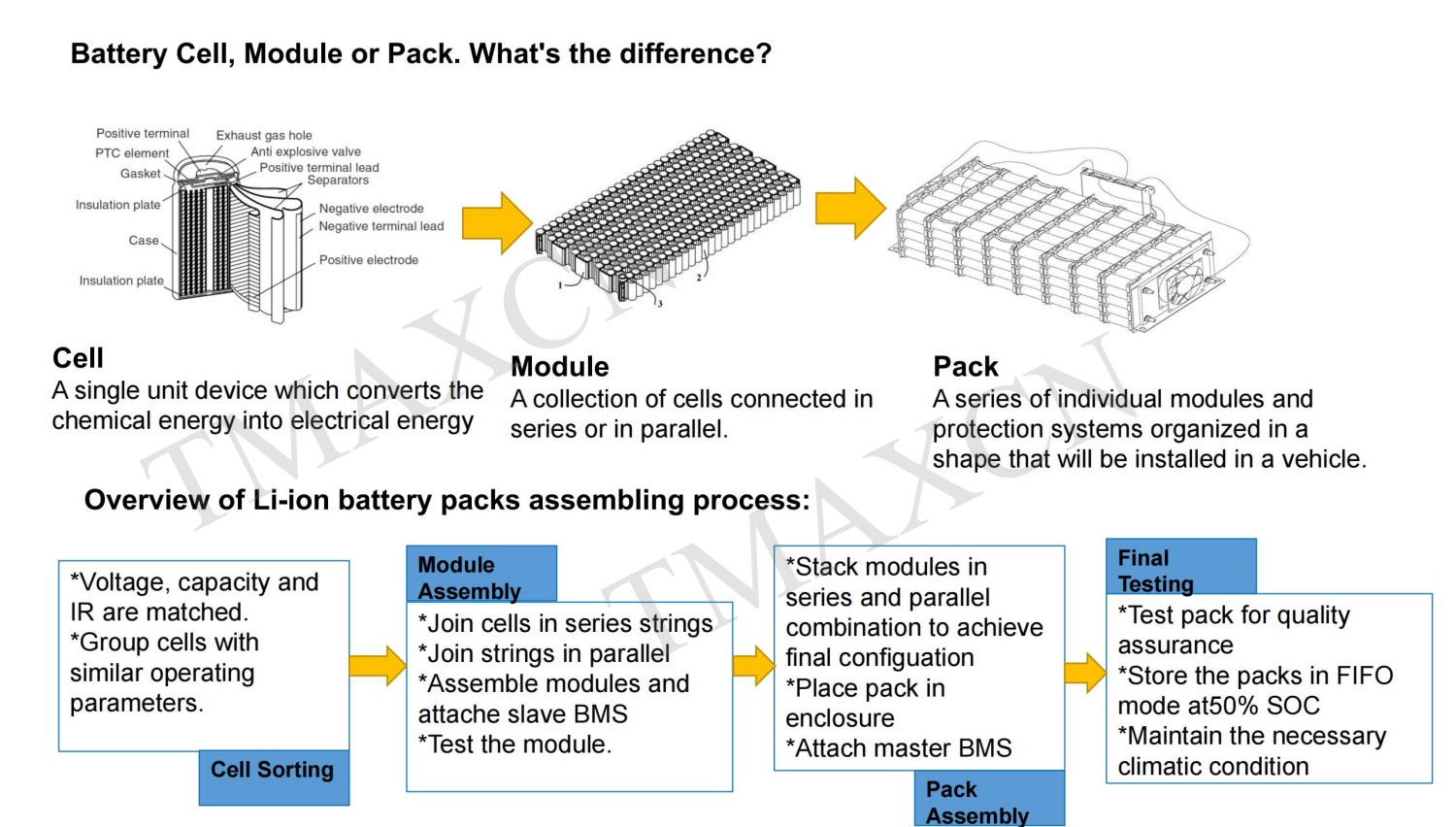

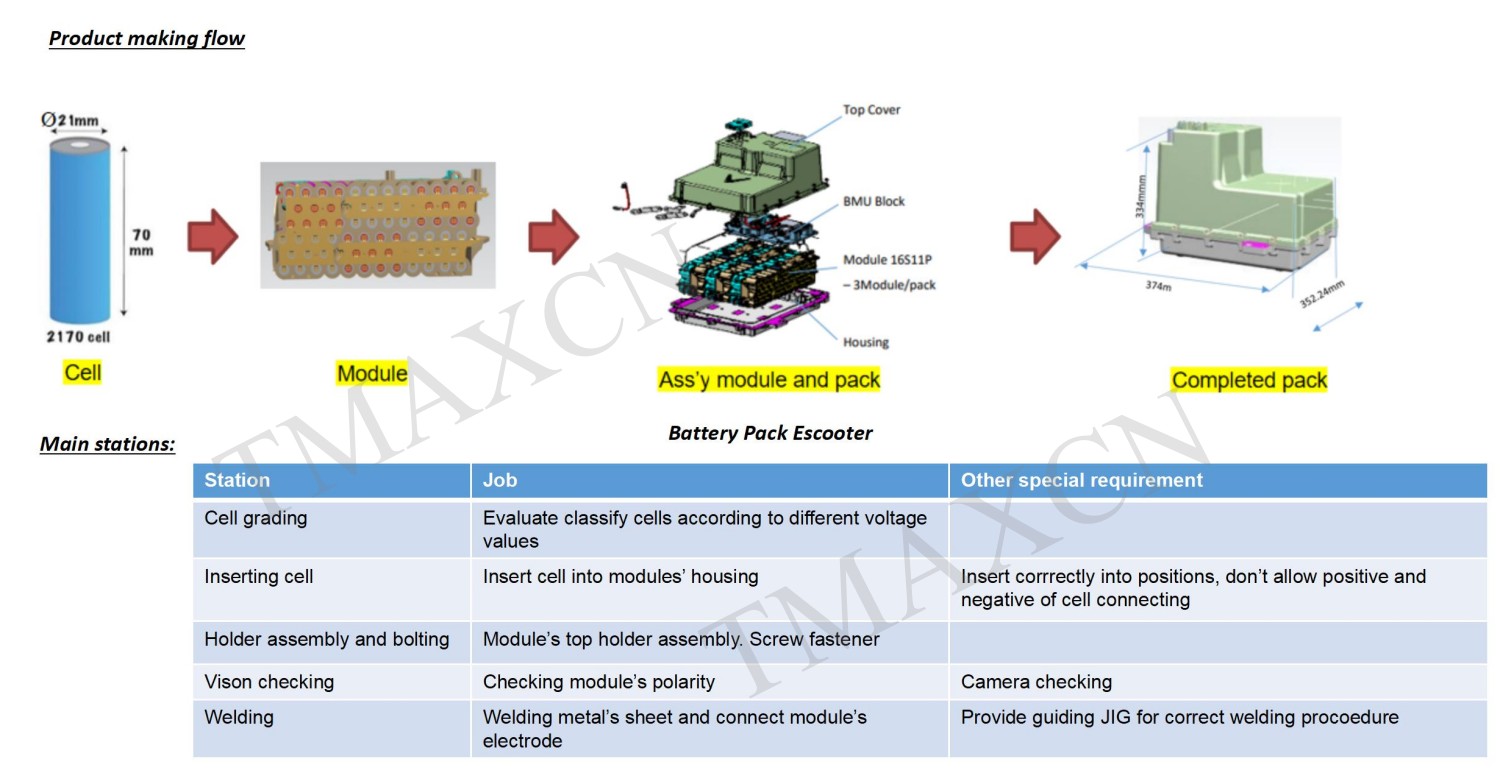

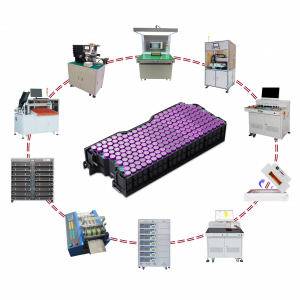

Lithium-Ion Cylindrical Battery Pack Assembling Line

Model Number:

TMAX-LFPCompliance:

CE CertifiedWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western Union

Lithium-Ion Cylindrical Battery Pack Assembling Line

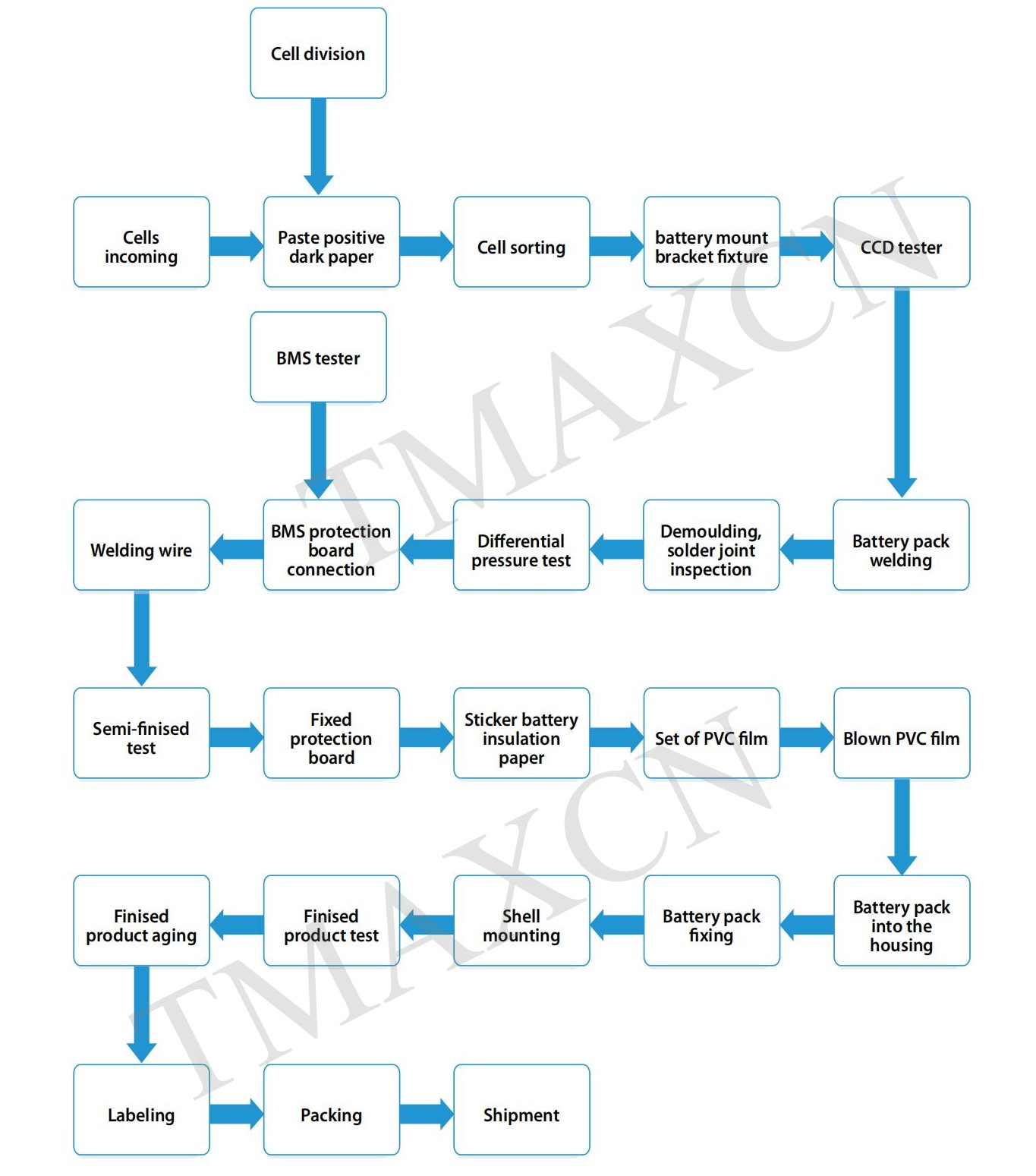

Detailed flowchart for Li-ion battery pack assembling with Cylindrical cells

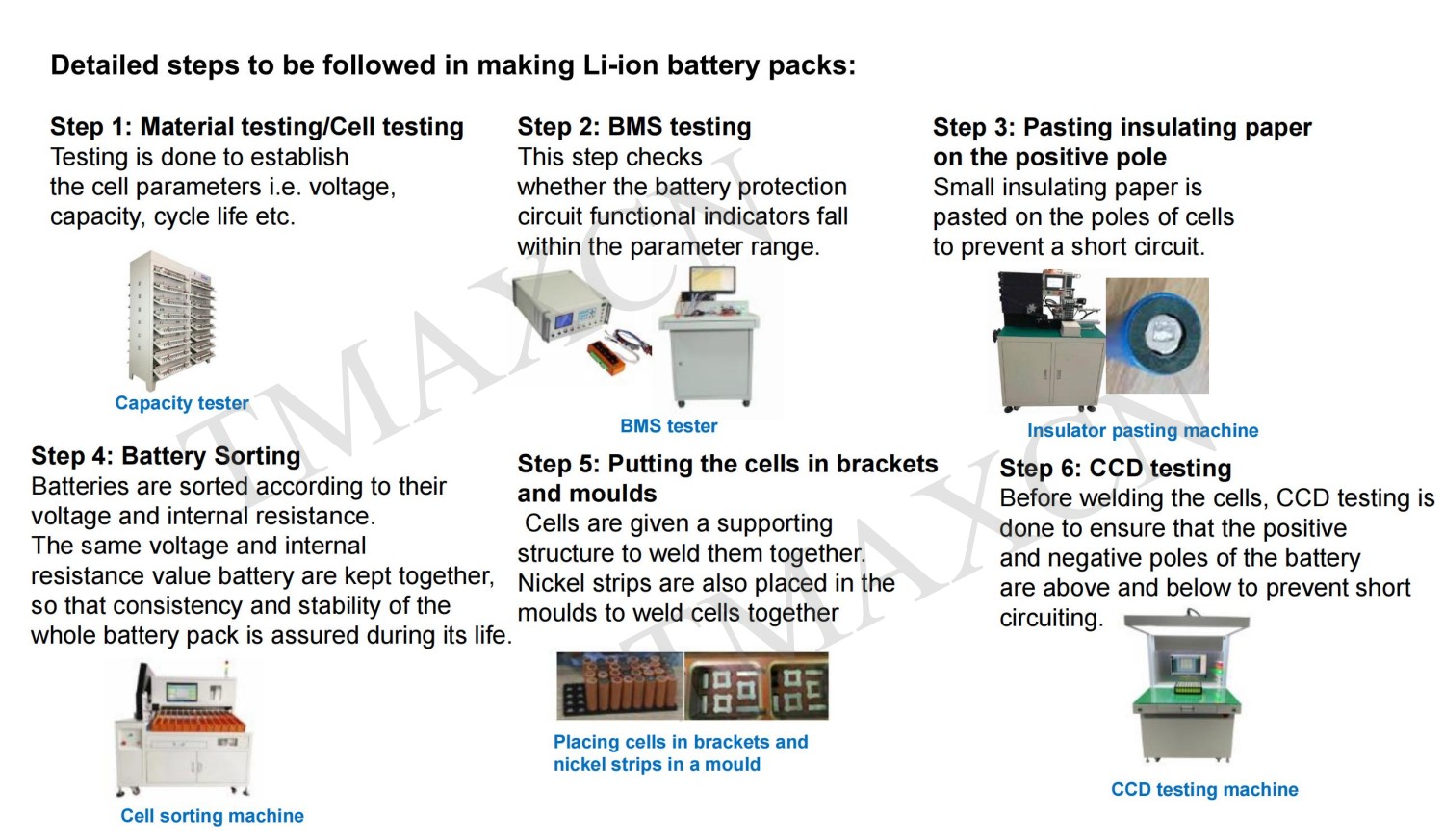

Important process:

1. Detection of single cell:

Battery Tester is mainly used to detect whether the parameters such as cell capacity, magnification and cycle times meet the use requirements.

2.Paper sticking

The positive electrode of the battery is pasted with insulating highland barley paper to protect the battery.

3.IR&Voltage Sorting

The lithium battery sorter can be set to multiple gears through the upper and lower limits of internal resistance. The resistance is adjustable, and the adjustment mode is diversified and fast. It is equipped with imported voltage internal resistance tester, integrated PC, high-end drive, all electric motor configuration; Process detection signal comprehensive and bid farewell to a single industrial machine.

4.Battery Polarity Detection

It has higher efficiency and accuracy in detecting whether the batteries are correctly placed in series-parallel positive and negative electrodes and in detecting products with defects in spot welding.

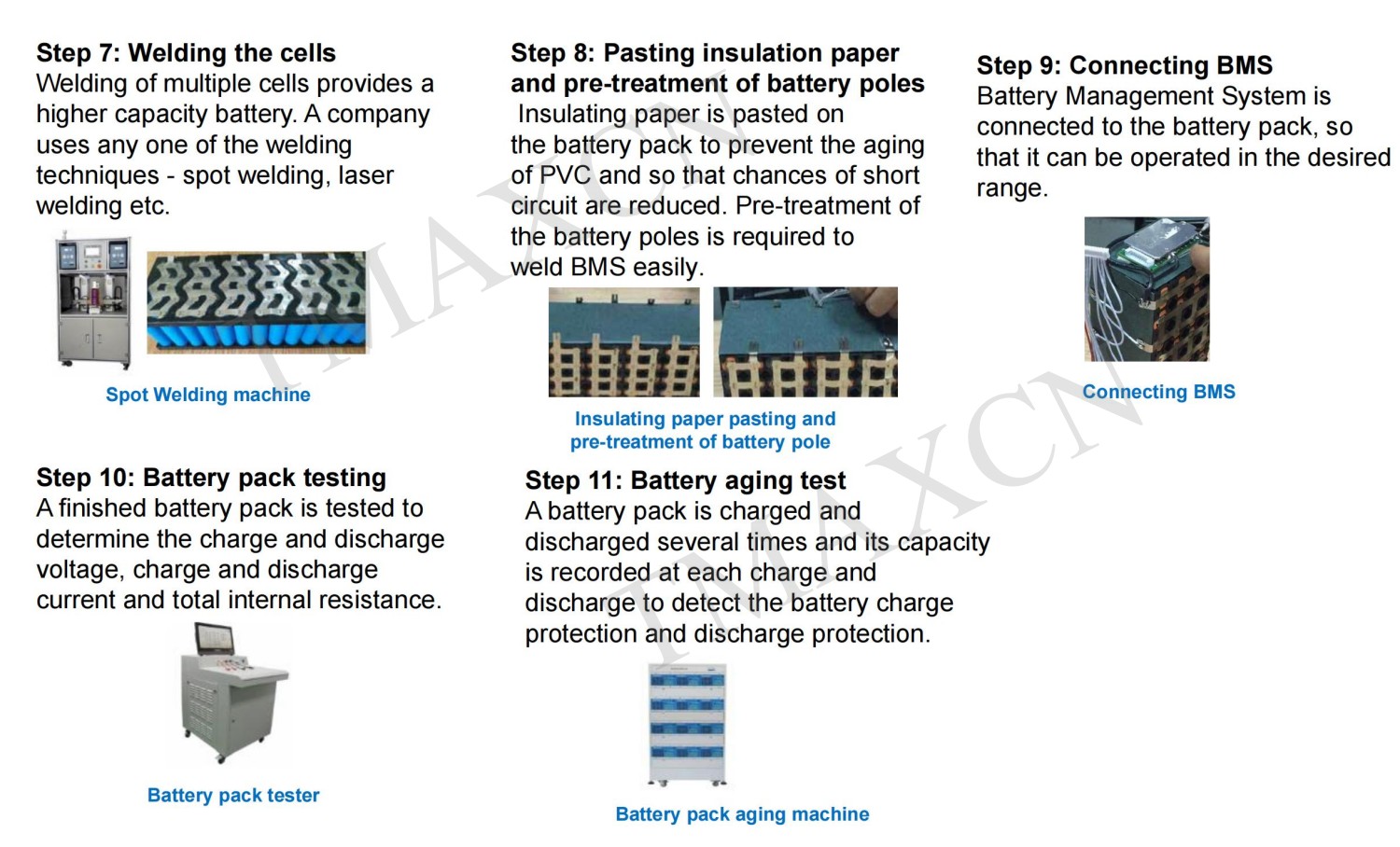

5.Spot Welding

This equipment is mainly used for welding the battery and nickel strip in the cylindrical battery assembly. The welding pulse width is adjustable, the welding spatter is small, and the welding spot is not discolored. It has the function of two-stage current detection and comparison, sound and light alarm for abnormal current, effectively preventing the occurrence of false welding and false welding. It has the function of fault self diagnosis, displaying the corresponding fault points and facilitating maintenance.

6. BMS Testing

The multifunctional protection board tester is mainly used to test whether the functional indexes of the power battery protection board are within the parameter range, so as to provide a set of testing standards for the staff.

7.Comprehensive Function Testing

Battery Pack Comprehensive Function Tester:

The main test items include: open circuit voltage, AC internal resistance, discharge test, discharge over-current test, short circuit protection test, charging test and charging protection test.

8.PVC Heat Shrinking

PVC Heat Shrinking Machine is used for shriking the PVC of battery pack.

9.Code Printing

It Is For Code Printing On The Battery Pack.

10. Charging&Discharging

The aging cabinet is mainly used for testing the charging and discharging cycle of finished lithium batteries.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com