- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

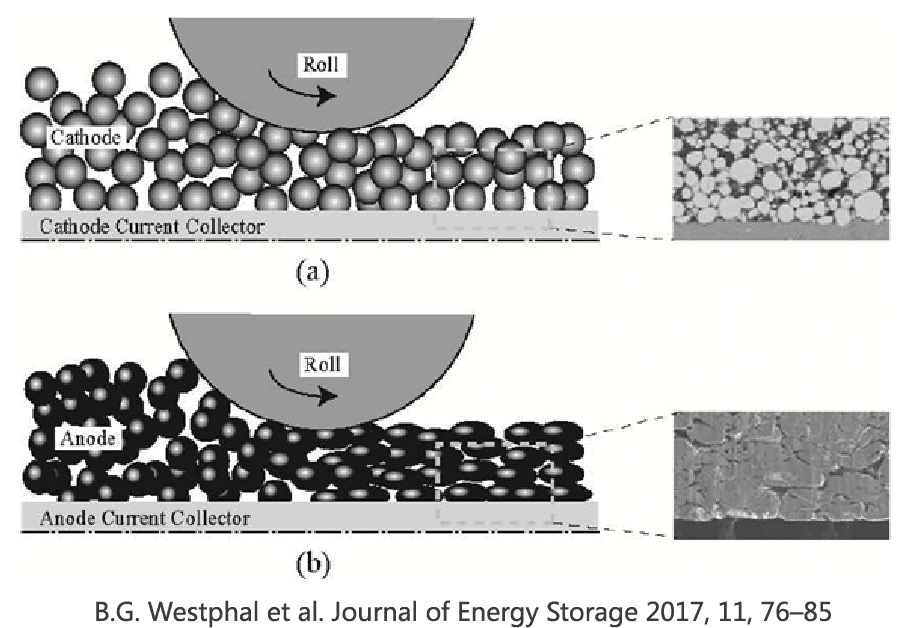

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

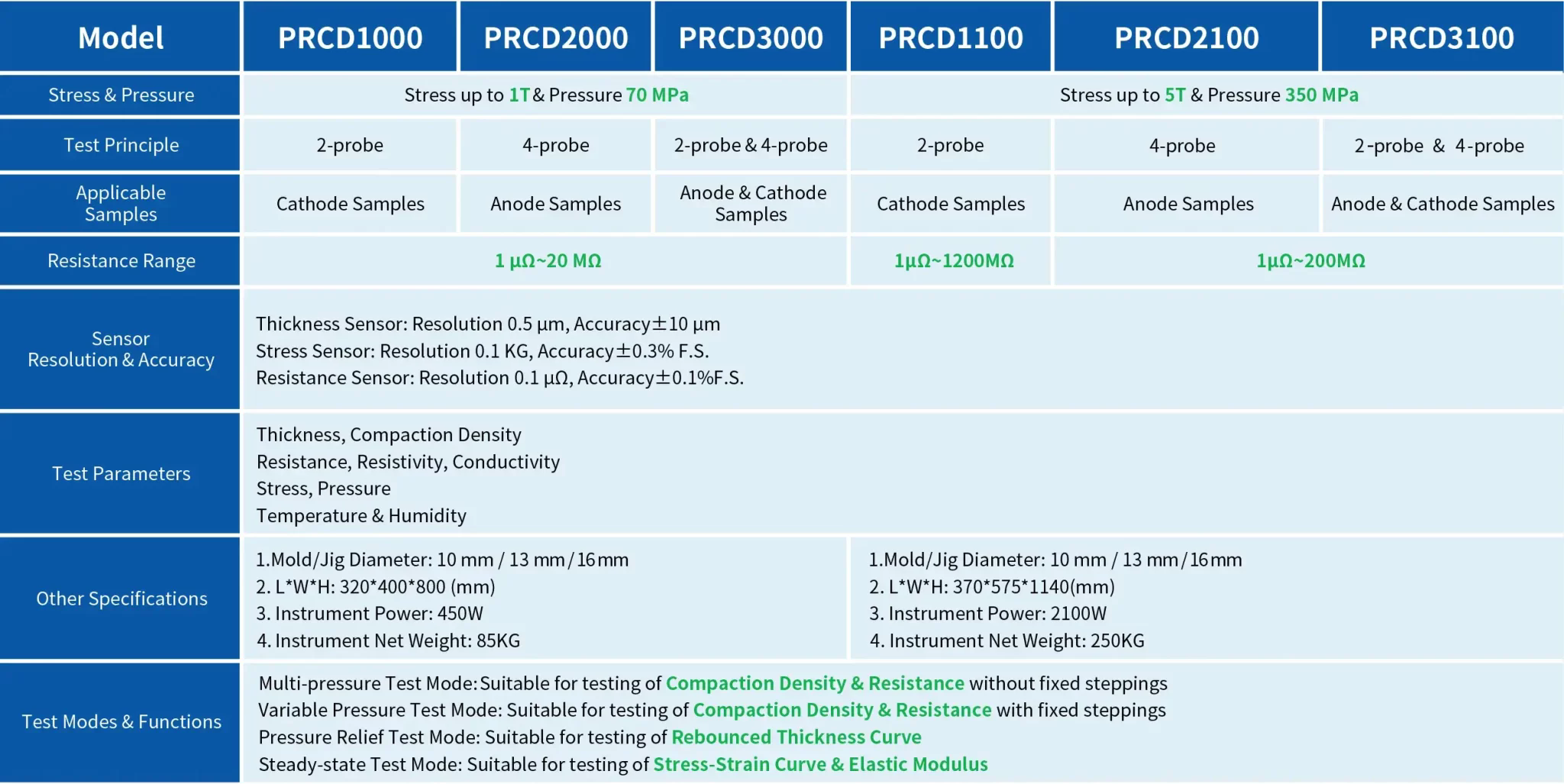

Powder Resistivity & Compaction Density Measurement System

Model Number:

TMAX-PRCD3100Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Powder Resistivity & Compaction Density Measurement System

Introduction

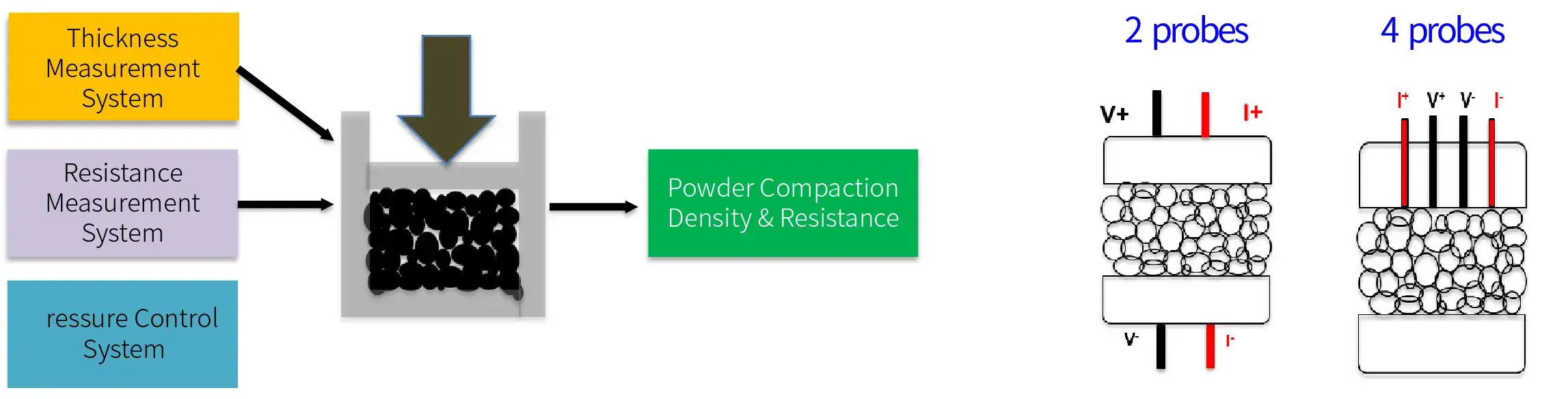

TMAX-PRCD3100 combined with high-precision pressure control,thickness and resistance testing system, free choice of four-probe and two-probe method. Accurately test the resistivity and compaction density of powders for material research and development and batch stability monitoring of powder materials.

Performance

1. Ultra-wide pressurization range (maximum 350MPa) and ultra-wide resistance measurement range (200MΩ);

2. When measuring resistance, two-probe and four-probe dual principles can be switched freely;

3. Fully automatic test software, free parameter setting, one-click start;

4. Real-time monitoring and output of pressure, pressure, ambient temperature, ambient humidity, thickness, resistance, resistivity, conductivity, compaction density and other parameter curves, and automatic saving of test data.

5. Multiple powder test modes: pressurization, single-point pressure relief, steady-state pressure relief;

6. Equipped with standard thickness blocks and resistance blocks calibrated by a third-party metrology institute.

Application

1. Lithium (sodium) positive and negative electrode powders (LCO/NCM/LFP/Graphite, etc.).

2. Conductive agents.

3. Solid electrolyte powders.

4. Other micron-sized powder materials, etc.

Description

1. The Significance of Powder Resistance

The rate performance of lithium-ion batteries(LIBs) is closely relatedto the battery resistance. The battery resistance includes ionic resis-tance and electronic resistance. The ionic resistance mainly refers tothe resistance of lithium ions in the electrolyte in the electrodepores, the resistance of lithium ions through the solid electrolyte interphase(SEl),the chargetransfer resistance of the lithium ions and electrons at the interfaceof the active material/SEl , and the solid diffusion resistance of thelithium ions in the active material. The electronic resistance mainlyrefers to the resistance of the positive and negative active materialsthe current collector resistance, the contact resistance between theactive materials, the contact resistance between the active materialand the collector, and the welding resistance of tabs. in the practical production process of LIBs, the ionic resistance partneeds to be evaluated by using the finished product. However,the electronic resistance part can be quickly evaluated byusing the materials and electrodes. Therefore, the accurate evaluation of the electronic resistance of the materials andelectrodes is of great significance for predicting the resistance of the LIBs.

2. Instrument Principles

Measurement range:

* Pressure: up to 350MPa

* Resistance: 1μΩ~200MΩ

3. Test Parameters

Stress, pressure, thickness, compaction density, resistance, resistivity, conductivity.

4. Test Methods

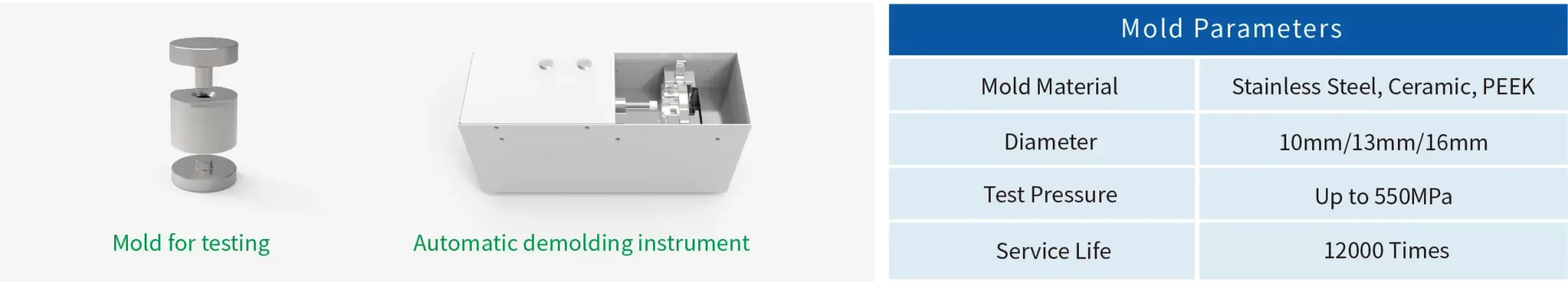

Put a certain amount of powder (1~2g) into the mold and vibrate it, then put the mold into the testing chamber and start the testing of thickness and resistance changes during the compression process.

5.Why Compaction Density instead of Tapped Density?

Result Analysis

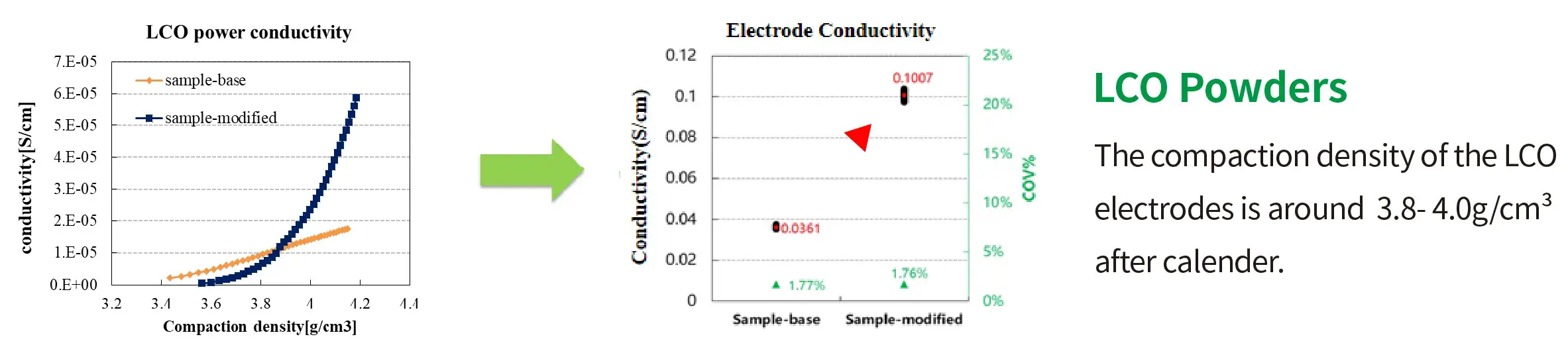

Using LCO powder as an example, when the compaction density ofthe modified powder sample is less thar3.87g/cm’ (pressure <75MPa), its conductivity is lower than that of the unmodified powder sample.However, when the compaction density exceeds 3.87g/cm’ (pressure>75MPa),the conductivity ofthe modified powder beeinsto surpass that of the unmodified powder, and the conductivity improves significantly as the compaction increases

Conclusion: When testing the conductivity of powder, the compaction density should be close to the actual compaction oithe powder in the electrode.

6. Features

1) High accuracy pressure system : Driven by servo motor.

2) High accuracy displacement sensor : Precisely measure the variation of thickness.

3) Specific clamp for resistivity & Compact density test of powder samples : Simplify the process of the powder loading and cleaning.

4) Multi-functions : One-stop data collection of key parameters of pressure, resistance, thickness, temperature and humidity with high reliability, to provide a complete traceability for each result.

5) Automatic measurement : Providing flexible measurement modes for different kinds of samples, and all the process parameter setting are integrated into a simple software control interface, with one-button to start a measurement

6) Integrated design :Integration of control and measurement systems for pressure, resistivity and thickness control and measurement systems.

7. TMAX MS Software

1) Pressure can be set willfully within the extent of max pressure.

2) The resistivity under different pressure can be measured in succession with controllable rate and interval of pressure scan.

3) Different data analysis curves can be generated, including resistivity-pressure curve, resistivity-thickness curve, Compact density-pressure curve, and pressure-thickness curve.

4) Two resistance data collection modes: interval time mode or automatic steady state condition determine mode.

5) Data statistical analysis functions.

6) Automatic generation of reports with the value of resistivity (or conductivity) and Compact density.

8. Applictions

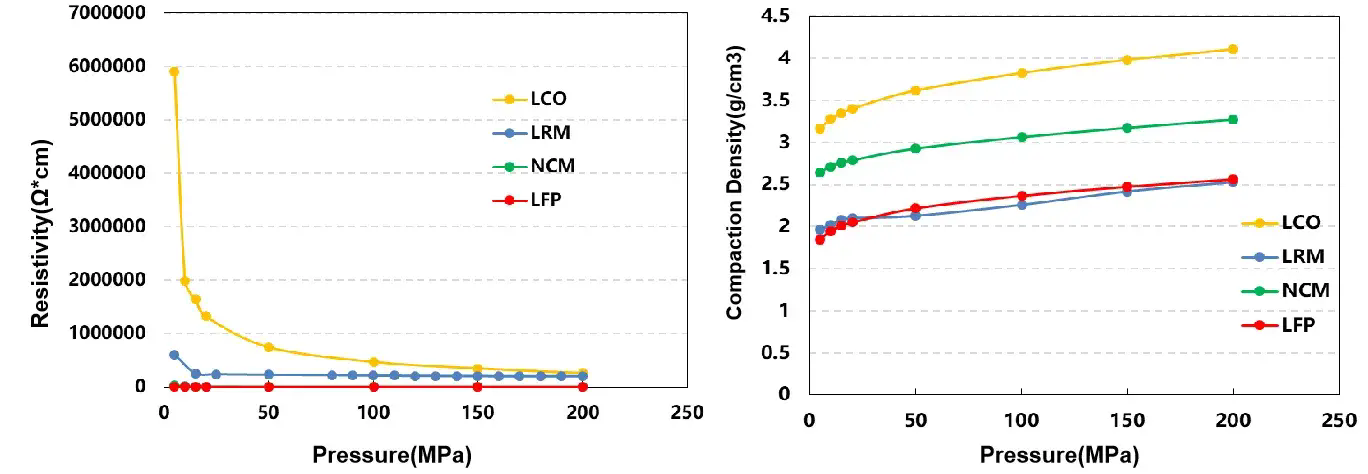

8.1 Cathode Materials under Variable Pressure Mode

1) Parameter: Under 80MPa pressure

2) Resistivity: LCO>LRM>LFP≈LRM;

3) Compaction Density: LCO>NCM>LFP>LRM

4) Conclusion: The compaction density shows minimal diference under high-pressure conditions but varies unde(ow-pressure conditions. This is mainly because samples with a wide particle size distribution have poor flow anc*earrangement characteristics, leading to higher porosity and lower compaction density under low pressure.

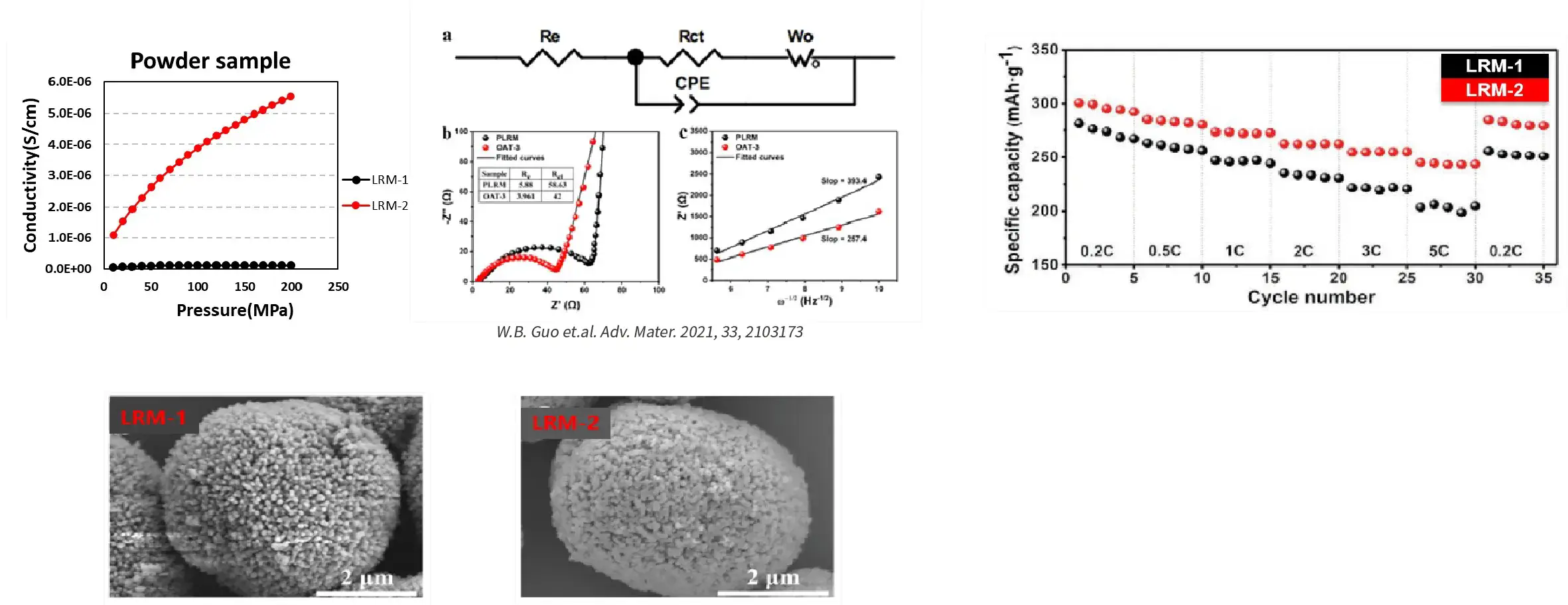

8.2 Lithium-rich Materials Under Variable Pressure Mode

1) Analysis of the lithium-rich material with different modification methods.

2) The resistivity of lithium-rich materials can be reduced by regulating the surface structure!

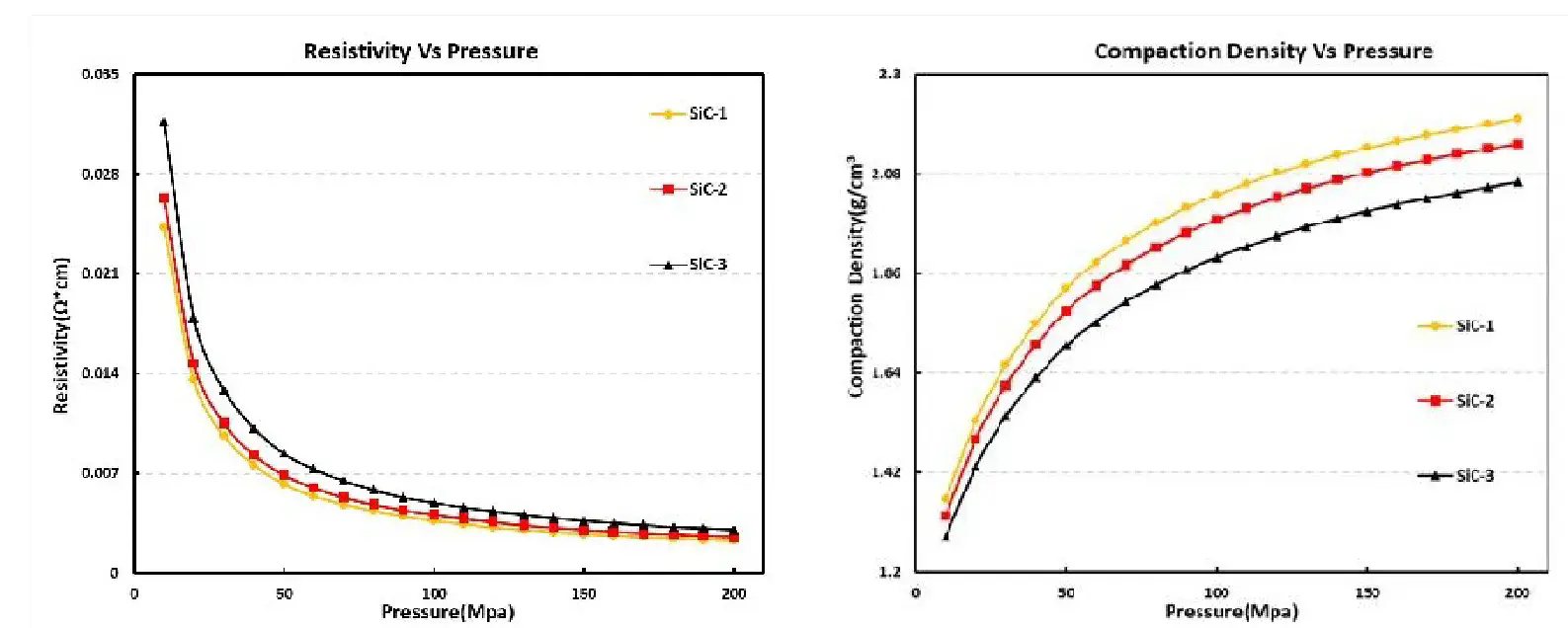

8.3 Silicon-based materials

Test Condition: Si content: 3%, 6% and 10%(SiC-1/Sic-2/sic-3)

Conclusion:

1) Resistivity: Sic-1< Sic-2< SiC-3

2) Compaction density: Sic-1>SiC-2> Sic-3

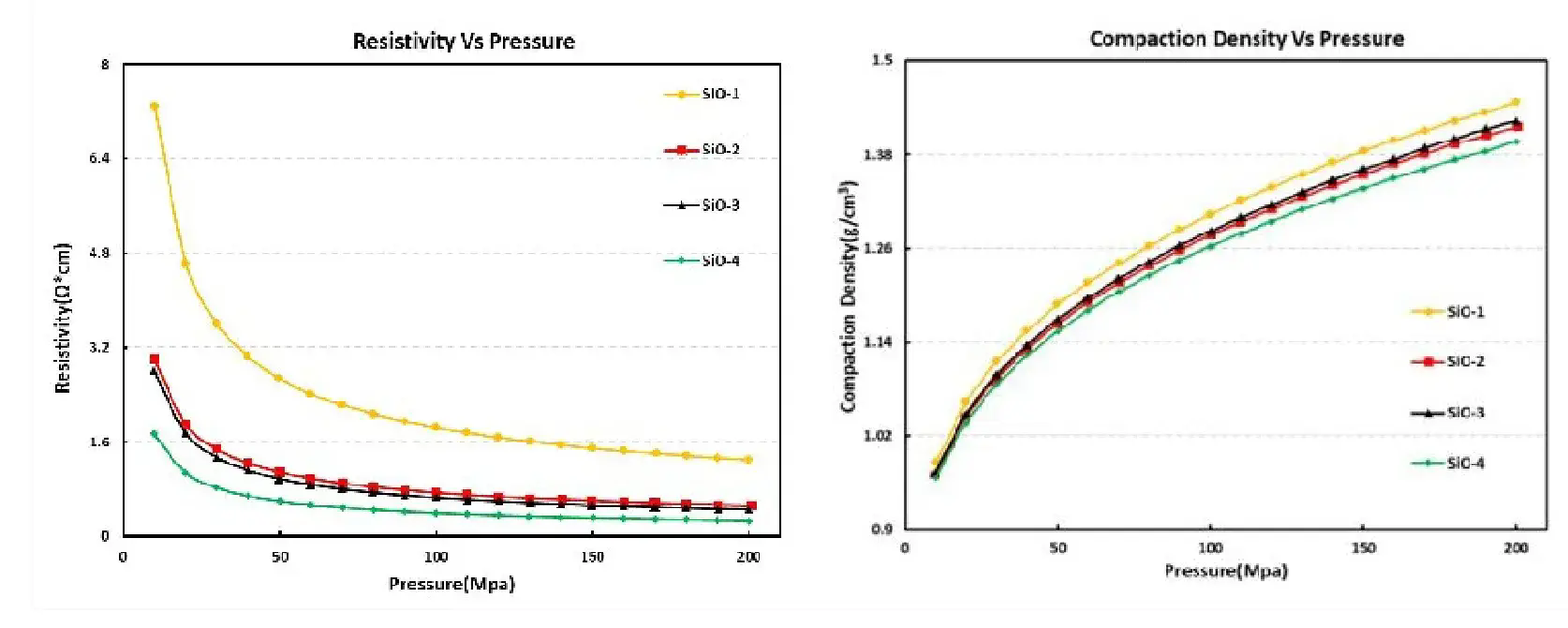

Test condition: Sintering temperature of SiO

Materials: Si0-1< Si0-2<Si0-3<Si0-4

Conclusion:

Resistivity: Sic-1>Si0-2>Si0-3> Si0-4

Compaction density:Sic-l>Si0-2>Si0-3>Si0-4

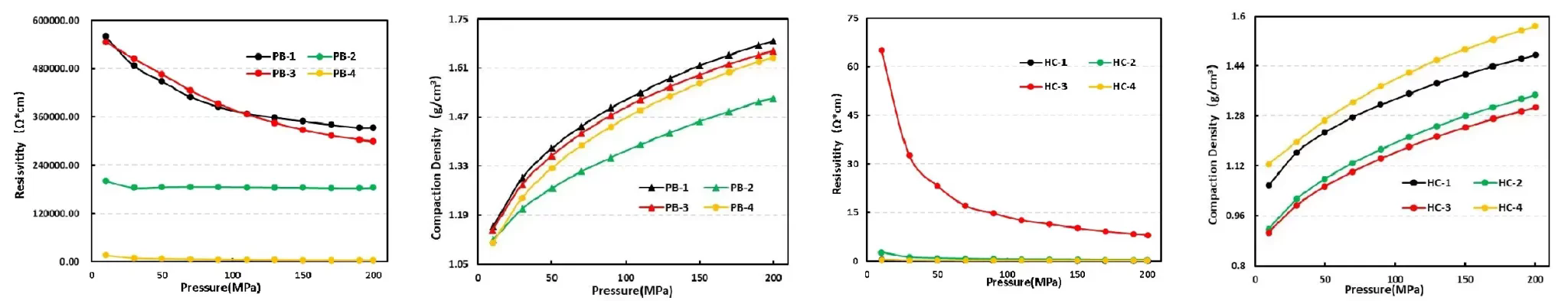

8.4 Anode & Cathode Materials for Sodium ion Battery

Conductivity evaluation of anode & cathode powders for sodium ion batteries : Effectively evaluate the conductivity ane compaction properties of Prussian blue and hard carbon under diferent modification conditions

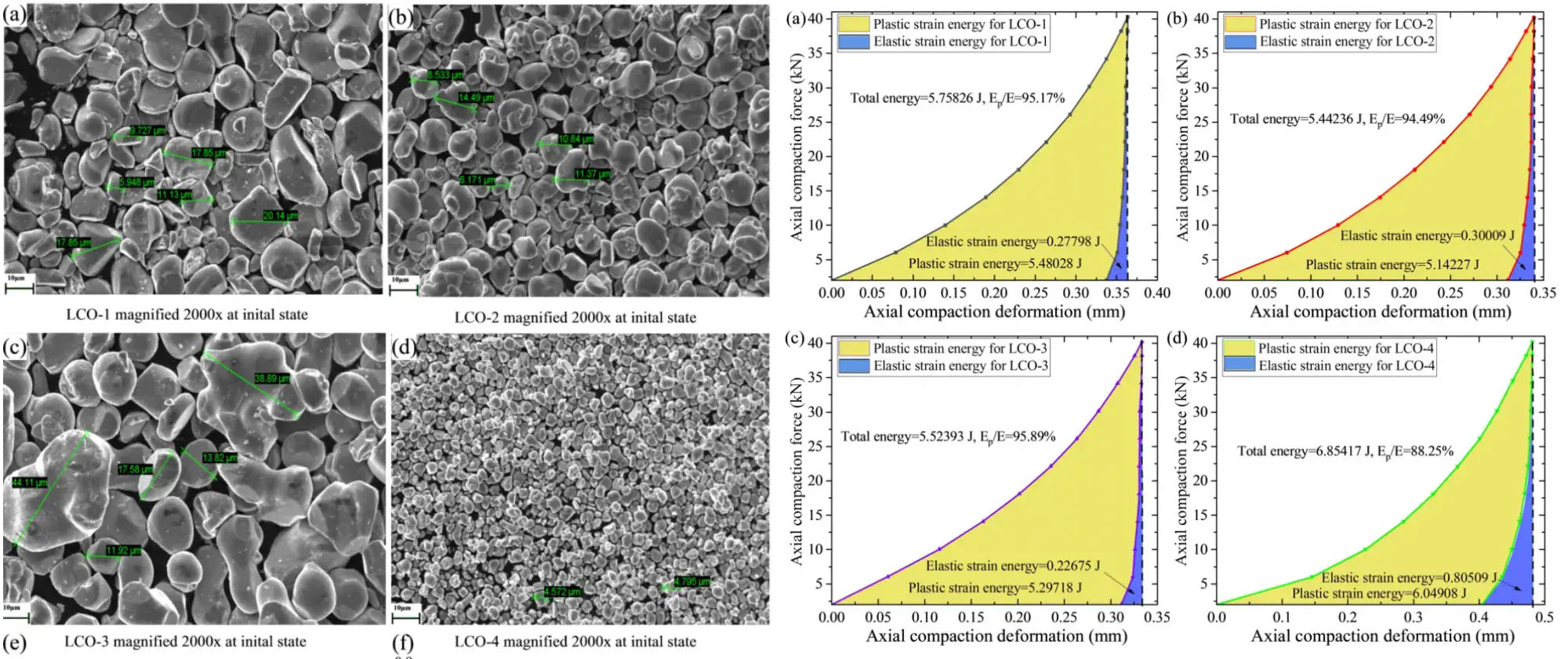

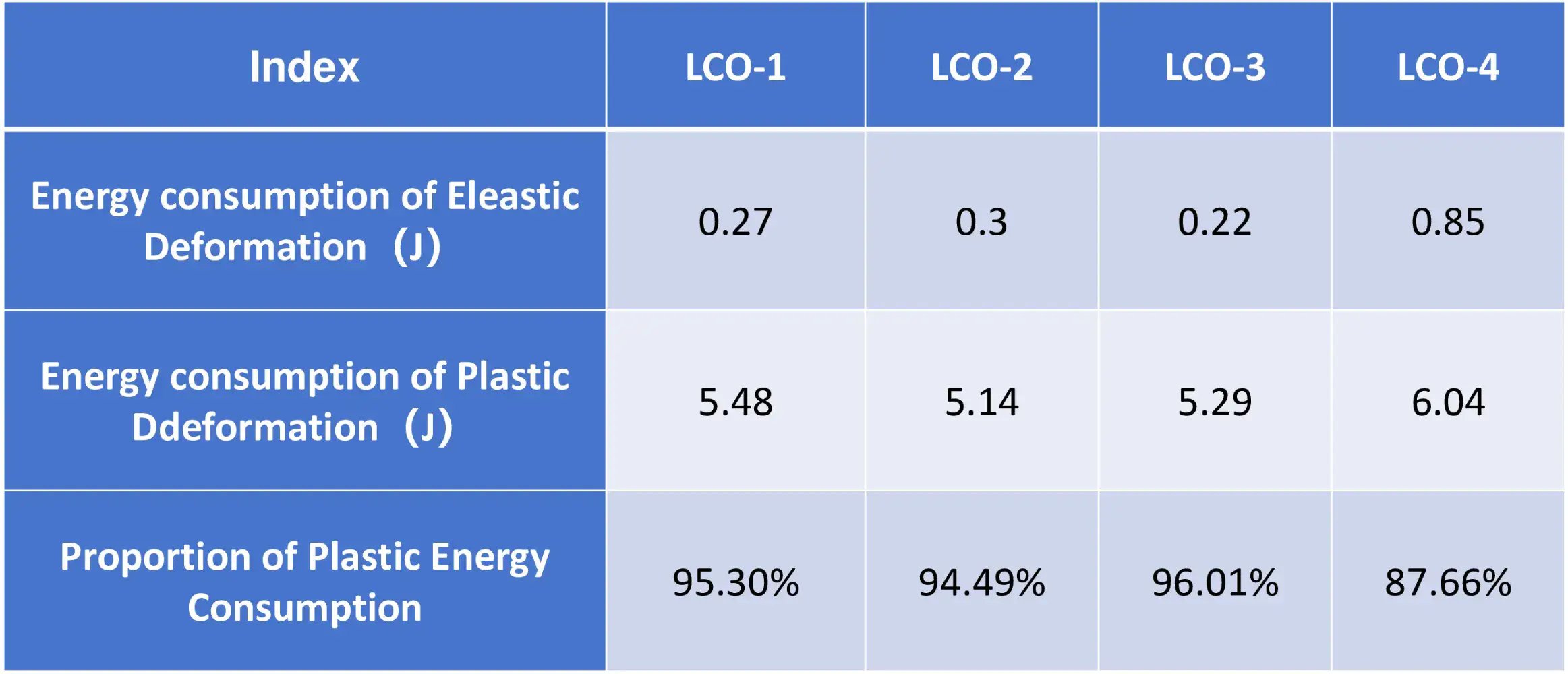

8.5 Elastic Modulus

1) LCO under Steady-state Mode

LCO Particle Size:

LCO-1: 5μm-30μm

LCO-2: 5μm-15μm

LCO-3: 10μm-45μm

LCO-4: 5μm

Conclusion:

During the compaction, plastic deformation typically accounts for approximately 90% of the total deformation.

Powders of smaller particle size(LCO-4) exhibit a more noticeable reboundness, and its proportion of Plastic energy consumption is relatively lower as well.

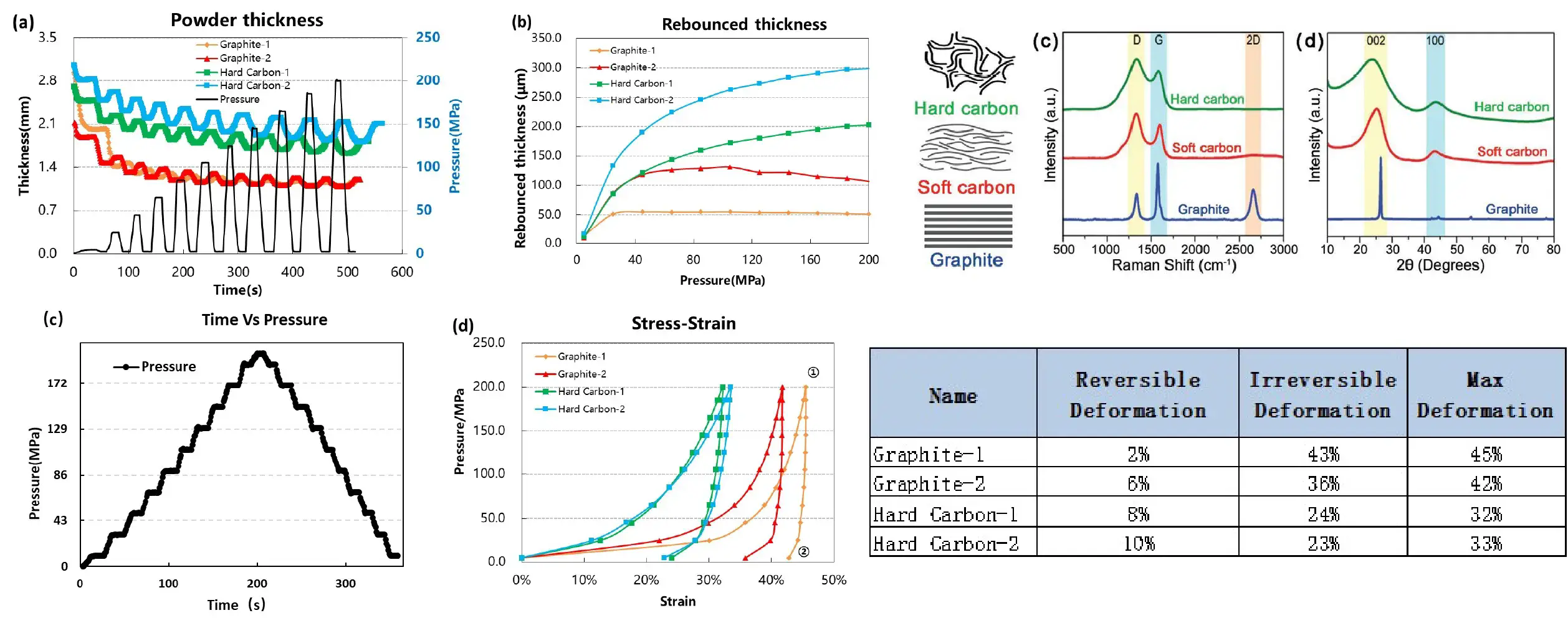

2) Carbon Materials under Pressure Relief & Steady-state Mode

Specifications

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com