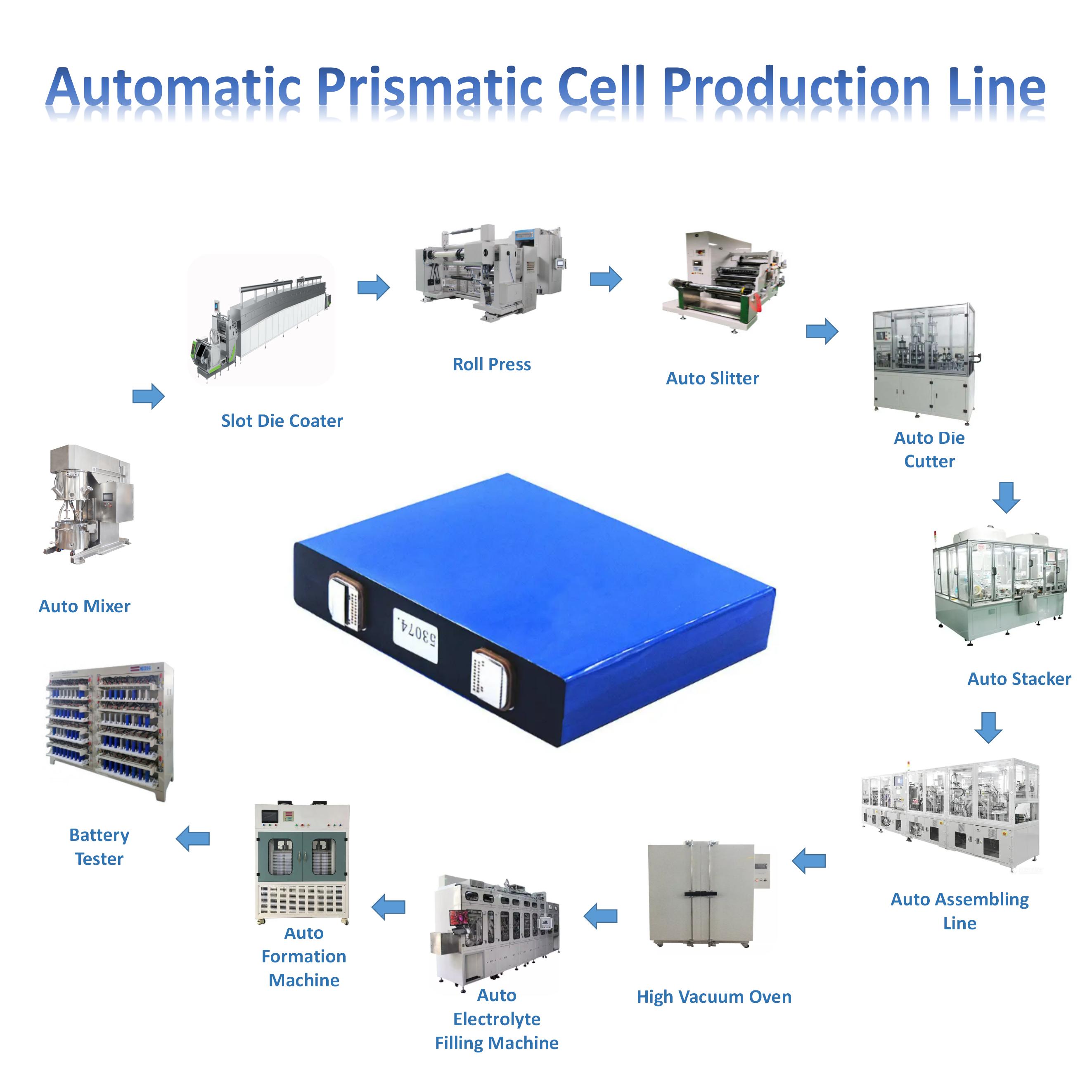

- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

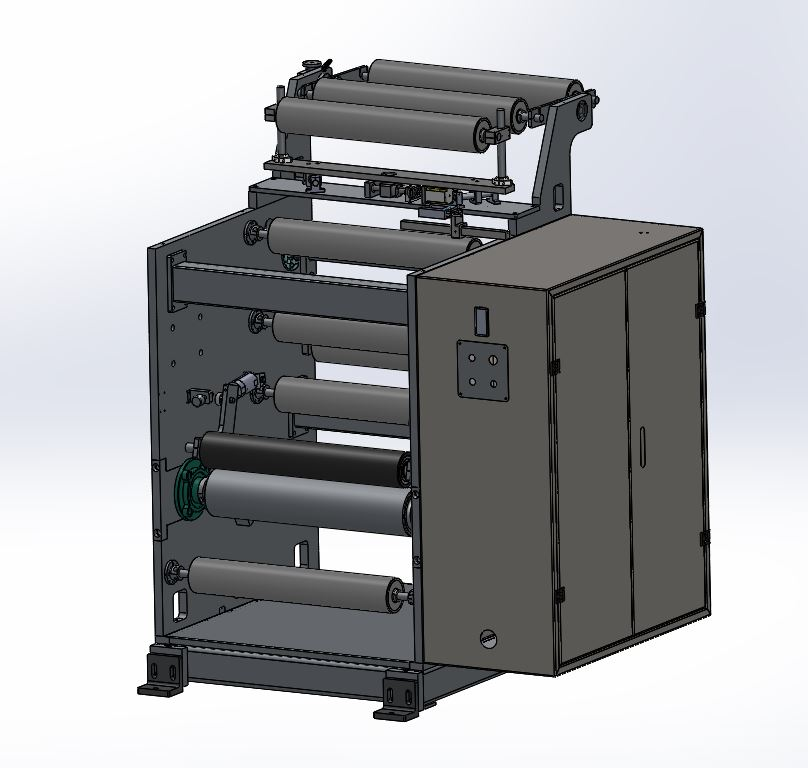

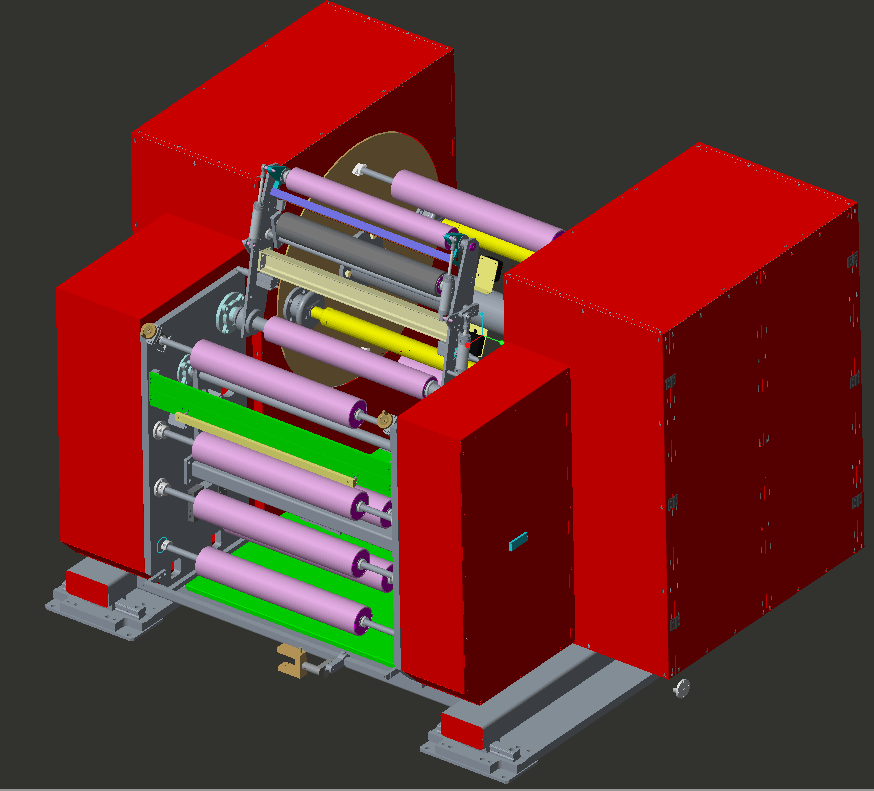

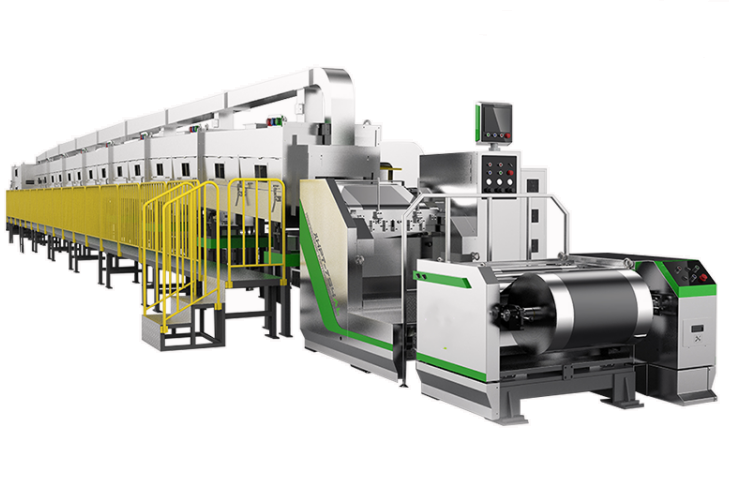

Prismatic Battery Double Sides Slot Die Coater Machine With Winding & Unwinding System

Model Number:

TMAX-ZL-J750-40Compliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Prismatic Battery Double Sides Slot Die Coater Machine With Winding & Unwinding System

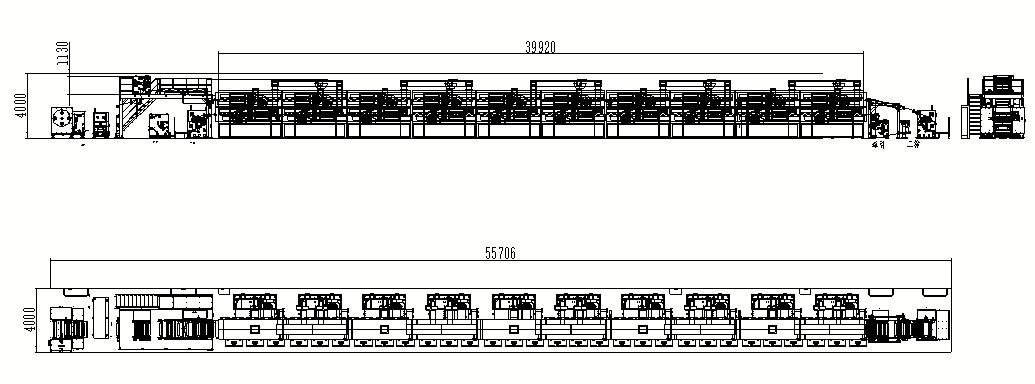

I. Brief introduction of coater structure

1. Unwinding mechanism

2. Coating mechanism (2 sets)

3. Oven mechanism (double-layer 40m)

4. Traction mechanism (2 sets)

5. Winding mechanism

6. Control system

Overall size and weight of coating equipment:

size: length 55000mm * width 4000mm (excluding maintenance space) * height 4000mm

Weight: About 40T

Function overview:

ZL-J series coating machine is a professional lithium battery electrode coating equipment.

▲ it is applicable to the coating process of oily or aqueous lithium iron phosphate, oily lithium cobalt oxide, ternary, lithium manganate, nickel cobalt lithium manganate, oily or aqueous negative carbon graphite, lithium titanate and other slurry systems;

▲ using the full-automatic PID closed-loop tension control system, the tension control accuracy can reach the level of ± 1n;

▲ imported standard parts such as Siemens PLC control system and high-precision servo motor are used to ensure the ultra-high consistency and stability of coating products in terms of surface density and size. The proportion of imported standard parts in the standard parts of the whole machine is as high as 85%.

▲ with the characteristics of high-speed coating, high precision and high consistency, it is the preferred coating equipment for power batteries.

II. Technical parameters and main configuration of equipment

(A)Main configuration of equipment:

|

No. |

Name |

Place of Origin |

|

1 |

Air switch |

Schneider (France) |

|

2 |

PLC |

Siemens (Germany) |

|

3 |

Touch screen |

Siemens (Germany) |

|

4 |

Modular |

Siemens (Germany) |

|

5 |

Intermediate relay |

Schneider (France) |

|

6 |

servo motor |

Siemens (Germany) |

|

7 |

Direct drive servo motor (DDR) |

Rexroth (Germany) |

|

8 |

Feeding pressure detection |

Bd.sensors/valcom (Germany / Japan) |

|

9 |

Precision metering pump |

Heishin (Japan) |

|

10 |

Low friction cylinder |

Tengcang (Japan) |

|

11 |

Planetary reducer |

Newcastle (Germany) |

|

12 |

Circuit breaker |

Schneider (France) |

|

13 |

AC contactor |

Schneider (France) |

|

14 |

Solid state relay |

Xinda (Taiwan) |

|

15 |

Thermal protection |

Schneider (France) |

|

16 |

Thermostat |

Omron (Japan) |

|

17 |

Automatic deviation correction |

Aibo (domestic) |

|

18 |

Full automatic tension |

PID closed loop control (self-made) |

|

19 |

Main discharging (receiving) motor |

Siemens (Germany) |

|

20 |

Optical fiber electric eye |

KEYENCE (Japan) |

|

21 |

Deep groove ball bearing (machine head) |

NSK (Japan) |

|

22 |

Coating roller |

Hard chromium plating (self-made) |

|

23 |

Guide roller |

Φ 118 aluminum alloy surface anodized, finish rc0.4 (domestic) |

|

24 |

Frequency converter |

Rexroth (Germany) |

|

25 |

Knife adjusting grating ruler |

Keens (Japan) |

|

26 |

Fan (stainless steel) |

Hongjian (domestic) |

|

27 |

Extrusion head |

Mitsubishi |

|

28 |

Digital pressure gauge |

Bode (Sweden) |

|

29 |

Pneumatic components |

SMC (Japan) |

|

(B)Vulnerable parts: |

|||||

|

No. |

Name |

Brand |

Quantity |

Stock time |

Remarks |

|

1 |

Steel roller |

self-control |

1 piece /2 sets |

30 days |

Imported chrome plating materials |

|

2 |

Steel roller bearing |

NSK/NTN |

2 /1 set |

15 days |

According to the procurement cycle |

|

3 |

Heating tube |

domestic |

3 pieces / set |

1 day |

|

|

4 |

Thermocouple |

domestic |

1 piece / set |

1 day |

Adapt to the longest drying path |

|

5 |

inner hexagon spanner |

domestic |

1 set / set |

1 day |

|

|

6 |

Adjustable wrench |

domestic |

1 piece / set |

1 day |

|

|

7 |

Valve body sealing ring |

domestic |

1 set / unit |

1 day |

|

|

8 |

Torque wrench |

Japan |

1 set / unit |

15 days |

|

|

9 |

Die head lifting truck |

domestic |

1 set / unit |

15 days |

|

|

10 |

Marble platform |

domestic |

1 set / unit |

10 days |

|

|

11 |

Feeding pipe |

domestic |

12m / set |

1 day |

|

|

12 |

Pole sampler |

domestic |

1 / set |

2 days |

|

|

13 |

Shim |

TMAX |

3 sets / unit |

15 days |

|

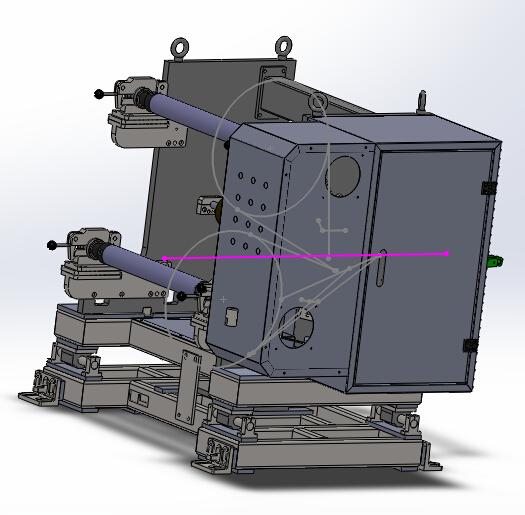

(C)Automatic feeding system:A set of automatic feeding system (60L) is standard.

(D)Appearance color: Except for the stainless steel part, the color of the box conforms to the standard color card provided by the demander.

(E)Device functions:

|

No. |

Project |

Technical parameter |

Notes |

|

1 |

Suitable system |

Oily or aqueous lithium iron phosphate, lithium cobalt oxide, lithium manganate, ternary, nickel cobalt lithium manganate, lithium titanate, carbon graphite, etc |

|

|

2 |

Operating substrate parameters |

Aluminum foil (Cu): thickness 9 ~ 25um; Width 300 ~ 720mm; Roll diameter max.500mm; Weight max.500kg; |

|

|

Copper foil (Cu): thickness 4.5 ~ 30um; Width 300 ~ 720mm; Roll diameter max.500mm; Weight max.500kg; |

Either single side light or double side light |

||

|

3 |

Design width of roll surface |

750 mm |

|

|

4 |

Guaranteed coating width |

200~680mm |

|

|

5 |

Equipment mechanical running speed |

40m/min |

|

|

6 |

Equipment coating speed |

1-32/min; |

It depends on the drying condition |

|

7 |

Suitable for slurry viscosity |

2000~16000 Cps(Positive pole) 1000~16000 Cps(Negative pole) |

|

|

8 |

Single side coating dry thickness range |

40~200g/m2 |

|

|

9 |

Minimum intermittent length |

Coating speed < 5mm within 15m/min; Coating speed above 25m/min < 8mm; |

|

|

10 |

Minimum coating length of multiple sections |

50mm |

Coating speed≤12m/min |

|

11 |

Solvent properties |

Oily solvent NMP(s.g=1.033,b.p=204℃) |

|

|

Aqueous solvent H2O/NMP(s.g=1.000,b.p=100℃) |

|

||

|

12 |

Suitable solid content |

Positive electrode S.C. 60%±20% |

|

|

Negative pole S.C. 50%±15%(PVDF system) S.C. 50%±10%(SBR system) |

|

||

|

13 |

Proportion |

Positive electrode 1.5—2.59/cm2 Negative pole 1~1.89/cm2 |

|

|

14 |

Coating method |

Double layer front and back 3-stage unequal interval coating / second side automatic tracking / continuous coating / field lattice coating |

|

|

15 |

Roll change mode |

Manual |

|

|

16 |

Substrate running direction |

Forward coating, substrate forward and reverse empty foil operation |

|

(F)Structure introduction of each part:

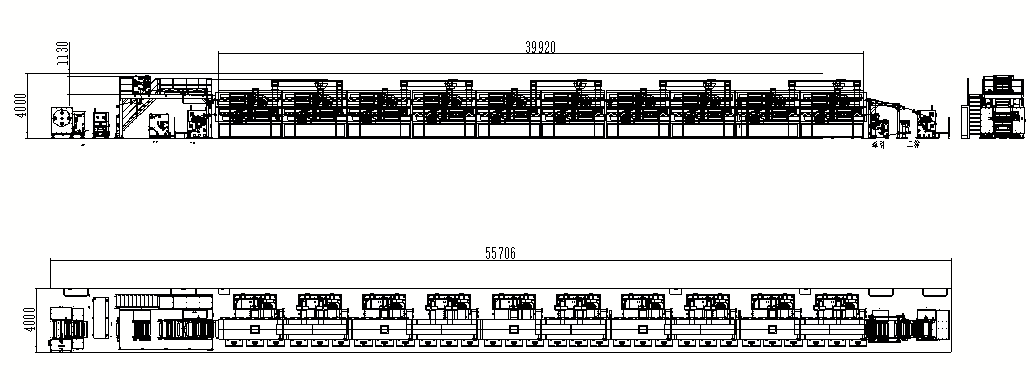

1、 Unwinding mechanism (double arm double support manual rewinding):

|

No. |

Project |

Technical parameter |

Notes |

|

1 |

Installation structure mode |

CNC processing thickness of 70 mm integral vertical plate structure, the overall weight of 2.6 tons, increase the ground bearing iron plate, reduce the ground bearing area. |

|

|

2 |

Main drive motor |

Servo motor |

|

|

3 |

Rubber roller structure |

To prevent the tension instability caused by the non separation of tension and ensure the stability of the coating surface density. |

|

|

4 |

Distance adjustment between die head and coating roller |

The servo motor cooperates with the high-precision absolute displacement sensor for closed-loop tracking control. The distance is set through the screen, 1~5000um, the adjustment resolution is 0.1um, and the repeated positioning accuracy is ≤± 0.3um. |

|

|

5 |

Die head selection |

The die lip of Mitsubishi special extrusion head is made of high wear-resistant and corrosion-resistant cemented carbide steel, and the surface is treated with tungsten carbide or chromium nitride. The straightness and flatness are ≤ 1.5 µ M |

|

|

6 |

Die cavity structure |

The multi pressure cavity slit (spray) coating head is adopted, which has strong process adaptability and helps to balance the transverse pressure, so as to make the transverse coating thickness consistent; The upper die of the coating head is designed with a deflection adjusting mechanism, which can adjust the parallelism of the upper and lower die lips |

|

|

7 |

Pressure monitoring system |

Feed pressure monitoring, reflux pressure monitoring, die cavity pressure monitoring; It can monitor the feeding process in real time, and give an alarm when there is blockage, with an accuracy of ≤ 0.001mpa |

|

|

8 |

Feeding system |

Japanese bingshen precision screw pump (2nbl15f (sus+epdm) pump) + precision servo motor, an effective 60L turnover bucket (material container), and has the functions of liquid level detection and liquid level mixing to prevent the sedimentation and overflow of slurry. |

|

|

9 |

Coating intermittent function |

Servo intermittent control valve system is adopted to ensure the stability of coating size. |

|

|

10 |

Head and tail thinning function |

The servo intermittent control valve system can adjust the head and tail thinning time and the stroke of the intermittent valve switch to adjust the head and tail thickness in real time. |

|

|

11 |

Die head horizontal adjustment function |

Adopt precise linear guide rail guidance and manual horizontal adjustment mode, so that the die head can be slightly adjusted ± 10mm in the horizontal position; Ensure the vertical alignment accuracy of the front and back sides |

|

|

12 |

Matching and assembly of the upper part of the die head and the lower part of the die head |

The digital torque wrench is used to ensure the assembly consistency and accuracy of the die head. |

|

|

13 |

Roller surface treatment |

Surface oxidation treatment of metal aluminum roller, surface hardness HRC65; Over roll circular runout ≤ 20 μ m; Surface roughness Ra0.2; Parallelism ≤ 0.1mm; |

|

|

14 |

Coating roll (steel roll) |

The surface is plated with imported hard chromium, with a diameter of Φ 295mm; |

|

|

15 |

Tension |

Full automatic PID closed-loop control constant tension, tension range 1 range 0~50n, tension control accuracy ± 1n |

|

|

16 |

Stand alone head position |

Installation and operation before drying |

|

|

17 |

Laser alignment function |

The laser alignment function is used to manually judge the alignment degree. |

|

2、 Head structure (one coat, two coats):

|

No. |

Project |

Technical parameter |

Notes |

|

1 |

Installation structure mode |

CNC processing thickness of 70 mm integral vertical plate structure, the overall weight of 2.6 tons, increase the ground bearing iron plate, reduce the ground bearing area. |

|

|

2 |

Main drive motor |

Servo motor |

|

|

3 |

Rubber roller structure |

To prevent the tension instability caused by the non separation of tension and ensure the stability of the coating surface density. |

|

|

4 |

Distance adjustment between die head and coating roller |

The servo motor cooperates with the high-precision absolute displacement sensor for closed-loop tracking control. The distance is set through the screen, 1~5000um, the adjustment resolution is 0.1um, and the repeated positioning accuracy is ≤± 0.3um. |

|

|

5 |

Die head selection |

The die lip of Mitsubishi special extrusion head is made of high wear-resistant and corrosion-resistant cemented carbide steel, and the surface is treated with tungsten carbide or chromium nitride. The straightness and flatness are ≤ 1.5 µ M |

|

|

6 |

Die cavity structure |

The multi pressure cavity slit (spray) coating head is adopted, which has strong process adaptability and helps to balance the transverse pressure, so as to make the transverse coating thickness consistent; The upper die of the coating head is designed with a deflection adjusting mechanism, which can adjust the parallelism of the upper and lower die lips |

|

|

7 |

Pressure monitoring system |

Feed pressure monitoring, reflux pressure monitoring, die cavity pressure monitoring; It can monitor the feeding process in real time, and give an alarm when there is blockage, with an accuracy of ≤ 0.001mpa |

|

|

8 |

Feeding system |

Japanese bingshen precision screw pump (2nbl15f (sus+epdm) pump) + precision servo motor, an effective 60L turnover bucket (material container), and has the functions of liquid level detection and liquid level mixing to prevent the sedimentation and overflow of slurry. |

|

|

9 |

Coating intermittent function |

Servo intermittent control valve system is adopted to ensure the stability of coating size. |

|

|

10 |

Head and tail thinning function |

The servo intermittent control valve system can adjust the head and tail thinning time and the stroke of the intermittent valve switch to adjust the head and tail thickness in real time. |

|

|

11 |

Die head horizontal adjustment function |

Adopt precise linear guide rail guidance and manual horizontal adjustment mode, so that the die head can be slightly adjusted ± 10mm in the horizontal position; Ensure the vertical alignment accuracy of the front and back sides |

|

|

12 |

Matching and assembly of the upper part of the die head and the lower part of the die head |

The digital torque wrench is used to ensure the assembly consistency and accuracy of the die head. |

|

|

13 |

Roller surface treatment |

Surface oxidation treatment of metal aluminum roller, surface hardness HRC65; Over roll circular runout ≤ 20 μ m; Surface roughness Ra0.2; Parallelism ≤ 0.1mm; |

|

|

14 |

Coating roll (steel roll) |

The surface is plated with imported hard chromium, with a diameter of Φ 295mm; |

|

|

15 |

Tension |

Full automatic PID closed-loop control constant tension, tension range 1 range 0~50n, tension control accuracy ± 1n |

|

|

16 |

Stand alone head position |

Installation and operation before drying |

|

|

17 |

Laser alignment function |

The laser alignment function is used to manually judge the alignment degree. |

|

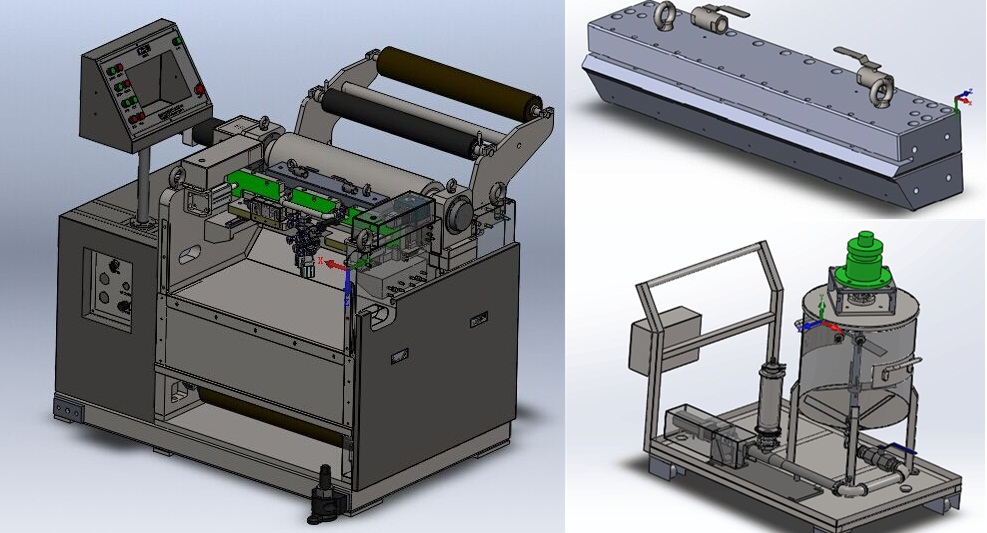

3、 Drying channel (suspension oven)

|

No. |

Project |

technical parameter |

Remark |

|

1 |

Oven structure |

The first four sections are the main transmission ship structure, and the last six sections are the suspension oven structure. |

|

|

2 |

Oven length |

40 meters (4 meters / section, 10 sections in total) |

|

|

3 |

Texture of material |

Stainless steel, inner tank national standard SUS304, outer tank national standard SUS201 |

|

|

4 |

Driving mode of oven guide roller |

The first four sections are the main transmission structure, and the last six sections are the suspension oven |

|

|

5 |

temperature control |

It is divided into the protection control of normal working temperature control and overtemperature monitoring alarm. In case of overtemperature, an audible and visual alarm will appear, and the main heating power supply will be cut off; Each section is completely controlled independently |

|

|

6 |

Heating way |

Electric heating, hot air circulation structure |

|

|

7 |

Heating power of single section oven |

Single section 24kw/4m (maximum starting power) |

|

|

8 |

Temperature in drying channel |

Design Max150 ℃, temperature difference in the area of single section oven ≤ 5 ℃ |

|

|

9 |

Box surface temperature during operation |

≤45℃; The cotton filling thickness is 100mm; |

|

|

10 |

Blowing mode |

Upper and lower air blowing, upper and lower air volume can be controlled respectively through valves, which can be fine tuned; The upper and lower air chambers share the heating body |

|

|

11 |

Exhaust volume control of each section |

Independent control and fine adjustment through mechanical valve |

|

|

12 |

Air nozzle structure |

The blowing direction of the first four sections is 30 degrees from the horizontal, and the air nozzle groove is slotted with a special mold. The last five sections are adjustable air nozzle hooks. |

|

|

13 |

Fan control |

AC contactor control |

|

|

14 |

Heating control |

Solid state relay |

|

|

15 |

Fan material |

National standard SUS304 stainless steel |

|

|

16 |

Solvent recovery system |

No, only assist in the installation of interfaces |

|

|

17 |

NMP solvent concentration alarm |

Provide installation interface. (to be quoted separately) |

|

|

18 |

Air chamber pressure monitoring |

None (this function needs to be quoted separately) |

|

|

19 |

Exhaust air volume |

35000 m3 / h max |

|

4、 Traction mechanism: (2 sets)

|

No. |

Project |

technical parameter |

Notes |

|

1 |

Marching correction |

Installed at the outlet of drying channel, automatic EPC control, swing ± 15 degrees, photoelectric sensor |

|

|

2 |

Tension |

Double closed loop speed control mode: 1. Swing roll PID synchronous control 2. Servo motor adjusts tension in closed loop. Tension display table shows tension value 3. The adjustable tension range is 0--300n, and tension fluctuation ≤± 1.5% |

|

|

Tension partition is realized by pinch roll and traction roll |

|

||

|

3 |

Installation structure mode |

Installation of integral vertical plate of CNC machining center (thickness 30mm) |

|

|

4 |

Traction roller |

160mm steel roller |

|

|

5 |

Pinch roll |

Ø 120mm rubber roller, surface bread EPDM |

|

|

6 |

Drive motor |

The traction roller is driven by Siemens Servo motor + precision reducer |

|

5、 Rewinding mechanism (disc type double shaft automatic rewinding):

|

No. |

Project |

technical parameter |

Notes |

|

1. |

Installation structure mode |

Installation of integral vertical plate of CNC machining center (thickness 30mm) |

|

|

2. |

tension |

Double closed loop speed control mode: 1. Swing roll PID synchronous control 2. Servo motor adjusts tension in closed loop. Tension display table shows tension value 3. The adjustable tension range is 0--300n, and tension fluctuation ≤± 1.5% |

|

|

3. |

Rectify deviation |

Automatic EPC control, stroke 120mm |

|

|

4. |

Maximum winding diameter |

Ø800 |

|

|

5. |

Winder inflatable shaft |

Article 2 (national standard) |

|

|

6. |

Winding motor |

The winding power is driven by Siemens Servo motor + precision reducer |

|

|

7. |

Max capacity |

600Kg |

|

|

8. |

Roll change mode |

Automatic winding and changing function without shutdown |

|

6、 Control system:

|

No. |

Project |

technical parameter |

Notes |

|

1 |

Master control system |

Touch screen, PLC, module, servo system |

|

|

2 |

Operation mode |

Manual, automatic and emergency stop; The whole machine can be operated before and after |

|

|

The coating line speed, coating setting, head and tail thinning setting, fan frequency and temperature setting can be set, displayed and recorded through the touch screen |

|

||

|

3 |

Setting range of coating and intermittent length |

Coating length 20.0 ~ 3200.0mm |

|

|

4 |

Alarm condition |

Intermittent length: 5.0 ~ 3200.0mm |

|

|

5 |

Counting function |

When the equipment fails, the touch screen will display the corresponding correction screen |

|

|

6 |

Head and tail thickness adjustment method |

Production quantity / length |

|

III、 Equipment accuracy

1、Hardware accuracy

|

No. |

Project |

technical parameter |

Notes |

|

1 |

Coating roll (steel roll) |

Circular runout ≤ 1.0 um, Ra0.4 straightness ≤ 1.5um |

|

|

2 |

Deviation correction |

±1mm |

|

|

3 |

Aluminum roller |

Circular runout ≤ 20um, straightness ≤ 20um |

|

|

4 |

Tool adjustment control repetition accuracy |

±0.1um |

|

|

5 |

Temperature control accuracy |

±0.5℃ |

|

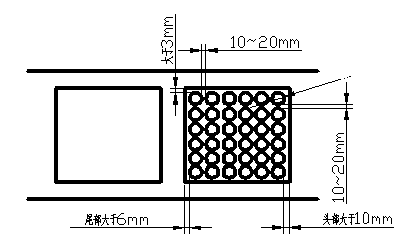

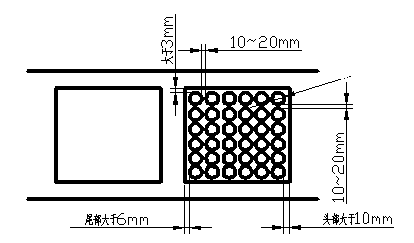

2、Coating accuracy

|

Item |

Sign |

Parameters (30m/min) |

|

|

A (trailing) |

≤ 1mm (related to slurry viscosity and binder characteristics) |

|

B (abnormal head area) |

5mm |

|

|

C (tail abnormal area) |

6mm |

|

|

D (edge effect area) |

≤3mm; Thickness -10 um |

|

|

E (length error) |

±0.5mm |

|

|

F (width error) |

±0.5mm |

|

|

M (width error) |

±0.5mm |

|

|

G1 (head thickness) |

-5~+5um |

|

|

G2 (tail thickness) |

-5~+5um |

|

|

H (blank error) |

±0.5mm |

|

|

I (positive and negative alignment error) |

±0.5mm |

|

|

J single surface density (remove areas B, C and D) |

Within 1.2% |

|

|

Length range |

L1 (film length) |

20.0~3200.0mm |

|

L2 (intermittent length) |

5.0~3200.0mm |

|

|

L1 /l2 (coating + intermittent length) |

L1 +L2 ≥120mm |

3、Measuring method

A. Measuring area: 3mm at the edge, 5mm at the end and 5mm at the beginning.

B. Measure dimensions Φ 40mm or according to the process requirements of the demander

IV、 Installation and use environment

1) The ambient temperature of the machine head is 20~30 ℃, and the rest is 10~40 ℃;

2) Relative humidity of the machine head: positive RH ≤ 35%, negative RH ≤ 98%, and the rest ≤ 98%;

V、 Supporting facilities

1) Power supply: 3Ph 380V, 50Hz, voltage fluctuation range: +8% - 8%; The total starting power of the power supply is 280KW;

2) Compressed air: after drying, filtering and stabilizing, the outlet pressure is greater than 5.0kg/cm2;

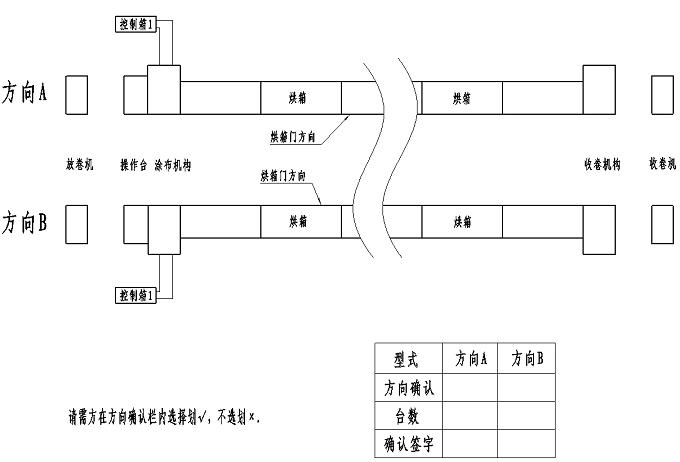

VI 、 Device orientation (optional)

Attached table: detailed list of equipment pre acceptance and formal acceptance inspection items (inspection results are attached with acceptance report)

|

No. |

Inspection items |

Inspection standard |

Inspection method |

|

1. |

Device configuration parameters |

Overall dimension of equipment: L (56000mm) *W(4000mm) *H (4000mm) |

Tape measure |

|

Oven length: (4m/ section) × 4) + (4m/ section × 6 sections) =40m |

ruler |

||

|

Maximum winding diameter of winding and unwinding: φ 600mm |

ruler |

||

|

Roll width: 750mm |

|

||

|

2. |

Integrity of equipment function composition |

Unwinding part (manual roll change function, tension, deviation correction, inflatable shaft) |

Visually check the technical agreement and equipment configuration table |

|

Coating part (base, coating roller, feeding system, domestic manest die) |

|||

|

Oven (circulator, heating system, external auxiliary air duct) |

|||

|

Traction part (travel deviation correction, traction tension, traction roller assembly) |

|||

|

Winding part (manual roll change function, tension, deviation correction, inflatable shaft) |

|||

|

Control system (electrical cabinet, internal wiring, external trunking wiring) |

|||

|

Delivery parts (according to the content of the technical agreement) |

|||

|

3. |

Brand confirmation of standard parts |

100% according to the brand of purchased parts specified in the technical agreement |

|

|

4. |

Safety standards |

Mechanical and electrical interlocking, self-locking function, induction protection function; |

Visual inspection and operation |

|

Alarm bell prompt in each area before equipment startup; |

Operation |

||

|

Safety warning signs shall be set at dangerous parts such as movement, compression, cut-off and heat source; |

visual |

||

|

Emergency stop switch button, safety rope in internal maintenance area (at least 3 places); |

visual |

||

|

Protective covers for transmission and moving parts; |

visual |

||

|

Oven overtemperature alarm and power-off protection function |

operation |

||

|

5. |

Mechanical accuracy test |

Coating roll circular runout ≤ 1.0 μ m; Straightness ≤ 1.5 μ m; Surface roughness Ra0.4, |

Dial indicator, special inspection tool |

|

Over roll circular runout ≤ 20 μ m; Surface roughness Ra0.2 |

Dial indicator |

||

|

Parallelism of roller passing ≤ 0.1mm (except for roller passing of oven) |

Dial indicator, special inspection tool |

||

|

6. |

Empty belt operation (operate the base material continuously at a speed of 40m/min for about 500m) |

1m/min→10m/min→30m/min Sectional sampling |

Tachometer |

|

No wrinkling in the whole area and no scratch on the surface of the substrate |

visual |

||

|

All moving parts operate smoothly without abnormal noise; The transmission belt is free of deviation and wear; |

visual |

||

|

Temperature setting of each section of the oven: normal temperature ~ 150 ℃ |

Operation and visual inspection |

||

|

The winding, unwinding and traction deviation correction run smoothly without continuous shaking |

Operation and visual inspection |

||

|

Except for deviation correction and oven, the deviation of the base material of each roller is ≤± 1mm; Deviation of coating roll substrate ≤ 0.5mm |

calipers |

||

|

Tension setting value 5 ~ 300N |

Operation and visual inspection |

||

|

When starting and stopping, the tension fluctuation is ± 5N; Tension fluctuation ± 1n during normal operation; |

Operation and visual inspection |

||

|

7. |

Coating inspection 30m/min coating operation 1200m) |

The coating speed is 30m/min, and the coating method can realize continuous and intermittent coating |

Parameter setting |

|

The feeding system and pipeline are well sealed without material leakage |

visual |

||

|

The appearance of the coated surface is good, without particles, scratches, exposed foil and poor bulge edge |

visual |

||

|

Density accuracy of one side: weight error ≤± 1.2% (excluding the range of 8mm at the edge) |

Micrometer electronic scale |

||

|

Density accuracy of double-sided surface: weight error ≤± 1.5% (excluding the range of 8mm at the edge) |

Micrometer electronic scale |

||

|

Tailing ≤ 1mm (related to slurry viscosity and binder characteristics) |

ruler |

||

|

Head abnormal area ≤ 8mm |

Ruler, micrometer |

||

|

Tail abnormal area ≤ 6mm |

Ruler, micrometer |

||

|

Edge effect area ≤ 3mm, -10 ~ +5um (slurry viscosity change less than ± 300cps) |

Ruler, micrometer |

||

|

Length error /h blank error: ≤± 0.5mm |

ruler |

||

|

Width error: ≤± 0.5mm |

ruler |

||

|

Thickness of head and tail: -5 ~ +5um |

Micrometer |

||

|

Positive and negative horizontal alignment error: ≤± 0.5mm |

Needle, ruler |

||

|

Longitudinal alignment error of front and back sides: ≤± 0.5mm |

Needle, ruler |

||

|

Temperature control accuracy of single section oven: ≤± 1 ℃ |

visual |

||

|

In the horizontal area 10mm above the substrate, the temperature deviation of each point of a single section oven: ≤± 3 ℃ |

thermodetector |

||

|

Dryness test, solvent residue: ≤ 1% (constant temperature and humidity space sampling measurement) |

Micrometer electronic scale |

||

|

Equipment utilization rate: ≥ 97% (formal acceptance project) |

Operation and test |

||

|

Product qualification rate: ≥ 98% (formal acceptance project) |

Operation and test |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com