- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Lab VIM Process Temperature Induction Melting Furnace with 50 Program Temperature Control System

Model Number:

TMAX-MeltingFurnace1Compliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Lab VIM Process Temperature Induction Melting Furnace with 50 Program Temperature Control System

The medium frequency induction heating, vacuum induction melting furnace adopts the 50 program temperature control system, PID control, temperature control, furnace adopts imported polycrystalline alumina fiber materials, has quick elevating temperature rate, the advantages of convenient, concise, universities, research institutes, industrial and mining enterprises do ideal high temperature smelting, foundry products..

Software control system (choose) :

this furnace is equipped with communication interface and software, can be directly through the furnace computer control of each parameter, and can be observed from the computer PV on the stove and SV temperature and the running situation, the actual temperature of the furnace curve drawing computer real time, and can keep the temperature data of each time, can call up at any time.

Sealing system:

the furnace tube and flanges are sealed with silicone o-ring, easy to remove, retractable, good air tightness, and ensure that the pressure gauge of 12 hours is not deflected.

Vacuum system:

the furnace is equipped with a vrd-8 vacuum pump, and a molecular pump can be used if a higher vacuum degree is required, and smoke filters and oil pollution filters can be selected.

Furnace material:

adopt Japan imported furnace material, not drop powder, material heat preservation performance good, reflectance high, temperature field balance, anti - heat gain cold - shrinkage ability.

Leakage protection function:

the furnace is equipped with a leaky air switch to ensure the safety of use when the furnace leaks power.

Gas supply system (optional) : the customer can control the flow rate of the gas through float meter or proton flow meter (please check the selection).

Flange: using double ring sealing technology, the atmosphere of flange is improved effectively, the flange is equipped with various joints, the resistance vacuum gauge, the KF25 corrugated pipe can be made into the hinge type which can be easily removed.

Water cooling system: the reboiler is equipped with a cold water machine, which can provide cooling water for the induction coil effectively. The water cooling system has the function of automatic temperature control and temperature protection.

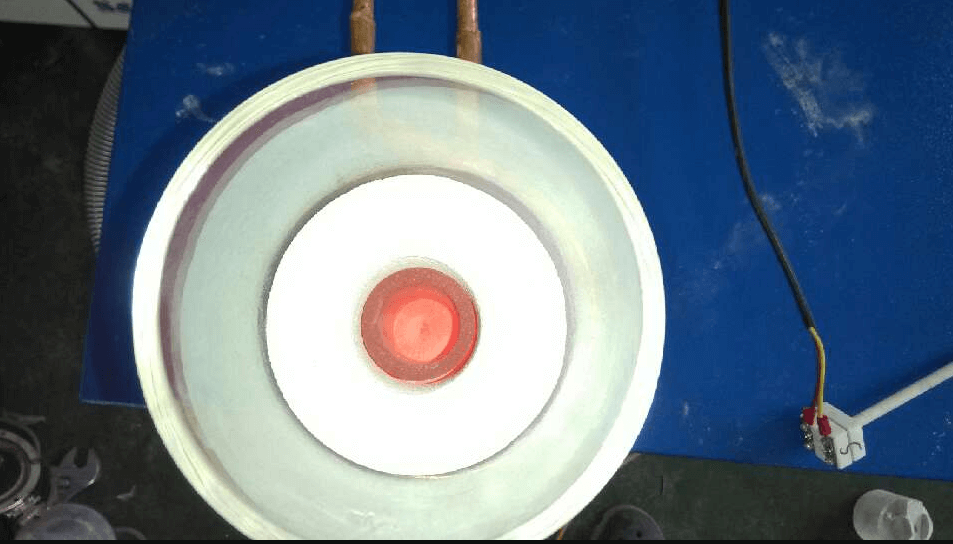

Induction heating furnace:

using IGBT power module and variable flow control technology, easy to operate, easy to maintain, have the water pressure and over temperature protection.

|

High frequency induction heating furnace

|

working voltage: 220VAC, single phase working current: 2-52a (transformer transformer current) (requires 63A air switch) output power: 25KW output frequency: 30-80khz (adjustable) cycle ratio: 100% copper coil size: 170mm (OD) x 160mm (ID) x 90mm (H) protection system: automatic water pressure, overheat, overpower protection refractory materials: equipped with multi-layer graphite fiber layer and alumina fiber layer to support graphite crucible and prevent thermal radiation |

|

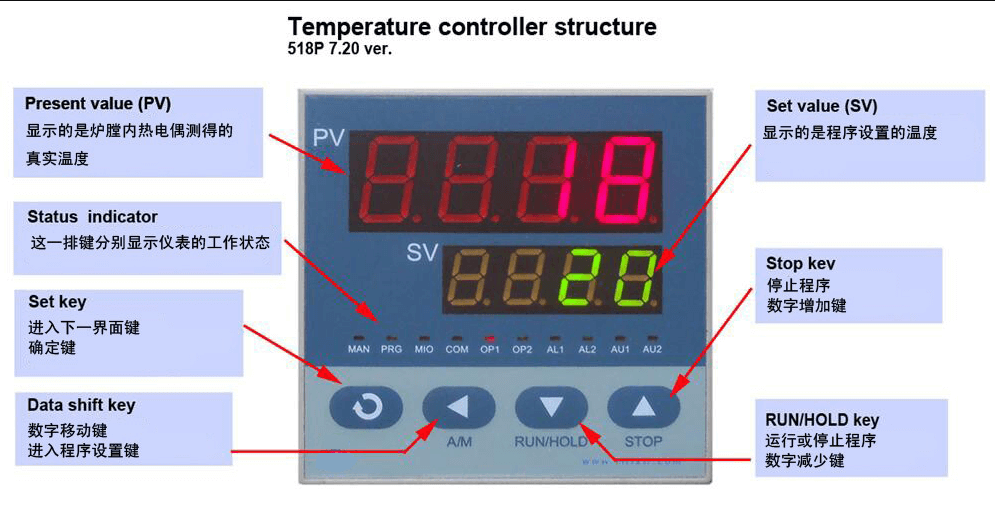

Temperature control system and thermocouple

|

Working voltage: 208-240vac, single phase. PID control can be used to manually adjust the current output. The equipment is overheat and broken. · Temperature control accuracy: + / -5 (thermocouple probe located at the top of the sample) The highest working temperature: 2200 ℃ (working time is less than 30 min) Long working temperature: 200 pieces C ~ 2100 Maximum heating rate: The equipment is overheat and broken Temperature control accuracy: + / -5 (thermocouple probe located at the top of the sample) The highest working temperature: 2200 ℃ (working time is less than 30 min) Long working temperature: 200 pieces C ~ 2100 Maximum heating rate: Temperature control accuracy: + / -5 (thermocouple probe located at the top of the sample) The highest working temperature: 2200 ℃ (working time is less than 30 min) Long working temperature: 200 pieces C ~ 2100 Maximum heating rate:

10ºC/second (200ºC-1200ºC) |

|

Graphite crucible and firebrick

|

The instrument is equipped with a high-purity graphite crucible: 59mm(OD)×49mm(ID)×95mm Maximum capacity: the sample size shall be 2/3 of the volume of graphite crucible Instruments equipped with resistance to 2500 ℃ in the high purity graphite fiber felt and the alumina fiber felt can be resistant to 1700 degrees, Used for lifting graphite and preventing thermal radiation effect flange sealing |

|

Seal flange and quartz tube

|

(when the temperature is above 1700 degrees) flange adopts water cooled flange and is installed with quartz observation port for the light of the infrared thermometer.The flange is fitted with a stainless steel needle valve.(infrared thermometer) Bottom flange: install stainless steel needle valve and KF25 interface (connected with vacuum pump) quartz tube size 150mm (OD) x142mm (ID) x 300mm (L) |

|

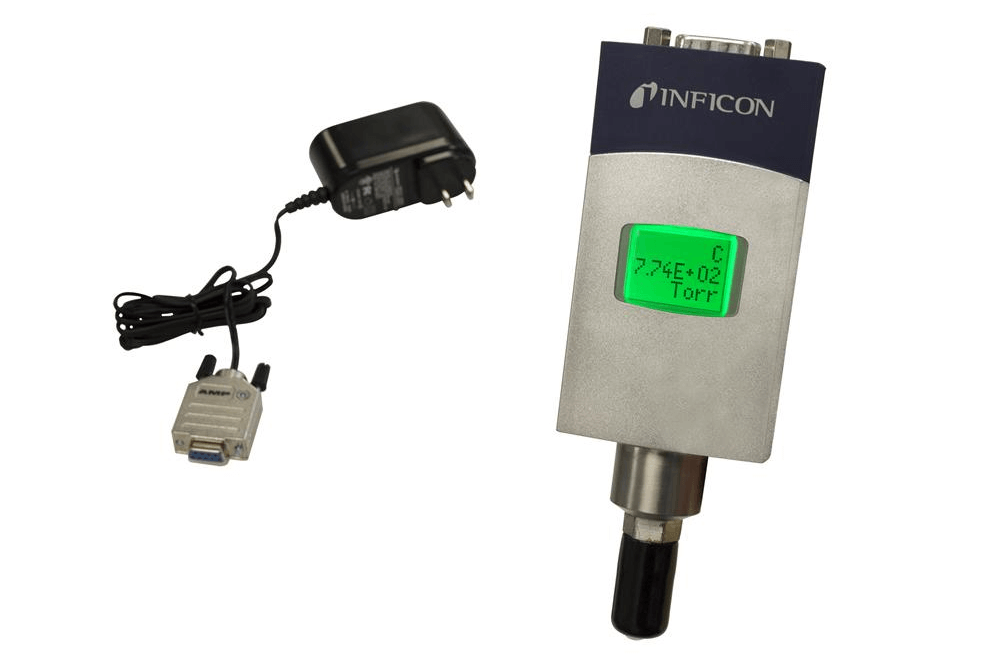

vacuum gauge

|

The entire vacuum degree is free of deviation, accuracy and sensitivity. |

|

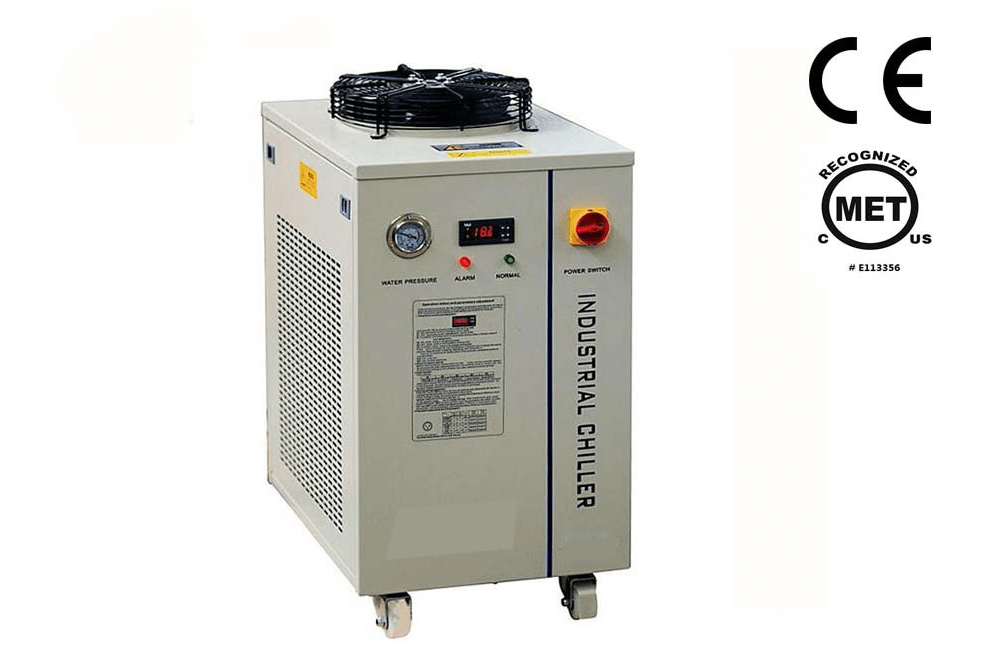

Circulating water cooler

|

Temperature range: 5-30 ℃ Cooling water flow rate: 16L/min Water tank: 12L, made of stainless steel Working voltage: ac208-240v, single phase Model: CW5300 |

|

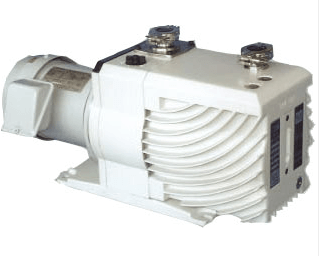

Vacuum pump

|

The instrument is equipped with a double - rotating mechanical pump vrd-8 Extraction rate: 8 m3 / h, limit vacuum degree 6X10 e-2 Pa Working voltage: ac208-240v, single phase Maximum power: 375W In order to obtain a higher vacuum degree to achieve better smelting effect, the vortex molecular pump can be selected and the vacuum degree can reach 10e-4pa |

|

product size |

induction melting furnace: Main Volume (CM):55.5L×25.2L×46.2H extension set (CM):36×26×36 Circulating water cooler:460mm(L) x 480mm(W) x 763mm(H) Moving frame size:600mm(L) x 1000mm(W) x 600mm(H) |

Previous :

Lab VIF Vacuum Melting Furnace

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com