- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Supercapacitor Assembly Equipment

- Dry Electrode Assembly Equipment

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Cylinder Cell Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- Customized Electrode

Automatic Electrode Making Ultrasonic Tab Welding Machine

Model Number:

TMAX-ZP-100Compliance:

CE certificateWarranty:

One years limited warranty with lifetime technical supportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 days

Automatic Electrode Making Ultrasonic Tab Welding Machine

1、 Equipment introduction

The function of this automatic electrode making machine includes: feeding electrode, welding electrode, sticking tape on the electrode, sticking tape on the blank coating boundary , cutting electrode, rolled electrode discharge, etc.

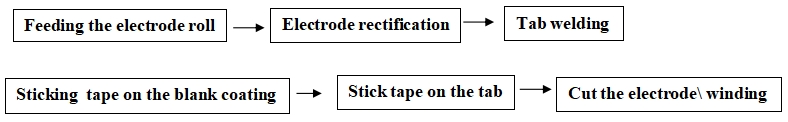

1.1 Machine operation process:

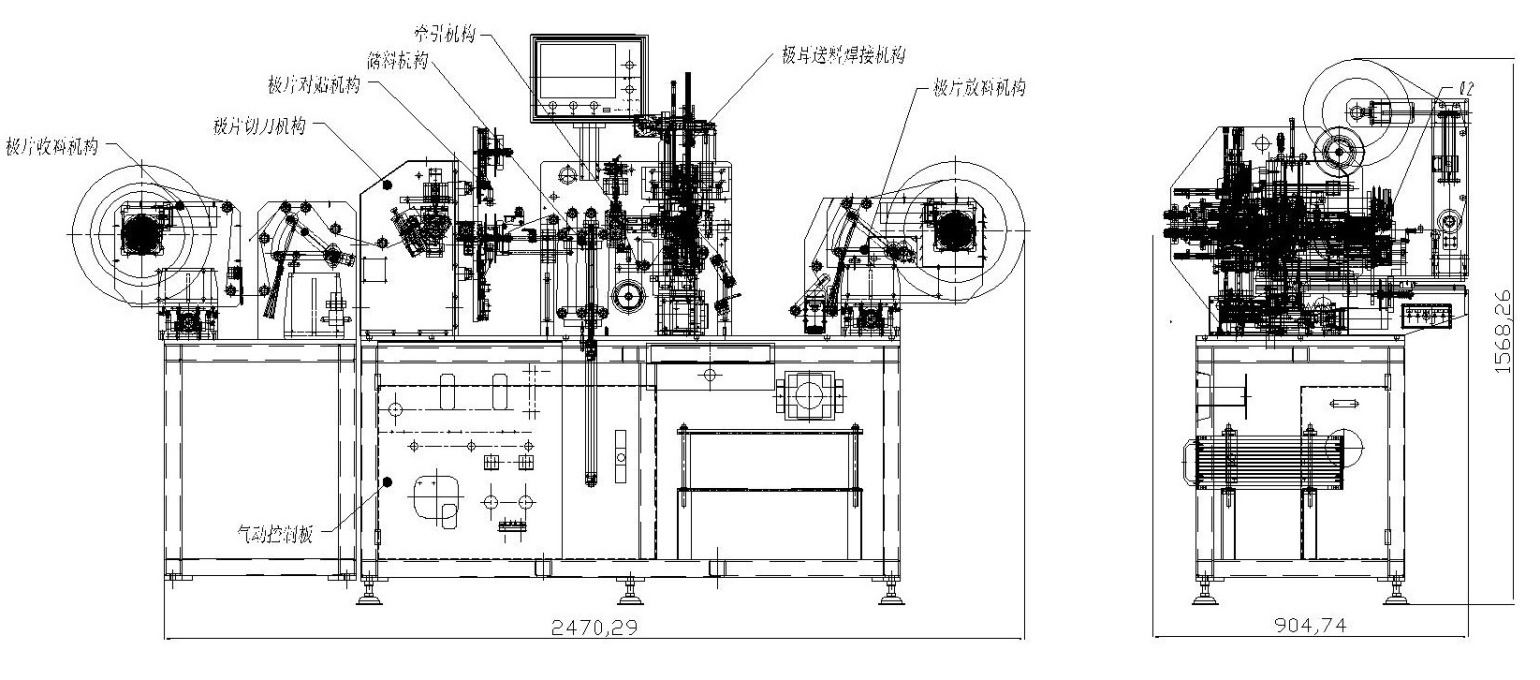

1.2 Main components of the machine:

1. Rack mechanism:

It includes rack body, large plate (mounting plate) and human-machine interface components.

(a) The main body of the rack supports and fixes the whole equipment;

(b) Large plate (mounting plate) provides unified installation plane and installation benchmark for other systems;

(c) The operation of human-machine interface component control equipment;

2. Electrode unwinding and rectifying mechanism:

(a) The electrode coil is fixed by a 3-inch pneumatic shaft, which is driven by a servo motor for active unwinding, and the cylinder tension is controlled by a precise pressure regulating valve, so that the electrode tension is constant;

(b) The deviation rectifying servo motor drives the screw pair to automatically adjust the coil position, so that the position of the outer edge of the electrode is stable. Electrode conveying and positioning are completed by electrode conveying roller device and optical fiber detection and positioning mechanism, and each conveying length is controlled by servo motor and optical fiber detection.

3. Electrode supply and cut-off mechanism:

Electrode unwinding and straightening and conveying device: the electrode is a coil feeding mode, and the unwinding tension is controlled by the active unwinding mechanism. After unwinding, the electrode is leveled by the leveling mechanism. The electrode conveying is driven by the servo motor ball screw and cut to a fixed length to ensure the accuracy of the electrode conveying length. The electrode conveying device is designed by module, through linear guide rail and locking device, The adjustment model is convenient and fast, the accuracy is stable, the exposed length of the electrode is guaranteed, and the pitch error of the electrode is distributed inside the electrode. Before welding, the electrode shall be aligned on both sides of the metal to ensure the position accuracy and welding accuracy of the negative electrode.

4. Electrode welding mechanism:

(a) Equipped with Kepu / gold and energy ultrasonic welding machine. Automatic welding according to coating position, adjustable welding time, pressure, stroke and speed;

(b) Equipped with anti sticking die device, with the function of detecting the bad coated electrode, the bad electrode is not welded.

5. Electrode traction mechanism:

The servo motor drives the fixed length wheel to pull the electrode, with large wrap angle design and electrode pressing roller.

6. Electrode storage mechanism:

The transition roller is fixed on the slide of the vertical linear guide rail to store materials for the electrode, and the tension is constant. When the transition roller reaches the limit position, it will automatically return to normal production.

7. Protective tape sticking mechanism:

According to the coating position, the protective tape is automatically pasted; the unique gluing method is adopted, with high precision, adjustable length, stable structure and convenient adjustment. It has the function of vacuum alarm when the adhesive mechanism does not absorb the adhesive paper. It has two groups of gluing mechanism, and can stick four layers of adhesive paper at the same time. The gluing mechanism can be opened and used selectively.

8. Electrode dedusting device:

Use brush to remove the dust on the surface of the electrode, with a vacuum pipe interface.

9. Electrode collection mechanism:

(a) Cut the welded and taped electrodes into pieces according to the coating requirements, and then use the automatic material collection platform to collect the rolled electrode.

(b) The electrode cutting method is used for material collection, and the interface and position of the winding method are reserved.

Note:

When the type of electrode is changed, the special parts shall be replaced for correspondence

1. According to the coating requirements, the automatic cutting of the electrode has a fixed length cutting function (cutting two times). (first and last two cuts)

2. Tab is cut at a fixed length and automatically welded to the electrode. One tab can be welded 1-2 times along the width direction of the electrode(optional); (this function is required) (the minimum distance between two times of welding is 4mm).

3. Two protective tapes can be pasted at the head of the positive electrode, four at the tail, two at the negative electrode, and two at the tail to meet different process requirements of customers; (the left and right dislocation of the tape is less than 0.5mm).

2、 Process technical requirements

1. Incoming material requirements

|

|

Number of reels |

Width (mm) |

Thickness (μm) |

Length (mm) |

Max. O.D |

Coil core I.D |

|

Positive electrode |

1 |

28-100 |

60~300 |

300-2000 |

φ400 |

φ76.2 |

|

Positive tab |

1 |

3-6 |

80~150 |

35-80 |

φ400 |

φ76.2 |

|

Positive tab tape |

1 |

6-25 |

16~100 |

- |

φ150 |

φ76.2 |

|

Positive protection tape |

2 |

6-25 |

16~100 |

28-100 |

φ150 |

φ76.2 |

|

Negative electrode |

1 |

28-100 |

60~300 |

300-2200 |

φ400 |

φ76.2 |

|

Negative tab |

2 |

3-6 |

80~150 |

40-80 |

φ400 |

φ76.2 |

|

Negative protection tape |

2 |

6-25 |

16~100 |

28-100 |

φ150 |

φ76.2 |

1.1. Applicable material specifications

Remarks:

1. Intermittent error of electrode coating: ± 2mm

2. Positive and negative alignment error of electrode blank: ± 2mm

3. The serpentine bending error of single electrode: 0.2mm/500mm. electrode ± 0.5mm, tab ± 0.2mm.

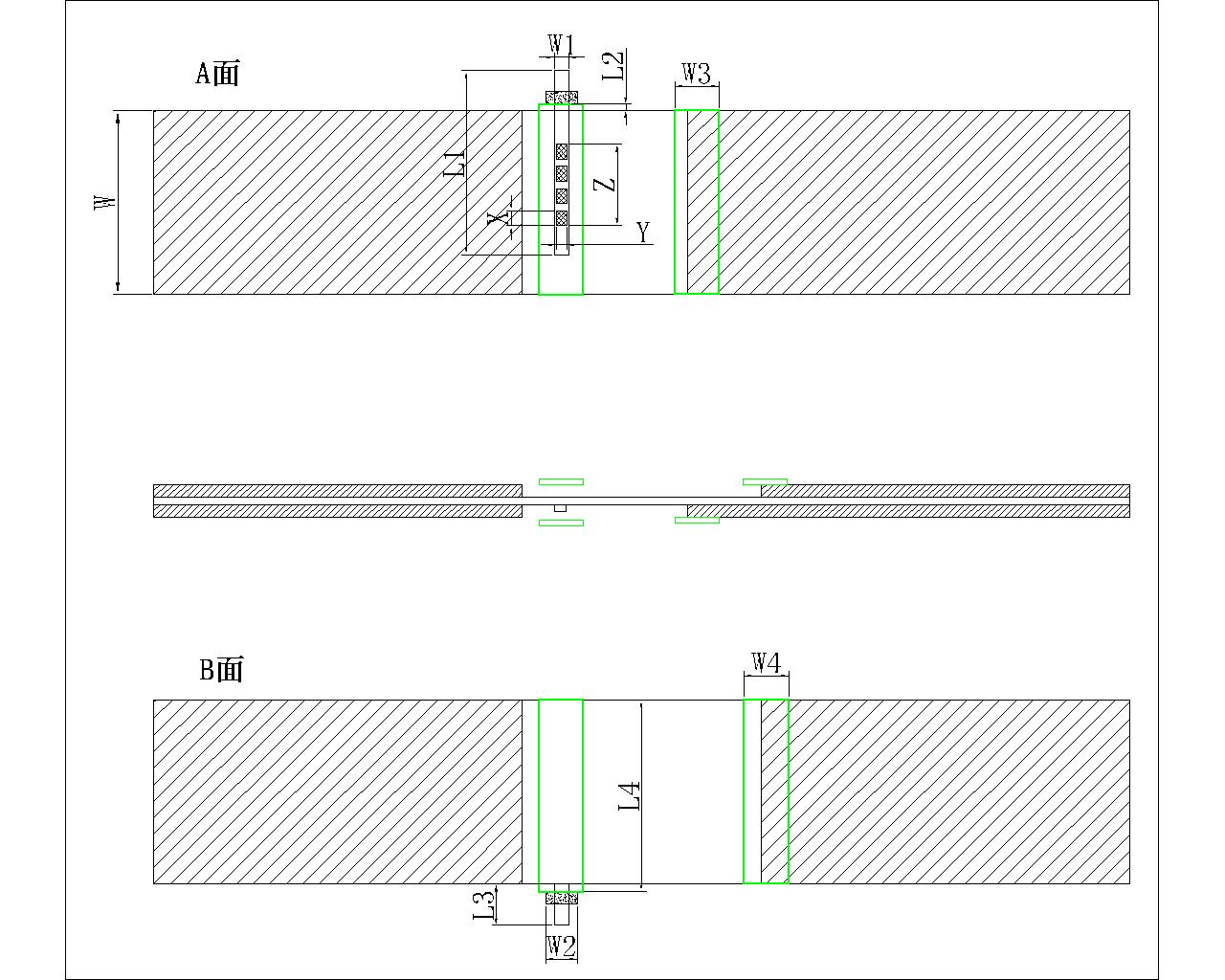

2、Process dimension table

|

Parameter |

Size range(mm) |

Acceptance value(mm) |

|

Electrode width (W) |

28-100 |

- |

|

Tab width (W1) |

3-6 |

- |

|

Width of tab tape (W3.W4) |

6-25 |

- |

|

Tab length (L1) |

35-80 |

±0.5 |

|

Tape on edge of electrode (L2) |

0.5-1 |

±0.2 |

|

Positive welding area (X × Y × Z) |

3×25 |

- |

|

Negative welding area (X × Y × Z) |

3×4×25 |

- |

|

Exposed length of tab(L3) |

4-30 |

±0.2 |

|

Length of tab tape (L4) |

28-100 |

±0.2 |

|

Welding deviation of tab |

±1° |

- |

|

Total length of electrode |

300-2600 |

±0.5 |

|

Welding position and cutting position error |

±0.25 |

|

2.1 cutting burr of electrode: cutting transverse burr ≤ 0.015mm, cutting longitudinal burr ≤ 0.01mm;

After cutting, the edge burr of the electrode must be ≤ 0.01mm.

2.2. There shall be no obvious indentation and scratch on the electrode.

2.3. The welding tension of electrode shall be no less than 15N (or as required by relevant documents), and the amount of foil attached to the welding electrode shall be no less than 70%.

2.4 service life of electrode cutter: 200000 times of grinding, and the number of times of grinding ≥ 5.

2.5 service life of welding head: 1 million times for positive electrode and 150000-200000 times for negative electrode (double-sided) are related to electrode material and thickness.

2.6. Welding machine brand, power and model: Kepu \ jinhneng welding machine, P = 700W, jyhj-40.

2.7 after pasting the adhesive tape, the adhesive tape and the electrode shall be free of wrinkles, and the adhesive tape shall be free of wrinkles and obvious bubbles.

2.8. It has the alarm function of electrode not welded.

2.9. electrode tension adjustment: range: 100-1500gf precision: ± 0.5%; setting mode: manual precise pressure regulating valve adjustment.

2.10. Production speed: 30-40 PCS / min (take: 2 layers of glue, paste to paste, length: 650mm, cutting type as an example)

3、 Function selection table

3.1 Positive electrode: (applied to cylindrical battery core)

|

Tab type |

Tab without tape wrapped |

Tab wrapped with tape |

Long and short tab |

|

|

|

|

√ |

|

|

||

|

Electrode sticking |

No tape |

Two tapes |

Four tapes |

Six tapes |

|

|

|

√ |

|

|

||

|

Sticking method |

Aligning sticking |

Dislocation sticking |

|||

|

2 |

|

||||

|

Rewinding method |

Winding type |

Cutting type |

Cutting + collection |

Other ways |

|

|

√ |

|

|

|

||

|

Auxiliary device |

Tab knurling |

Unwinding dust removal |

Dust removal after welding |

Electrode flapping |

|

|

|

√ |

|

|

||

3.2 Negative electrode

|

Tab type |

Tab without tape wrapped |

Tab wrapped with tape |

Long and short tab |

|

|

|

|

√ |

|

|

||

|

Electrode sticking |

No tape |

Two tapes |

Four tapes |

Six tapes |

|

|

|

√ |

|

|

||

|

Sticking method |

Aligning sticking |

Dislocation sticking |

|||

|

2 |

|

||||

|

Rewinding method |

Winding type |

Cutting type |

Cutting + collection |

Other ways |

|

|

√ |

|

|

|

||

|

Auxiliary device |

Tab knurling |

Unwinding dust removal |

Dust removal after welding |

Electrode flapping |

|

|

|

√ |

|

|

||

4、 Equipment Overview

4.1 electrical equipment: single-phase 220V / 20A / 50Hz, two tapes power: 4.0kW; four tapes power: 4.5kW; six tapes power: 4.8kW.

4.2 compressed air: above 0.5MPa, flow rate is required to be 120L / min (drying is required).

4.3 vacuum: equipped with vacuum generator.

4.4 weight: 1000 kg (floor load of the buyer's workshop: 500kg / ㎡.)

4.5 overall structure and overall dimension: (excluding electrode receiving)

Two tapes: (about) 1950mm long; 1100mm wide; 1650mm high;

Four tapes: (about) 2100mm long; 1100mm wide; 1650mm high;

Six tapes: (about) are 2400mm long, 1100mm wide and 1650mm high.

4.6 others: room temperature 10-30 ℃ / humidity 30-70%, no condensation, no combustible or corrosive gas.

5.Device configuration and standards

5.1 the equipment is equipped with PLC, communication function module with external system and touch screen. The operation interface is Chinese (including part of English). The equipment is equipped with leakage protector. Sliding valve is installed at the pressure reducing valve to facilitate the disconnection of air source.

5.2 aluminum and stainless steel or carbon steel are preferred for corrosion protection.

5.3 the design shall meet the general safety requirements, and the electrical equipment shall be well grounded.

5.4 appearance color of equipment: made according to the buyer's color board. And it needs to be made with the standard color plate provided by the buyer, and the newly made color template can be made in large quantities only after being confirmed by the buyer.

5.5 noise ≤ 70 dB measured 10 mm away from the outer wall of the machine (except for material reasons, such as the sound of tape peeling).

5.6 the equipment shall meet the safety standards of relevant national equipment.

5.7 attached with the machine are Chinese operation instructions, instructions of main components, list of vulnerable parts, accessories of specification parts, etc.

5.8 the equipment shall be attached with the list of vulnerable parts, warranty card and other information.

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat 13506084915

Wechat 13506084915