- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Supercapacitor Assembly Equipment

- Dry Electrode Assembly Equipment

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Cylinder Cell Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- Customized Electrode

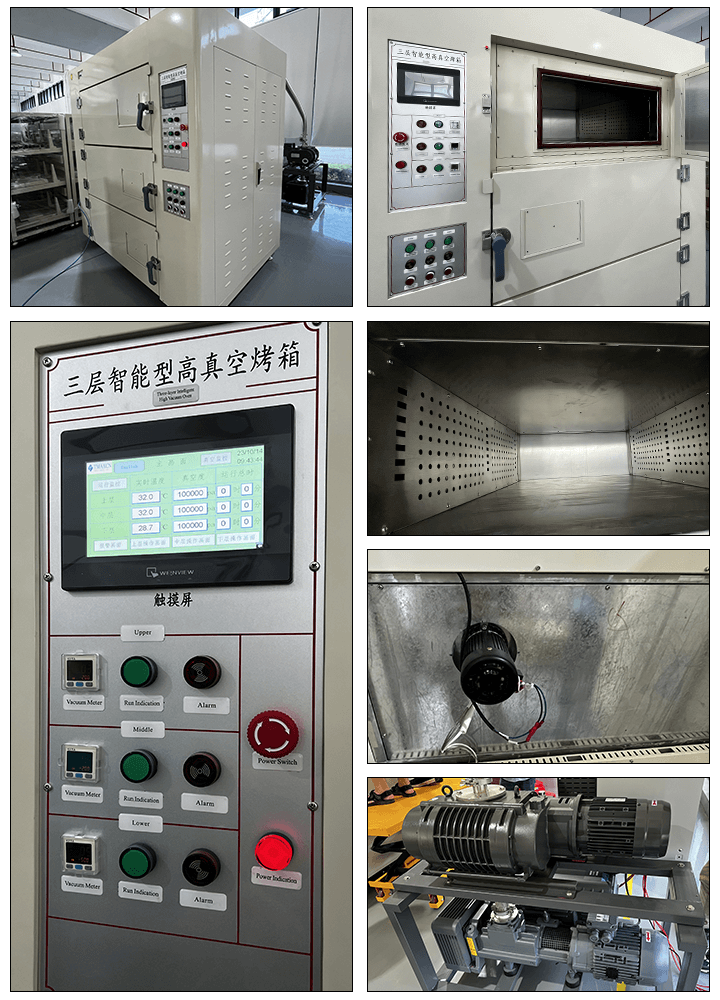

Three-layer Automatic Vacuum Drying Oven For Battery Materials Baking

Model Number:

TMAX-310-AType:

Vacuum Drying OvenCompliance:

CE certificateWarranty:

2 year limited warranty with lifetime supportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 days

Three-layer Automatic Vacuum Drying Oven For Battery Materials Baking

1.Application Range of the Oven:

Suitable for drying lithium-ion battery electrodes,cells,and batteries prior to electrolyte injection.

2.Configuration:

A. Cabinet:Utilizes 3.0mm imported 304 stainless steel with reinforcement made from the same material.

B. Frame:Made from 1.5mm and 2.0mm quality cold-rolled steel plates,featuring a double-layer insulation construction including aluminum silicate,aluminum foil cotton,and soundproof cotton.

C. Control System:Consists of PLC,touchscreen,pressure sensor,high vacuum baffle valve,solid state relays,temperature controllers,solenoid valve assemblies,and more.

D. Hardware:Comprises doors,rear covers,vacuum pipes,and other stamped parts.

3.Machine Features:

A. Dual-layer insulation design,maintaining exterior temperatures below 45 degrees Celsius(excluding the glass door).

B. High vacuum pneumatic baffle valve,allowing triple-layer isolation and individual control.

C. Touchscreen interface for display and automation cycle control;also allows for maintaining vacuum pressure after the last step and displays safety temperature digitally.

D. Flexible double-glazed door,providing triple-layer pressure testing with overpressure protection.

E. Features multi-positional over-temperature protection for enhanced safety and precision in temperature control,effectively preventing temperature runaways.

F. The control screen features a user-friendly touchscreen interface for centralized operation;the PLC-based program controller ensures stable and reliable functioning.

G. Independent control for each layer of the oven,allowing for the setting of total bake time,cycle time,vacuum time,and drying time;executing automatic baking programs with the push of an auto button and shutting down automatically once the baking time is up.If the temperature surpasses the safety threshold,an alarm will activate,a red indicator light will illuminate,and the heating will stop while displaying an alarm message onscreen.

H. Automatic stop feature for inflation of dry gas into the chamber at any set value between-0.1Mpa and-0.02Mpa.

I. Regular work mode provides fault alert alarms and descriptions of fault reasons on-screen.

J. The vacuum pipes are designed to be corrosion-resistant.

K. Program interlock system to prevent gas crossover between layers.

3. Technical parameters

|

No. |

Item |

Technical Parameters |

|

1 |

Heating Principle |

Three-layer individual independent heating |

|

2 |

Power Supply |

380V 50HZ 9KW |

|

3 |

Gas Source |

Dry gas 0.1-0.2Mpa / Vacuum -0.095--0.1Mpa / Compressed gas 0.4-0.5Mpa |

|

4 |

Temperature |

Room temperature to 150℃ |

|

5 |

Degree of Vacuum |

When vacuum reaches between -0.1 and -0.09Mpa, digital display shows 24-hour pressure maintenance ≥95% |

|

6 |

Display Error |

Set value and stable display value ≤±1℃ |

|

7 |

Insulation Performance |

Outer wall temperature does not exceed 45 degrees Celsius (except for the glass door) |

|

8 |

Temperature Uniformity |

Within 50MM from inner cavity walls: ≤±4℃ under vacuum and ≤±3℃ under normal pressure |

|

9 |

Temperature Interference |

≤25℃ (Neighboring layers heating within 100 degrees, not exceeding room temperature by more than 25 degrees) |

|

10 |

Response Speed |

Display reaches set value within 30 minutes, core temperature stabilization time of empty load 60-100 minutes |

|

11 |

Chamber Dimensions |

Height 330mm × Width 830mm × Depth 800mm × 3 |

|

12 |

Overall Dimensions |

Height 1970mm × Width 1250mm × Depth 1100mm |

4. Electrical configuration:

|

No. |

Name |

Specification Description |

|

1 |

PLC |

Zhongshan Zhida |

|

2 |

Touch Screen |

7-inch LCD Kunlun Tongtai |

|

3 |

Temperature Controller |

Digital Display Smart Thermostat/Microcomputer PID Automatic Calculation |

|

4 |

Temperature Control Mode |

PID+SSR (Silicon Controlled Rectifier), Shanghai Yatai |

|

5 |

Over-Temperature Protection |

Shanghai Yatai Temperature Controller |

|

6 |

Temperature Sensor |

Type K Thermocouple |

|

7 |

Vacuum Gauge |

Digital Vacuum Gauge/-101.0-101.0kPa General Type for Positive and Negative Pressure, Taiwan Jingdeng |

|

8 |

Vacuum Valve/Nitrogen Valve |

High Vacuum Baffle Valve |

|

9 |

Alarm |

Audio and Light Alarm |

|

10 |

Heating Tube |

Great Wall Electric Heating |

|

11 |

Control Method |

Each chamber works independently, the heating, vacuuming, and nitrogen-filling operation modes are PLC automatic cyclical; the operations for each working segment are set through the touch screen. |

5. Installation Requirements

5.1 Space Clearance

- Minimum distance from the front of the oven to the wall: 1500mm

- Minimum clearance on the left, right, and rear sides: 500mm

The user must provide an independent power switch and handle the connection of external power to the equipment.

5.2 Site Conditions for Installation (Provided by Party A):

5.2.1 Power Supply: Three-phase five-wire system, Frequency: 50±1Hz;

5.2.2 Vacuum:Pressure at -0.1MPA, vacuum tube diameter DN20

5.2.3 Nitrogen:Pressure ranging from 0.1 to 0.2MPA, nitrogen pipeline diameter φ12 air pipe

5.2.4 Compressed Air: Pressure between 0.4 to 0.6MPA, diameter φ8 air pipe

5.4 Energy Consumption

5.4.1 Maximum Consumption: ≤9kw/hour

5.4.2 Average Consumption:** ≤2.5kw/hour

5.5 Environmental Requirements

5.5.1 Temperature & Humidity:** Temperature between -5 to 35℃, Humidity ≤40%

5.5.2 Surrounding Area: Must be free from flammable and explosive gases, liquids, or solids.

5.5.3 Oven Usage:Baking of flammable materials, combustible gases, or explosives inside the oven is strictly prohibited.

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat 13506084915

Wechat 13506084915