- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

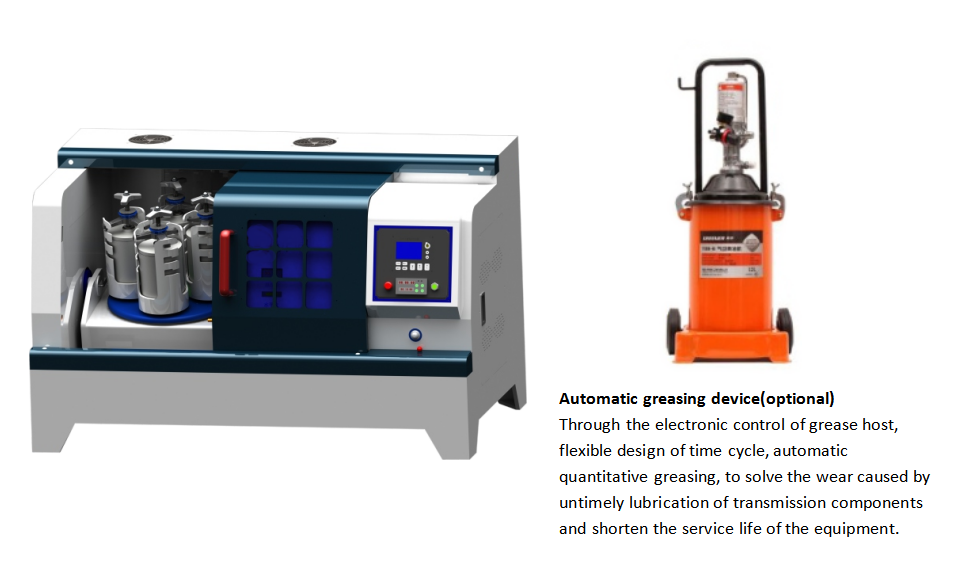

0.4L-40L 360C Degree Full Directional Turning Comprehensive Planetary Ball Mill Turnover Grinding Machine

Model Number:

TMAX-OPBMType:

Planetary Ball Mill MachineCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

0.4L-40L 360C Degree Full Directional Turning Comprehensive Planetary Ball Mill Turnover Grinding Machine

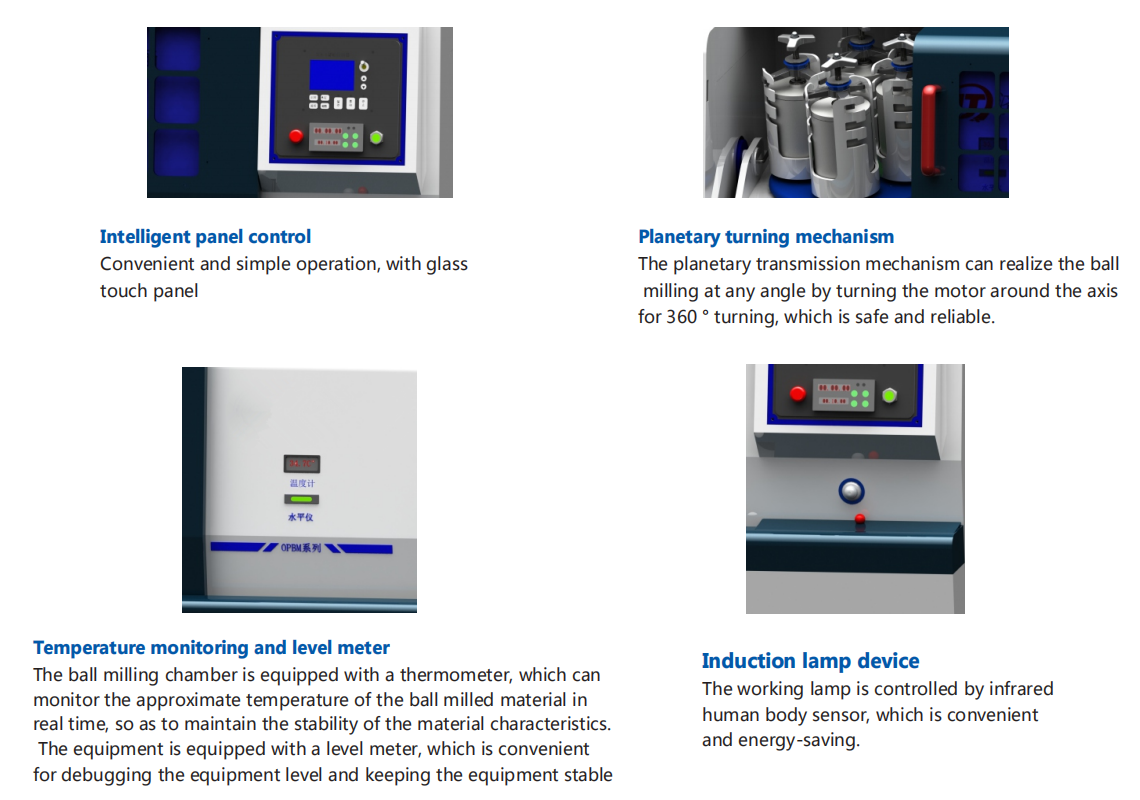

The comprehensive planetary ball mill is based on the vertical planetary mill, adding the turning function of the planetary transmission mechanism. While the planetary plate and the materials and grinding balls in the ball mill can do the planetary movement, they can also do the 360 ° turning in a fixed space, so as to realize the multi-dimensional and multi-directional movement of the grinding balls and materials in the ball mill, improve the degree of disordered movement of the grinding balls and materials, and complete There is no dead angle for grinding materials in the grinding tank, which makes the ground materials more uniform, and solves the problems of sinking and sticking of some materials.

Features

The equipment is light and easy to operate. The shell is made of high-precision laser cutting, CNC bending, elegant and high-end stable. The planetary disk and structural components are processed by CNC processing technology, and the nitriding metal heat treatment technology ensures the wear-resisting of the rotating shaft and prevents the shaft from breaking. The transmission gear is made of high-temperature wear-resistant non-metal and metal combination precision gear, lubricated by grease It can be equipped with our company's automatic greasing device, which can flexibly set how long the automatic quantitative oiling can take. It can solve the wear caused by the untimely lubrication of the transmission components, shorten the service life of the equipment, and ensure the smooth and quiet operation of the equipment at high speed.

Specifications

|

Transmission mode |

Gear drive |

||||||

|

Maximum sample loading |

2/3 of the capacity of the ball mill |

||||||

|

Volume of ball mill |

0.05L-10L per tank, total volume 0.2l-40l |

||||||

|

Feed size |

Soil material≤10mm, other materials≤3mm |

||||||

|

Discharge particle size |

Up to 0.1um minimum |

||||||

|

Speed regulation mode |

Stepless speed regulation of frequency converter |

||||||

|

Model |

Volume (L) |

Applicable jar volume |

Power(kW) |

Runing time(min) |

Revolution speed(rpm) |

Rotation speed(rpm) |

Weight(kg) |

|

OPBM-0.4 |

0.4 |

50-100ml |

0.25 |

1-9999 |

47-465 |

94-930 |

140 |

|

OPBM-1 |

1 |

50-250ml |

0.75 |

1-9999 |

35-370 |

70-740 |

280 |

|

OPBM-2 |

2 |

50-500ml |

0.75 |

1-9999 |

35-370 |

70-740 |

280 |

|

OPBM-4 |

4 |

250-1000ml |

0.75 |

1-9999 |

35-370 |

70-740 |

285 |

|

OPBM-6 |

6 |

1-1.5L |

0.75 |

1-9999 |

35-370 |

70-740 |

290 |

|

OPBM-8 |

8 |

1-2L |

1.5 |

1-9999 |

35-320 |

70-640 |

345 |

|

OPBM-10 |

10 |

1-2.5L |

1.5 |

1-9999 |

35-320 |

70-640 |

345 |

|

OPBM-12 |

12 |

1-3L |

1.5 |

1-9999 |

35-320 |

70-640 |

350 |

|

OPBM-16 |

16 |

2-4L |

3 |

1-9999 |

30-255 |

60-510 |

400 |

|

OPBM-20 |

20 |

2-5L |

4 |

1-9999 |

25-215 |

50-430 |

710 |

|

OPBM-40 |

40 |

5-10L |

5.5 |

1-9999 |

20-195 |

40-390 |

1000 |

Model selection guidance

Selection of size of planetary ball mill:

Planetary ball mill style and special function configuration options:

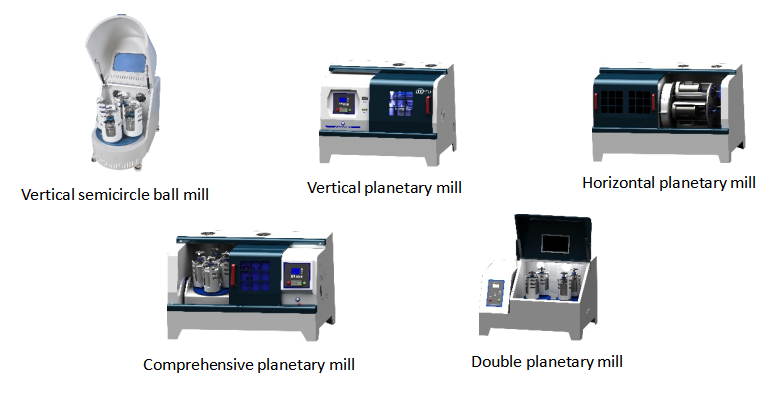

Reference table for selection of planetary ball mill style and special function configuration

|

Model selection of planetary ball mill |

Nature of abrasive material |

|

Vertical planetary mill |

Grinding of general materials, no special requirements |

|

Comprehensive planetary mill or horizontal planetary mill |

The material is easy to sink and bind |

|

Double planetary mill |

Ultra high speed and ultra-fine grinding are required |

|

With air cooling device or liquid nitrogen device |

The grinding process is hot and needs to be cooled |

|

Equipped with vacuum ball milling tank |

Easy to oxidize, requiring vacuum environment or atmosphere protection |

|

With heating device |

High temperature grinding required |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com