- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

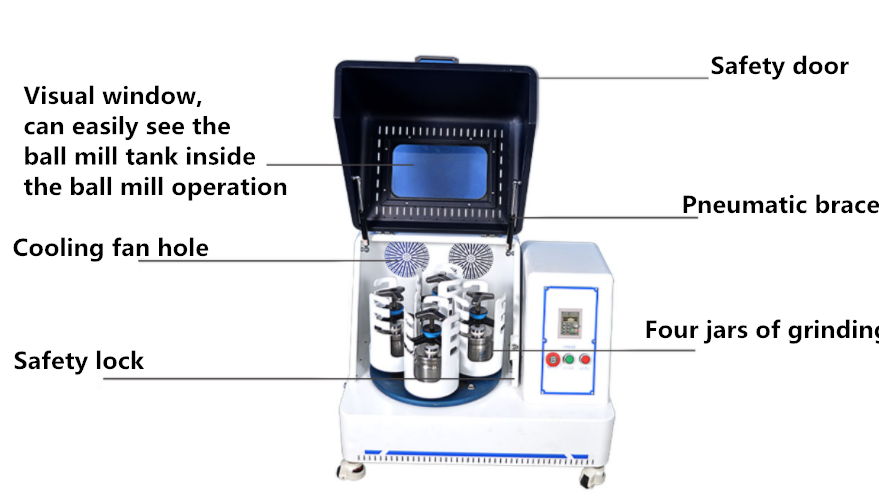

1-12L Lab Small Square Vertical Planetary Ball Mill

Model Number:

TMAX-PBM-LSType:

Planetary Ball Mill MachineInput Power:

0.37KWDimension(L*W*H):

570*300*450mmMax. Loading Capacity:

0.2L-0.4LNet Weight:

35KGCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

1-12L Lab Small Square Vertical Planetary Ball Mill

Frequency conversion control

Ideal speed can be set according to the experimental requirements, high speed accuracy, frequency converter with undervoltage, over current, overload protection, optional intelligent panel, easy operation.

Planetary gear

Integral casting molding main plate, with manual anti-loose staring device (optional self-locking type), delicate and beautiful; Stable speed, high efficiency and good safety.

Cooling fan hole

The equipment runs at high speed, and the temperature inside the wall of the ball mill is effectively controlled by designing the reasonable layout of fan holes, so as to protect the normal ball grinding of materials and ensure the stability of the equipment.

Pneumatic brace

Constant support force, moderate resistance, easy to operate, safe.

A.The characteristics

Equipment through professional appearance modelling design, the shell is made of high precision mold stamping forming, generous and delicate, high-end sedate, planetary disc is made of casting forming, numerical control processing technology on structure component processing, transmission gear combination of high-temperature resistant non-metal and metal precision gear, metal heat treatment process of nitriding, can ensure abrasion resistance to prevent the broken shaft axis of rotation, to ensure that the equipment run time at a high speed It is stable and quiet, the grinding tank can be fixed at the same time, the operation is convenient, safe and reliable, the shell can match the color of the product, give the product new vitality, activate the new life of the product, in line with the international and domestic aesthetic needs, in line with ergonomics.

1. Fashion design

The equipment shell uses square design elements, high precision mold stamping forming, especially delicate.

2. Exquisite workmanship

Adopt numerical control processing technology, planetary disc integral casting molding, transmission gear selection of special material precision gear.

3. Grinding tank locking device

The crossbeam and nut of the locking device are all cast, easy to operate, safe and reliable. (Optional automatic locking device)

B. Parameter

Mode of transmission

Gear transmission

Mode of working

Two and four ball grinding jars work simultaneously

Mode of transmission

Two thirds of the volume of the ball mill jar

Ball mill tank volume

0.05-3L per jar, total volume 0.2-12L

Feed granularity

Soil material≤10mm, and other materials≤3mm

Granularity of discharge

Up to 1 micron

Mode of speed regulation

Infinitely adjustable-speed

Model

Volume

Configurable ball mill specifications

Qty

Configurable vacuum ball mill volume

Locking device (optional automatic)

PBM-LS-1

1

50-250ml

4

50-100ml

manual

PBM-LS-2

2

50-500ml

4

50-250ml

manual

PBM-LS-4

4

250-1000ml

4

50-500ml

manual

PBM-LS-6

6

1-1.5L

4

50-1000ml

manual

PBM-LS-8

8

1-2L

4

50-1500ml

manual

PBM-LS-10

10

1-2.5L

4

50-2000ml

manual

PBM-LS-12

12

1-3L

4

1L-2L

manual

Model

Power supply (single-phase)

Power(kw)

Total time to run the set(min)

Alternating positive and negative running time(min)

Adjustable speed

Revolution(rpm) Rotation(rpm)

PBM-LS-1

220V-50HZ

0.75

1-9999

1-9999

35-370

70-740

PBM-LS-2

220V-50HZ

0.75

1-9999

1-9999

35-370

70-740

PBM-LS-4

220V-50HZ

0.75

1-9999

1-9999

35-370

70-740

PBM-LS-6

220V-50HZ

0.75

1-9999

1-9999

35-370

70-740

PBM-LS-8

220V-50HZ

1.5

1-9999

1-9999

35-320

70-640

PBM-LS-10

220V-50HZ

1.5

1-9999

1-9999

35-320

70-640

PBM-LS-12

220V-50HZ

1.5

1-9999

1-9999

35-320

70-640

Model

Standard panel (optional intelligent, touch screen)

Lubrication way

Mode of speed regulation

Weight(kg)

Size(Length * width * height)

Noise≤db

PBM-LS-1

ordinary

grease

Frequency control

90

780*470*570

60±5

PBM-LS-2

ordinary

grease

Frequency control

93

780*470*570

60±5

PBM-LS-4

ordinary

grease

Frequency control

93

780*470*570

60±5

PBM-LS-6

ordinary

grease

Frequency control

95

780*470*570

60±5

PBM-LS-8

ordinary

grease

Frequency control

148

920*600*640

63±5

PBM-LS-10

ordinary

grease

Frequency control

150

920*600*640

63±5

PBM-LS-12

ordinary

grease

Frequency control

152

920*600*640

63±5

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com