- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

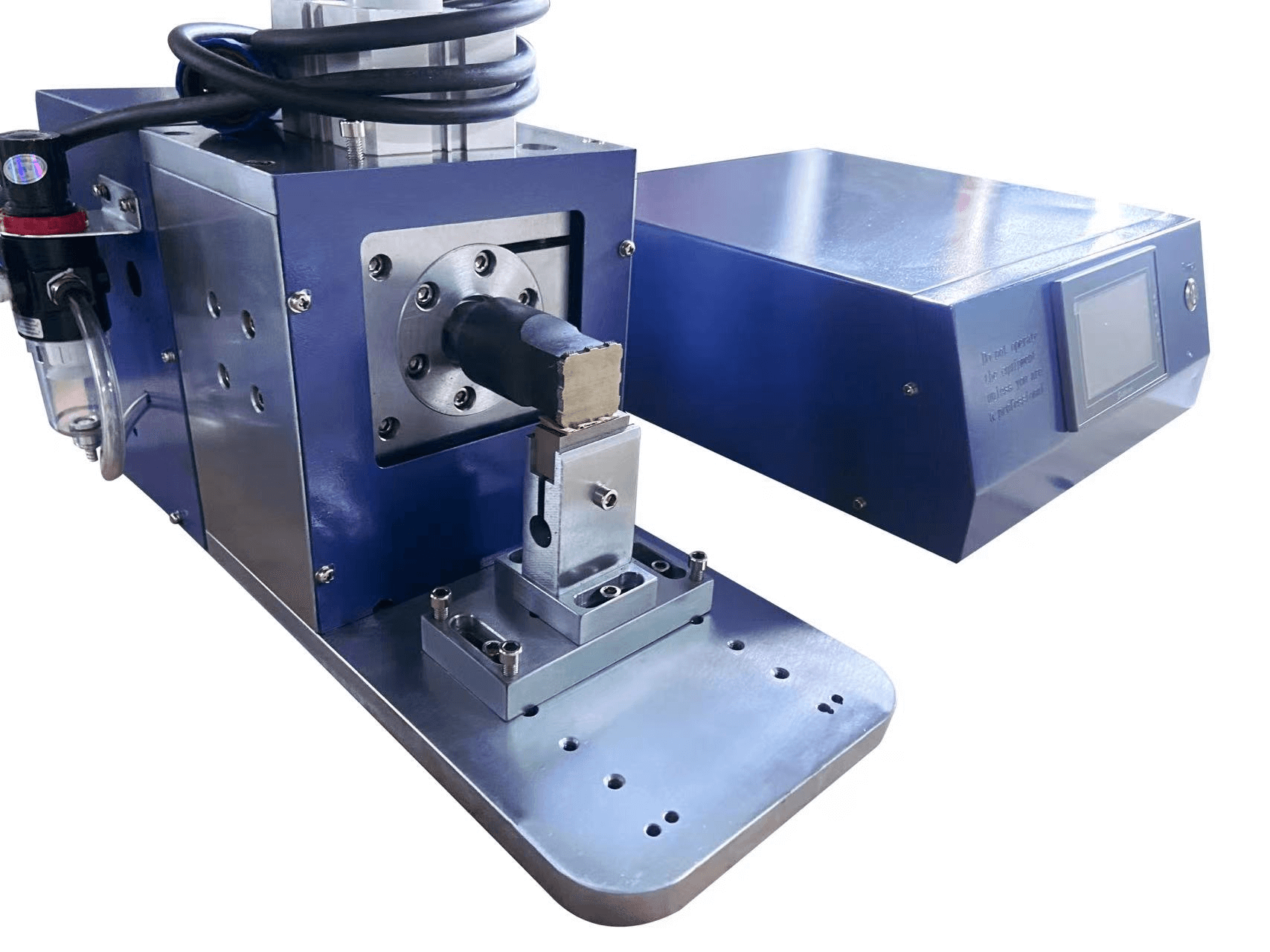

1000W 40KHz Ultrasonic Spot Welder Metal Foil Tab Welding Machine

Model Number:

TMAX-USW-1000WInput Power:

1000WCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

3 Days

1000W 40KHz Ultrasonic Spot Welder Metal Foil Tab Welding Machine

Functional characteristics

◆ Full digital ultrasonic system imported from Germany.

◆ The rising and falling speed of welding head can be adjusted and accurately controlled.

◆ Can accurately position the upper and lower positions of the welding structure.

◆ When the voltage fluctuates, the ultrasonic generator can automatically compensate the output voltage to ensure the stable output of the amplitude of the welding head segment.

◆ Accurate energy control mode can ensure the stability of each welding and reduce the influence of external factors.

◆ The welding head equipment adopts automatic frequency tracking, without manual frequency modulation. System startup self-test, no frequency modulation. After the welding head is replaced or repaired, the system does not need to be re-calibrated (other domestic companies need to collect the resonant frequency of the generator like an old radio).

◆ The application of IGBT power module and other excited oscillating circuit structure.

◆ When working, the frequency of the welding head and transducer will be offset with the change of temperature and load. The welding function automatically searches and tracks the resonant frequency of the transducer within the whole range to ensure that the transducer always works in a resonant state, ensuring the efficient operation of the equipment, and the welding is more stable and reliable.

◆ With a variety of welding modes such as energy and intelligent time, different welding modes adapt to different welding process requirements to achieve better welding results.

◆ 1%-100% amplitude can be set in the 0-100ms period, better adapt to different welding processes, so that you can run how you want the machine to run.

◆ Cloud services can be customized. Intelligent machine protection and fault alarm tips.

◆ Voltage protection system (power supply voltage range 215V ~ 238V); It does not affect the output power and working frequency of the machine during the automatic leveling voltage;

◆ Overload protection system; (3) Overcurrent protection; (4) Automatic compensation for power supply frequency instability; (5) Welding overload protection signal feedback.

◆ All gauges on the equipment use metric units.

◆ HD HMI touch screen, intuitive chart operation interface.

◆ More than 100 welding records can be checked.

Technical parameters

|

Item |

Name |

|

1. Base material |

|

|

1.1 Positive electrode |

|

|

1.1.1 Substrate (electrode sheet) material |

Aluminum foil |

|

1.1.2 Thickness of substrate (electrode sheet) |

0.012 |

|

1.1.3 Gasket (tab) material |

Aluminium electrode lug |

|

1.1.4 Wire |

About 0.1 |

|

1.2 Negative electrode |

|

|

1.2.1 Substrate(electrode sheet) material |

Copper foil |

|

1.2.2 Thickness of substrate (electrode sheet) |

0.08-0.012 |

|

1.2.3 Gasket (tab) material |

Nickel plated copper/nickel lugs |

|

1.2.4 Thickness of gasket (tab) |

About 0.1 |

|

2. cell |

|

|

2.1 Stacking process |

|

|

2.2 Maximum Number of layers (Acceptance criteria) |

Single or multi-layer welding. About 3 layers. |

|

2.3 Cell thickness |

|

|

3. Tab welding |

|

|

3.1 Tab welding method |

Transverse (customizable) |

|

3.2 Electrode welding capability |

Layer by layer, no black. |

|

3.3 Solder joint length |

20MM/35MM (customizable) |

|

3.4 Solder joint width |

3MM (customizable) |

|

3.5 Welding Time |

Within 1S |

|

3.6 Number of solder joints |

Design according to welding process |

|

3.7 Time adjustment range |

The value is adjustable from 0 to 60S |

|

3.8 Welding surface life |

≥ 100,000 times |

|

4. Welding head standard |

|

|

4.1 Welding head material |

Imported high speed steel |

|

4.2 Solder joint height |

0.3mm(according to different products, need to provide product process). |

|

4.3 Distribution of solder joints/lines |

Straight grain or rice grain on the welding head; Lower die mesh |

|

4.4 Height between the welding surface and the welding head |

> 5mm (adjusted according to product height) |

|

4.5 Length of welding head |

≥45mm |

|

4.6 Available welding surface of the welding head |

2 |

|

4.7 Welding head installation direction |

Transverse |

|

4.8 Adjustable amplitude range |

semi-cycle 20~40um |

|

5. Energy transducer |

|

|

5.1 Frequency difference between transducers |

≤400Hz |

|

5.2 Impedance difference between transducers |

≤8Ω |

|

5.3 Capacitance difference between transducers |

≤400PF |

|

5.4 Insulation resistance of transducer and housing |

≥30MΩ |

|

6. Ultrasonic generator |

|

|

6.1 Frequency control Mode |

The built-in frequency is adjustable |

|

6.2 Constant Amplitude function |

(constant amplitude) |

|

6.3 The amplitude is stepless and adjustable |

Stepless adjustable |

|

7. product |

|

|

7.1 Appearance |

No welding through, leakage, solid welding, layer by layer penetration |

|

8. Designed service life of equipment |

8 to 10 years |

Equipment parameter

|

Name |

Ultrasonic welding machine |

|

Model number |

TMAX-40K-1000W |

|

Supply voltage |

50 or 60Hz-/AC220V |

|

Screen |

Touch screen |

|

Digital system |

High stability |

|

frequency |

Automatic tracking |

|

power |

1000W |

|

Parameter saving function |

Yes |

|

Welding parameter call can be customized |

Yes |

|

Segmented power regulation |

Yes |

|

Welding time |

Adjustable (0.01s-2s) |

|

Welding mode |

single-point |

|

Preloading time |

Adjustable (0.02s-10s) |

|

Frequency calculation shows search range |

39.0000 to 40.5000 HZ |

|

Power adjustable |

800W.1000W |

|

Welding mode |

selectable |

|

Amplitude regulation |

Infinite amplitude regulation |

|

Case protection |

Intelligent protection and fault alarm tips |

|

Automatic frequency tracking |

Range ±40HZ |

|

Automatic temperature tracking |

Internal power tube 60° automatic protection |

|

EMI/EMC |

Strong anti-interference ability |

|

Input air source |

Air compressed gas 7-8BAT (kg/cm2) |

|

Maximum working pressure |

6 kg/cm2 |

|

Minimum working pressure |

0.3 kg/cm2 |

|

Intake joint |

Quick connector 8mm |

|

Cylinder diameter |

63mm |

|

Cylinder stroke |

20mm |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com