- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

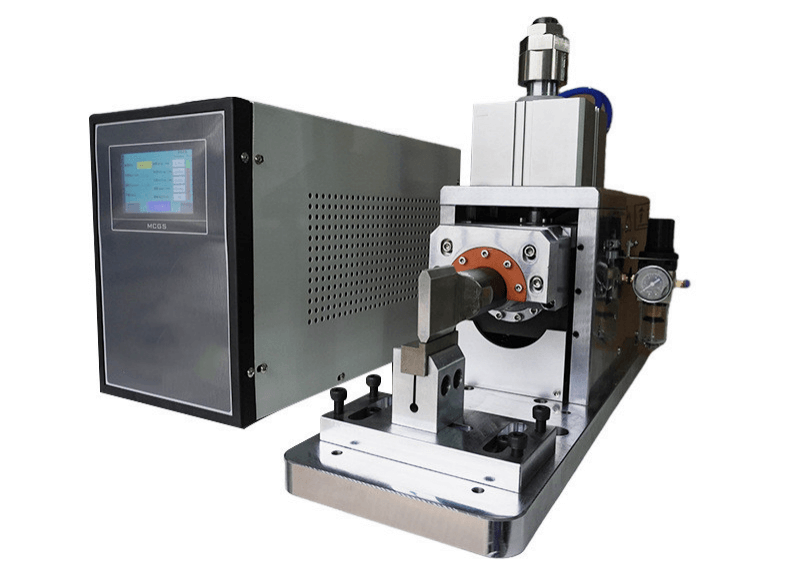

4000W 20KHz Ultrasonic Spot Welder Machine For Ni Al Metal Material Welding With Touch Screen Controller

Model Number:

TMAX-USW-4000WInput Power:

800WCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

3 Days

4000W 20KHz Ultrasonic Spot Welder Machine For Ni Al Metal Material Welding With Touch Screen Controller

Equipment Introduction

The machine consists mainly of an ultrasonic generator, transducer, mold, pneumatic components, and a frame. The working principle involves the transducer converting high-power ultrasonic frequency oscillation signals into corresponding mechanical energy, which is applied to the interface of the metal sheets needing to be welded. This causes the parts where the metal sheets join to instantly generate heat, resulting in the particles in the metal lattice to activate, making the molecules at the joining surfaces interpenetrate and fuse together.

Equipment Function

The product is used for welding aluminum foil to aluminum tabs and copper foil to nickel or nickel-coated copper tabs.

The welding of tabs is transverse, with a welding face lifespan of ≥100,000 times.

The welding head is standard, made of imported powder alloy material, with weld point heights of 050mm, with upper weld heads available in straight or cross patterns and the lower molds in mesh patterns. The weld face to weld joint height is adjustable from 050mm, and there are 2 welding faces available on the weld head.

The transducer can withstand a power of 4000W.

The ultrasonic generator is built-in with an adjustable frequency, constant voltage, constant current (constant amplitude), and stepless amplitude adjustment.

Performance Features

A. Uses advanced constant current, constant voltage circuit technology, with continuously adjustable ultrasonic amplitude.

B. Employs an intelligent ICS casing control system with a secondary ultrasonic function; self-check at startup, intelligent segmentation of amplitude, and automatic tracking.

C. The mechanical structure of the machine head uses German-style X rails for extremely high precision.

D. Protection systems include:

Voltage protection system (supply voltage range of 220V~250V) unaffected by automatic voltage stabilization;

Overload protection system;

Overcurrent protection;

Automatic compensation for unstable supply frequency;

Feedback signal for welding overload protection.

Technical parameters

|

Specification |

Details |

|

Power Supply Voltage |

50/60Hz-/AC220V |

|

Screen |

Touchscreen |

|

Frequency |

Automatic tracking |

|

Power |

4000W |

|

Frequency |

20kHz |

|

Welding Time |

Adjustable (0.01s-1s) |

|

Welding Method |

Single point |

|

Input Air Source |

Compressed air 7-8BAR (kilograms/square centimeter) |

|

Maximum Working Air Pressure |

6 kilograms/square centimeter |

|

Minimum Working Air Pressure |

0.3 kilograms/square centimeter |

|

Equipment Noise |

< 75dB when measured 1m from the outer wall of the equipment under normal operation |

|

Ambient Temperature |

20±5°C |

|

Ambient Humidity |

60%RH |

|

Environment Free From |

Corrosive gas, liquid, explosive gases |

|

Factory Floor Load Capacity |

≤800kg/square meter |

|

Equipment Dimensions |

|

|

Generator Size (L x W x H) |

550mm x 300mm x 550mm |

|

Machine Head Size (L x W x H) |

480mm x 200mm x 380mm |

|

Welding Head Material |

Imported high-speed steel |

|

Welding Surface Lifespan |

≥100,000 times |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com