- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

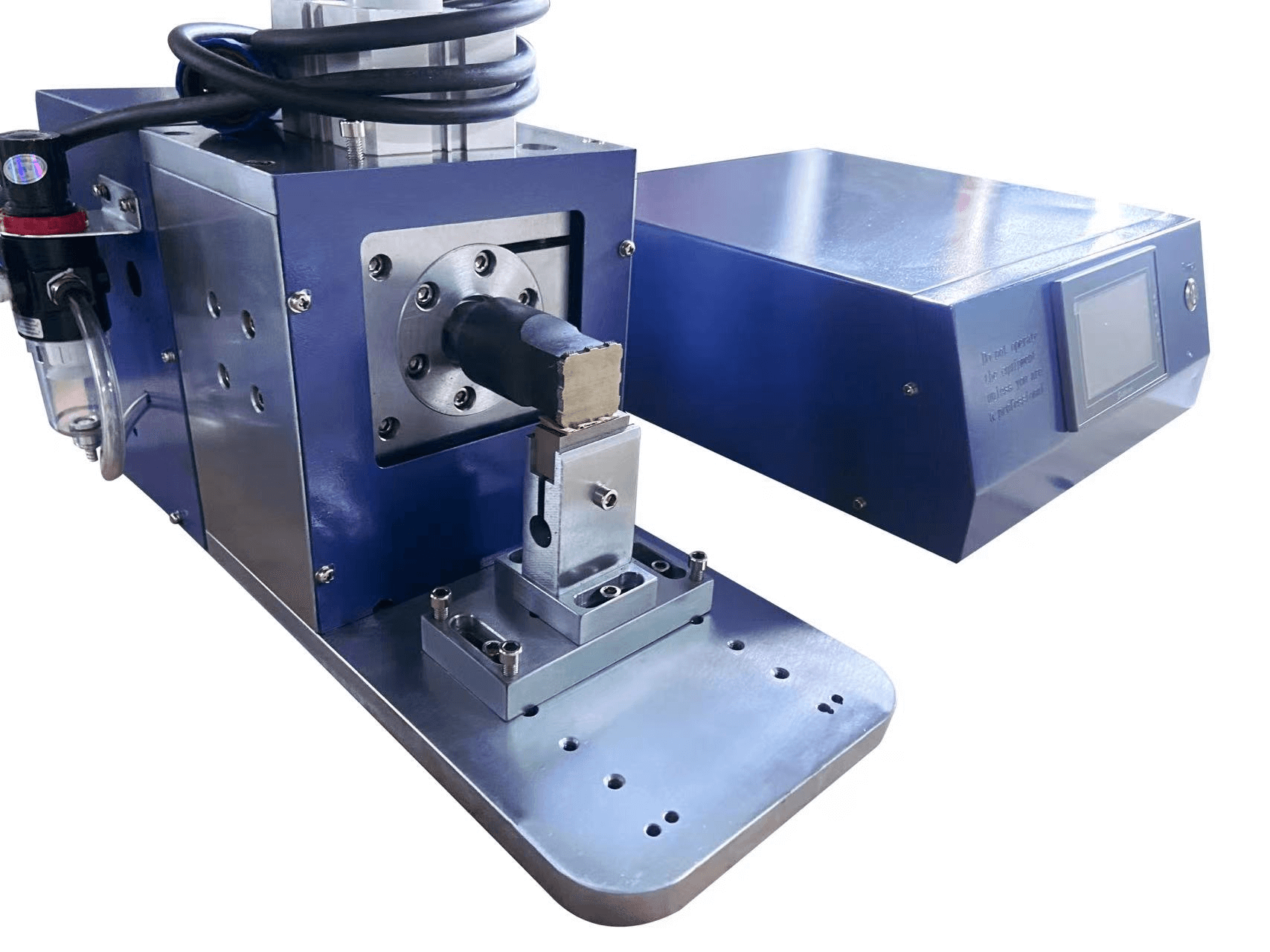

800W 40KHz Ultrasonic Spot Welder For Ni Al Material Welding With Parameter Save Function

Model Number:

TMAX-USW-800WInput Power:

800WCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

3 Days

800W 40KHz Ultrasonic Spot Welder For Ni Al Material Welding With Parameter Save Function

Using a high-performance anti-interference microprocessor to implement electronic control, the parameters of the welding control are managed by a microcomputer. An intelligent frequency control system eliminates the inconvenience of manual frequency tuning. Sound wave overload is automatically detected, and the system real-time tracks the optimal resonance point, keeping the temperature of the vibrating group at the lowest point. The machine automatically adjusts to frequency

Functional Features

◆ Fully digital ultrasonic system imported from Germany.

◆ The speed of the welding head's ascent and descent can be adjusted for accurate control.

◆ Able to precisely locate the vertical position of the welding structure.

◆ The ultrasonic generator can automatically compensate for output voltage fluctuations to ensure stable amplitude output from the weld head segment.

◆ Accurate energy control can ensure the stability of each weld and reduce the impact of external factors.

◆ The welding head equipment uses automatic frequency chasing, eliminating the need for manual tuning.

◆ Use of IGBT power modules plus self-excited oscillation circuit structures. Over 100 welding records can be queried.

◆ Cloud services can be customized. Intelligent protection for the machine and fault alarm prompts.

Transducer parameters:

Frequency difference between each transducer ≤ 39.5-40.5Hz

Impedance difference between each transducer ≤ 8Ω

Capacitance difference between each transducer ≤ 40PF

Insulation resistance between transducer and casing ≥ 30MΩ

Frequency control method Built-in adjustable frequency

Equipment design service life 8~10 years

Specification

|

Feature Category |

Feature Details |

|

Power Supply Voltage |

50/60Hz-/AC220V |

|

Screen |

Touch screen |

|

Digital System |

High stability |

|

Frequency |

Automatic tracking |

|

Power |

800W |

|

Parameter Save Function |

Yes |

|

Customizable Welding Parameter Recall |

Yes |

|

Welding Head Mode |

Single point pneumatic |

|

Welding Time |

Adjustable (0.01s-2s) |

|

Pre-pressure Time |

Adjustable (0.02s-10s) |

|

Frequency Calculation Display Search Range |

39.0000-41.0000HZ |

|

Adjustable Power |

500W, 800W |

|

Welding Mode |

Selectable |

|

Amplitude Adjustment |

Stepless amplitude adjustment |

|

Chassis Protection |

Intelligent protection and fault alarm prompts |

|

Automatic Frequency Tracking |

Range ±20HZ |

|

Automatic Temperature Tracking |

Internal power tube 60° automatic protection |

|

EMI/EMC |

Strong anti-interference ability |

|

Input Air Source |

Compressed air 7-8BAR (kilograms/square centimeter) |

|

Maximum Working Air Pressure |

6 kilograms/square centimeter |

|

Minimum Working Air Pressure |

0.3 kilograms/square centimeter |

|

Air Inlet Connector |

Quick connector 8mm |

|

Cylinder Diameter |

63mm |

|

Cylinder Stroke |

20mm |

|

Peripheral Dimensions |

About 900mm×600mm×750mm |

|

Total Weight |

About 60 kilograms |

|

Packaging Dimensions |

About 1000mm×600mm×800mm |

|

Chassis Size |

About 360mm×340mm×150mm |

|

Machine Head Size |

About 500mm×310mm×320mm |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com