- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

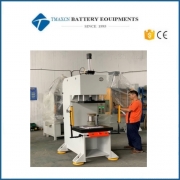

10T Single-Post Hydraulic Oil Servo Punching Press Equipment

Model Number:

TMAX-BSW07-10TCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

10T Single-Post Hydraulic Oil Servo Punching Press Equipment

Introduction

This series of hydraulic punch presses are widely applicable to press-fitting, assembly, punching, embossing, shaping and riveting of various materials. Bending, shearing, stretching, press-fitting and assembly of various small parts. It is a multi-purpose press.

The C-type hydraulic press has a simple structure and is lightweight, allowing it to be placed on a workbench or production line.

Features

1. Floor-standing hydraulic press has the characteristics of good rigidity, stability and high speed because it is a welding mechanism as a whole.

2. This series of hydraulic presses uses 2-20MPA liquid pressure as the power source, and external three-phaseAC380V 50HZ or three-phase AC220 60HZ AC power supply.

3. This series of equipment uses liquid as the medium to transfer energy. Lt adopts advanced sub-cylinder hydraulic circuit, the oil temperature is low, the idle speed is above 150MiM/sec, and the working speed is below 30 MM/sec

4. The equipment is on standby, and the noise does not exceed 75 decibels when moving up and down.

5. lt can be divided into manual and semi-automatic control modes. Manually, the press-fit upper mold can be stopped in any stroke range. lt can be equipped with an emergency rebound button or an infrared hand guard device.6. The press-fit stroke of this series of presses is generally controlled by a timer, pressure switch, position sensor, or the customer's own mold.

7. The height of the press-fit spindle can be adjusted by the timer or the position sensor within any stroke range.

8. Pressure, stroke, holding time, closing height can be adjusted by the customer for easy operation; with automatic counting function, can also be equipped with force measuring display, intelligent temperature controller, can be customized according to customer requirements.

9. The hydraulic mechanical output range of this series is available in various specifications of 15tf-100 tf(1tf=1000kgf=9.8KN).

Technical parameter

|

Model |

BSW07-10T |

BSW07-20T |

BSW07-30T |

BSW07-40T |

BSW07-50T |

BSW07-60T |

|

|

Nominal pressure(T) |

10 |

20 |

30 |

40 |

50 |

60 |

|

|

Maximum working pressure of liquid (MPa) |

21 |

21 |

21 |

21 |

21 |

21 |

|

|

Surface height(E) mm |

850 |

850 |

850 |

850 |

850 |

850 |

|

|

Maximum opening distance(H)mm |

400 |

400 |

500 |

550 |

550 |

600 |

|

|

Deep throat(s) mm |

200 |

200 |

225 |

225 |

250 |

250 |

|

|

Maximum stroke mm |

300 |

300 |

300 |

300 |

300 |

400 |

|

|

Workbench size |

Left and right (L) mm |

500 |

500 |

550 |

550 |

650 |

650 |

|

Before and after (W) mm |

400 |

400 |

450 |

450 |

500 |

500 |

|

|

Speed |

Rated load speed mm/s |

165 |

165 |

165 |

165 |

155 |

155 |

|

Working speed mm/s |

24 |

24 |

24 |

18 |

15 |

15 |

|

|

Return speed mm/s |

140 |

140 |

140 |

125 |

125 |

125 |

|

|

Main frame size mm |

700x950x2050 |

700x950x2060 |

760x950x2100 |

780x950x2150 |

800x950x2150 |

830x1000x2350 |

|

|

Power KW |

2.2 |

3.7 |

3.7 |

3.7 |

5.5 |

5.5 |

|

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com