- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

1200℃ Dual Zones Sliding PECVD Furnace

Model Number:

TMAX-1200-1200Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

1200℃ Dual Zones Sliding PECVD Furnace

TMAX-1200-1200 slip-type two-temperature area PECVD system is composed of TMAX-1200-1200 slip-type two-temperature vacuum tube furnace, quartz vacuum chamber, radio frequency power supply, GX gas supply system, pumping system and vacuum measuring system.

Main features:

1. The gas in quartz vacuum chamber is changed into ionic state by rf power supply.

2. PECVD is lower than normal CVD for chemical vapor deposition

3. The stress of the deposited films can be controlled by the frequency of rf power supply

4. PECVD has high deposition rate, good uniformity, consistency and stability than normal CVD.

5. Widely used in the growth of various films, such as SiOx, SiNx, SiOxNy and amorphous silicon (a-si: H), etc.

This slide TL1200-1200 type double temperature PECVD system technique is a rapid heating, cooling temperature PECVD system technique, is in the temperature range of double PECVD system installed on a pair of slide rail, technique available manual sliding system.

Heating and cooling rate of up to 100 ° C/min.

To get the fastest heating, heat the stove to the set temperature beforehand, then move the furnace to the sample position.

To get the fastest cooling, move the stove to the other end after the sample is heated.

Heating and cooling rate under vacuum or inert gas environment can reach 10 ° C/s, is a low cost rapid heating and cooling temperature range of double PECVD system technique.

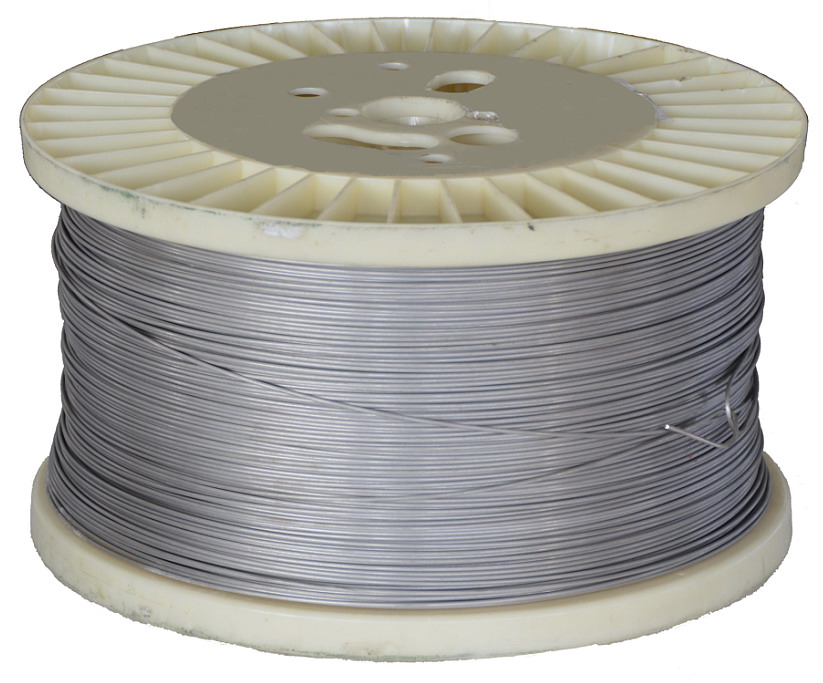

1. Kanthal A1 resistance wire of Sweden

Kanthal A1 Original wire Chinese resistance wire furnace VS Imported resistance wire furnace

(1), high surface temperature can reach 1420 ℃

(2) the surface is stainless steel (very bright, the customer should pay attention to it), it will not rust, and the use time will not fall off the slag.

(3) data of Kanthal resistance wire is downloaded

(4) Kanthal resistance wire website: www.kanthal.com

(5) the resistance is balanced and the temperature field is equally good

.jpg)

Most of the manufacturers use fe-cr-al Alloy doped by Mo resistance wire, which

Sometimes the resistance is uneven and part of the heat is small Kanthal A1 resistance is uniform and heat balanced, good Temperature field effect

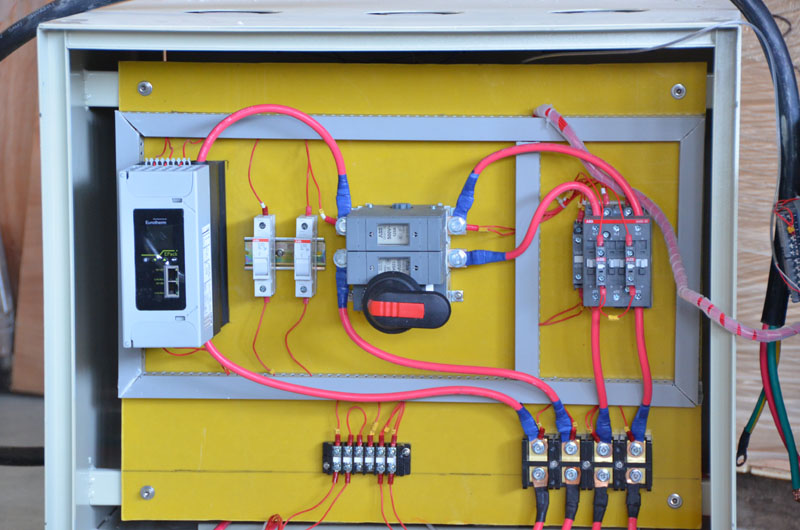

2. Installation of air switch and leakage protector:

When an electric current or leakage, an empty meeting automatically disconnects.

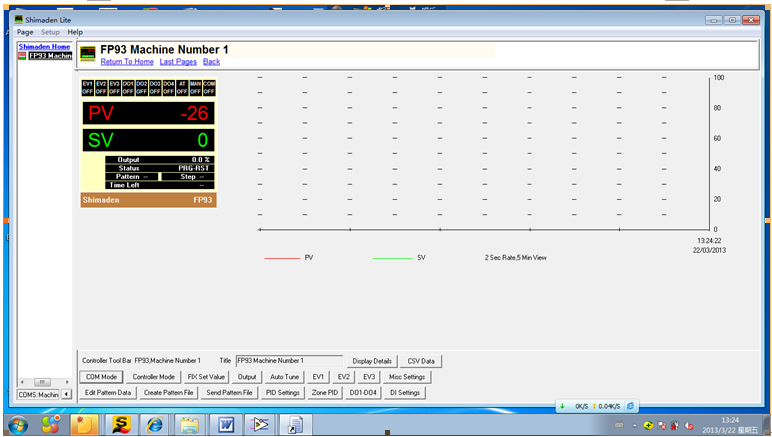

3. Can connect with computer

This furnace is equipped with communication interface and software, can be directly through the furnace computer control of each parameter, and can be observed from the computer PV on the stove and SV temperature value and instrument operation, the actual temperature of the furnace curve drawing computer real time, and can keep the temperature data of each time, can call up at any time

|

|

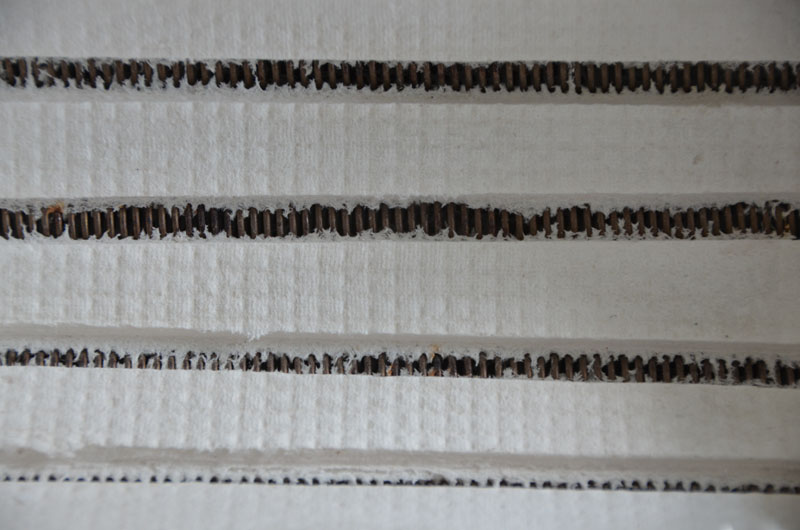

4. Chamber

(1) High quality high pure alumina polycrystalline fiber cured furnace with vacuum suction and filter molding.

(2). Adopt Japanese technology to form.

(3). The spacing and pitch of the resistance wire in the furnace are arranged according to the best thermal technology of Japan, and the temperature field is simulated by thermal software

(4). Using 4 weeks heating, the temperature is more balanced

5. optional UL certified electrical board (all through the UL certification of imported electrical appliances)

6. Trigger

Soft-start current limiting trigger Most manufacturers use non-limiting Xiamen Bode triggers

.jpg)

1 phase shift trigger (with soft start and current limiting function)

2. Current limiting function no matter how to adjust the heating time we electric furnace after the transformer secondary current is limited to 170A or less limited protection of the equipment. Non-limiting trigger if the heating rate is set incorrectly or too fast. Low current current is very large the device will trip or burn out.

3 soft-start function the current will slowly increase the current the impact of the heating element is small is conducive to the extension of the life of the heating element

4 the protection function If the current exceeds the limit current the trigger will automatically cut off the trigger function to cut off the current protection furnace.

7. UL certified transformer

1 the transformer cable is pure copper

2 the transformer sound small

3 the transformer temperature is low

8. A variety of options to choose a variety of flanges (diameter from 25 to 250mm)

|

model |

TMAX-1200-1200 - I |

TMAX-1200-1200-II |

TMAX-1200-1200-III |

TMAX-1200-1200-IV |

|

|

power |

3 kw |

3 kw |

4 kw |

4 kw |

|

|

Tube size |

120 (OD) X1800mm Dia |

60 (OD) X1800mm Dia |

80 (OD) X1800mm Dia |

100 (OD) X1800mm Dia |

|

|

Overall dimensions(LXDXH) |

1800 x480x680 |

1800 x410x610 |

1800 x410x610 |

1800 x460x660 |

|

|

The power supply voltage |

220 v |

||||

|

Slide rail material |

304 stainless steel |

||||

|

Sliding mode |

stainless steel rolling bearing |

||||

|

Number of phase |

Single phase |

||||

|

Heating element |

Import Swedish Canthal A1 resistance wire click into data download |

||||

|

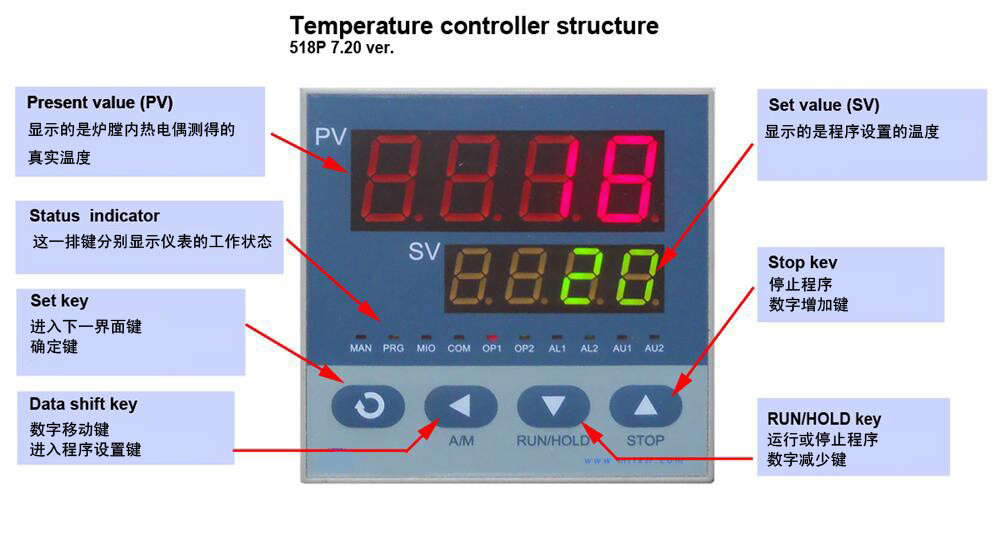

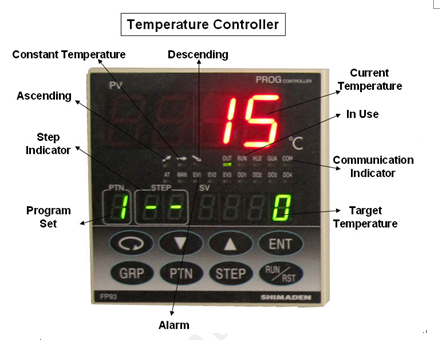

The control mode |

Using the yu electric program control thermometer (standard)

(to replace the imported instrument, we need to pay another fee.)

FP93 temperature control table(SHIMADEN) European instruments

Touchscreen instrument |

||||

|

The temperature control mode |

PID |

||||

|

Broken even protection and display |

Yes |

||||

|

Over temperature protection |

Yes |

||||

|

Over current protection |

Yes |

||||

|

Control precision |

+ / - 1 ℃ |

||||

|

The trigger |

Phase shift trigger |

||||

|

Electrical appliances |

Zhejiang chint |

||||

|

Silicon controlled rectifier |

106/16e west gate, Germany |

||||

|

The highest temperature |

Temperature Zone1: 1200 ℃ temperature zone 2:1200 ℃ |

||||

|

The rated temperature |

Temperature Zone1: 1100 ℃ temperature zone 2:1100 ℃ |

||||

|

Heating rate |

The 20 ℃ / Min or less (can modify according to the requirement) |

||||

|

Recommended heating rate |

10 ℃ / Min or less |

||||

|

Model of thermocouple |

Zones 1: temperature range of K type 2: K type |

||||

|

Heating length |

Zones 1: temperature range of 200 mm. 2:200 mm |

||||

|

Electrical certification |

CE |

||||

|

Surrounding surface temperature |

45 ℃ or less |

||||

|

Rf power supply |

(plasma generator) |

||||

|

Power output range |

0-500 w |

||||

|

Maximum reflected power |

200 w. |

||||

|

Working frequency |

Rf: 13.56 MHZ plus or minus 0.005% |

||||

|

Power stability |

+ / - 0.1% |

||||

|

Harmonic component |

- 50 or less DBC |

||||

|

Rf width |

0-600 - mm is adjustable |

||||

|

Matching mode |

automatic |

||||

|

Cooling mode |

Air cold |

||||

|

noise |

The < 50 db |

||||

|

The radio frequency interface |

50 Ω N - type |

||||

|

Input power |

208-240 - v 50/60 hz |

||||

|

Main parameters of GX gas supply system

|

mass flowmeter |

||||

|

Channles: |

1, 2, 3, 4, 5, 6, 7, 8 (optional ) |

||||

|

Joint type |

Double cassette stainless steel connector |

||||

|

System work pressure range |

0.1 ~ 0.5 MPa |

||||

|

Working temperature |

5-45 ℃ |

||||

|

Pressure vacuum watch |

0.1 ~ 0.15 MPa to 0.01 MPa/case |

||||

|

Static mixing chamber |

Dia50 X 400 mm |

||||

|

interface |

Dia6 1/4" |

||||

|

The power supply |

220 v |

||||

|

size |

600 x600x600 |

||||

|

Corrugated pipe |

KF25X1000mm |

||||

|

The vacuum degree can be reached with this system |

10-1 the pa |

||||

|

Vacuum baffle valve |

KF25 |

||||

|

VRD to 8 vacuum pump |

|||||

|

model |

VRD to 8 |

||||

|

Limiting partial pressure |

5 x10-2 Pa |

||||

|

Inlet exhaust interface |

KF25 |

||||

|

Motor speed |

1440 RPM |

||||

|

Extraction rate |

2.2 L/S |

||||

|

Motor power |

0.4 KW |

||||

|

Perfeer ACP1 Oil-free multi-stage roots pump (plan 2) |

|||||

|

Model |

ACP15 |

||||

|

Power supply |

AC100 ~ 240V 50/60hz |

||||

|

Power |

450 w |

||||

|

Exhaust interface |

KF25 |

||||

|

Weight |

25 kg |

||||

|

The maximum helium leakage rate is |

5 · 10-8 Pa m3 / s |

||||

|

Extreme vacuum degree |

0.02 Torr |

||||

|

The extraction rate is |

14 m3 / h |

||||

|

model |

ZDR - 1 |

||||

|

power |

25 w. |

||||

|

Vacuum degree measurement range |

0.1-10 5 Pa |

||||

|

Resistance silicon |

What ZJ had to 52 t |

||||

|

Sweden (INFICON) Pirani capacitance vacuum meter (optional) |

|||||

|

model |

PCG554 |

||||

|

Input voltage |

24V 1A DC (equipped with 220V transformer) |

||||

|

Vacuum gauge interface |

KF16 |

||||

|

Digital display |

Digital display (screen size 20x14mm), whose data display unit is torr |

||||

|

Product size |

46mm x 28mm x 126mm (L x W x H) |

||||

|

The weight of the |

5 LBS |

||||

|

Detection of gas |

Various gases can be detected including mixed gases, accurate and repeatable. |

||||

|

Whether the anti-corrosion |

Corrosion protection |

||||

|

The response time |

30 ms or less |

||||

|

Measuring range |

3.8 x10-5-1125 Torr. |

||||

|

Molecular pump unit (optional) |

|||||

|

Unit input voltage |

380 v / 220 v |

||||

|

Corrugated pipe |

KF40X1000 |

||||

|

Vacuum baffle valve |

KF40 |

||||

|

Case size |

600 x600x600 |

||||

|

Molecular pump model |

FJ620 |

||||

|

Input voltage |

380 v |

||||

|

Molecular pump inlet flange |

DN160 |

||||

|

Molecular pump pumping rate L/S (for air) |

600 |

||||

|

Molecular pump limit pressure (Pa) |

6 x 10-7 |

||||

|

Cooling system |

Water cooled |

||||

|

Cooling water pressure (MPa) |

0.1 to 0.2 |

||||

|

Cooling water temperature |

< 25 ℃ < p = "" > |

||||

|

The environment temperature |

0 ~ 40 ℃ |

||||

|

Suggested starting pressure |

< 100 pa < p = "" > |

||||

|

Engine vacuum pump RVP - 6 |

|||||

|

power |

0.75 KW |

||||

|

voltage |

380 v |

||||

|

speed |

1450 RPM |

||||

|

Inlet diameter |

KF25 / KF40 |

||||

|

Pump pumping rate (L/S) |

6 |

||||

|

Ultimate pressure |

4 x10-2 pa |

||||

|

German Pfeiffer vacuum pump |

|||||

|

voltage |

220 v |

||||

|

power |

110 w. |

||||

|

Extraction interface |

KF40 |

||||

|

The weight of the |

150 kg |

||||

|

Pump speed of the front pump |

0.9 m 3 / h |

||||

|

Extraction rate (N2) |

33 m/S |

||||

|

Compound vacuum gauge |

|||||

|

Compound vacuum gauge model |

ZDF |

||||

|

The power supply |

220 v 55 w |

||||

|

Control precision |

Plus or minus 1% |

||||

|

Vacuum gauge measurement range |

10-5-10 5 Pa |

||||

|

Parts |

Number |

|

TL1200-1200 Tube furnace |

1 set |

|

quartz tube |

1 |

|

SS Flange |

1 set |

|

Stainless steel hook |

1 |

|

Alumina furnace plug |

3 |

|

High temperature gloves |

1 pair |

|

alumina crucible |

1 |

|

K thermocouple |

1 |

|

485 transform interfaces and software(optional) |

1 set |

|

Instruction book |

1 |

|

Flange support |

1 |

|

Gas supply system |

1 |

|

VS-0.1air extracting system |

1 |

|

RF power |

1 |

|

Ferrule |

4个 |

|

Bellow |

1 |

|

Vacuum baffle valve |

1 |

|

Cyl connector(N stands for number of channels) |

N |

|

Valve connector |

2 |

|

PTFE pipe (N stands for number of channels) |

N*5 |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com