- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

1500℃ Dual Zone Split Tube Furnace

Model Number:

TMAX-1500DZFCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

1500℃ Dual Zone Split Tube Furnace

A.Overview

This tube furnace uses silicon carbide rods as heating elements, adopts a double-layer shell structure and an electronic temperature control instrument, which can perform multi-segment program temperature control, phase shift triggering, and SCR control. The furnace uses aluminum oxide polycrystalline fiber material. The two ends of the furnace tube can be sealed with stainless steel flanges. The stainless steel flanges are equipped with gas nozzles, valves and pressure gauges. The vacuum degree can reach 10-3 Pa when vacuuming. The furnace is horizontal. Easy to use and simple to operate. The furnace has the advantages of balanced temperature field, low surface temperature, fast rise and fall temperature, and energy saving. It is an ideal product for universities, scientific research institutes, and industrial and mining enterprises for high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, and vacuum annealing.

B.Specification

|

Type |

TL1500-1500-I |

TL1500-1500-II |

|

Power |

6KW |

6KW |

|

Tube size (OD, mm) |

Dia60 X1000 |

Dia80X1000 |

|

Supply voltage |

220V |

|

|

Phase |

Three phase |

|

|

Heating element |

The first temperature zone silicon carbide rod The second temperature zone: silicon carbide rod |

|

|

Temperature control

|

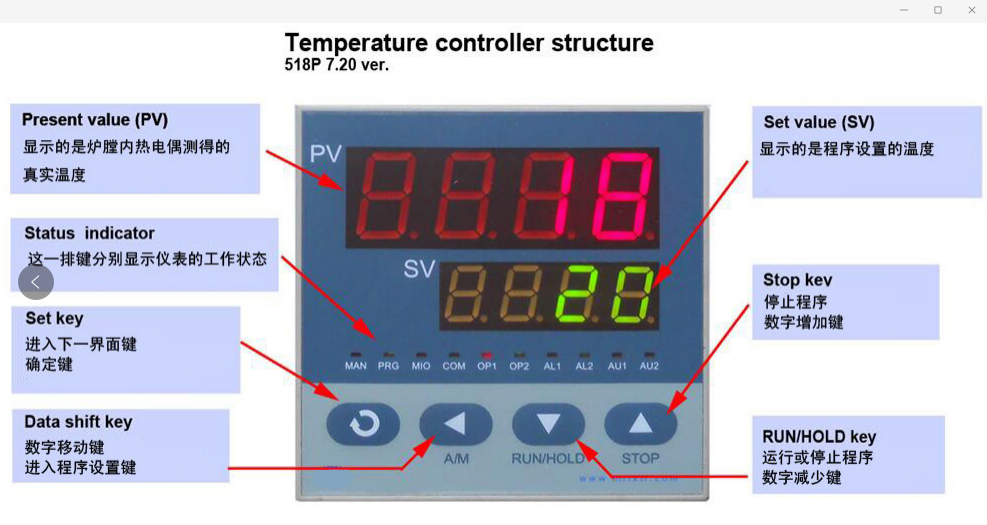

UAV program temperature control instrument (standard) 1.50 - stage program temperature control intelligent PID adjustment. 2.With over-temperature protection, the electric furnace heating circuit is automatically cut off when the temperature is over-temperature or broken, (when the electric furnace temperature exceeds 1520 degrees or the thermocouple is blown, the AC relay on the main circuit will be automatically disconnected, the main circuit is broken. On, the ON light on the panel is off, the OFF light is on, and the limited protection electric furnace). 3. With 485 communication interface (standard when purchasing software) 4. With power-off protection function, that is, when the power is turned on after the power is turned off, the program does not start from the starting temperature, but the furnace temperature rises from the time of power failure. 5. The meter has the function of temperature self-tuning

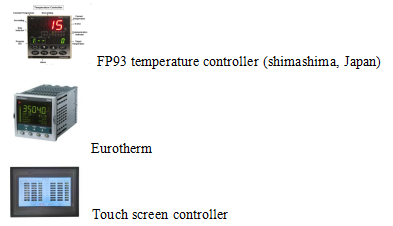

If you want to get an imported temperature controller, you may have the following choices for replacement with extra fees.

|

|

|

Chamber material

|

1. High-quality and high-purity alumina polycrystalline fiber curing furnace formed by vacuum suction filtration. 2. Japanese technology for forming. |

|

|

Control accuracy |

+/- 1 ℃ |

|

|

Trigger |

Phase-shifted trigger |

|

|

Electric appliance |

Zhejiang chint |

|

|

Silicon controlled |

106/16E SEMIKRON |

|

|

Maximum temperature |

1500 ℃ |

|

|

Rated temperature |

1400℃ |

|

|

Heating rate |

≤20 ℃/ Min (it can be modified as required) |

|

|

Recommended rate of temperature rise |

≤10 ℃/ Min |

|

|

Thermocouple Type |

S Type |

|

|

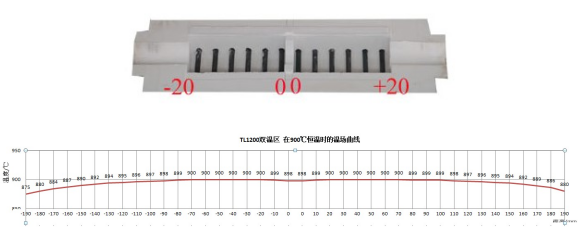

Heating length of the first temperature zone and the second temperature zone |

190+190mm |

|

|

Constant Heating length of the first temperature zone and the second temperature zone |

250+270mm |

|

|

Temperature field curve |

|

|

|

Temperature calibration (optional) |

Regular temperature calibration of the tube furnace maintains the accuracy and uniformity of the furnace temperature. You can purchase a simple calibration tool from the company to assist you with this work. The complete calibration kit includes a standard thermocouple S-type, temperature calibrator.

|

|

|

Vacuum system (optional) |

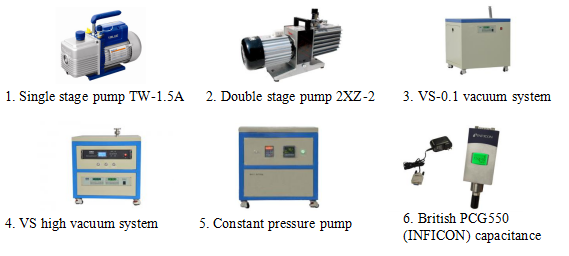

1) Generally, the gas in the furnace tube can be pumped out by roughly vacuumizing:TW-1.5A single-stage pump would be fine 2) The double-stage pump 2XZ-2 vacuum pump can pump the vacuum degree of tube furnace tube to about 10Pa. 3) The VS-0.1 vacuum system can pump the vacuum degree in the tube furnace to 0.1Pa (with resistance vacuum meter display). 4) VS high vacuum system (composed of molecular and mechanical pump) can pump the vacuum degree in the tube furnace to 10-3 Pa. 5) Constant pressure pump (the system can control the pressure in the pipe within - 100.0KPa ~ 100.0KPa). 6) British (INFICON) capacitance vacuum gauge (measuring range: 3.8x10-5 -1125 Torr, it can detect various gases, including mixed gases, with accurate measurement, good repeatability, and optional anti-corrosion type: PCG554)

|

|

|

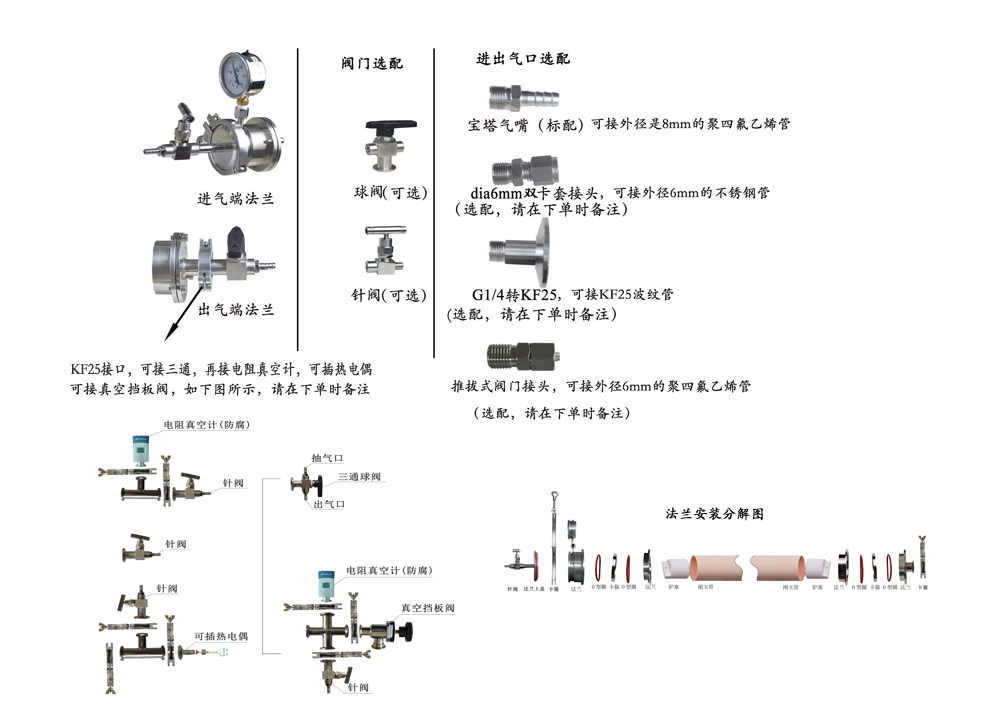

Valve and Flange |

|

|

|

Peripheral surface temperature |

≤45℃ |

|

|

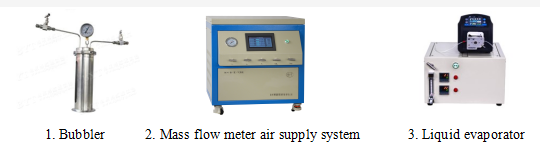

Gas supply system (optional) |

|

|

C.Precautions

1. The gas pressure in the furnace tube can not be higher than 0.02MPa

2. Since the internal pressure of the cylinder is high, when the gas is introduced into the furnace tube, a pressure reducing valve must be installed on the cylinder. To ensure safety, it is recommended to use a pressure lower than 0.02 MPa.

3. When the furnace tube used is a corundum tube, when the furnace temperature is higher than 1500 °C, the furnace tube should not be in a vacuum state, and the gas pressure in the furnace tube should be equivalent to the atmospheric pressure.

4. The gas flow into the furnace tube should be less than 200SCCM to avoid the impact of cold air flow on the hot furnace tube.

5. For the sample heating experiment, it is not recommended to close the suction valve and intake valve at the flange end of the furnace tube. If you need to close the air valve to heat the sample, you should always pay attention to the pressure gauge. If the air pressure is greater than 0.02 MPa, you must open the exhaust valve immediately to prevent accidents (such as furnace tube rupture, flange flying out, etc.)

6. Do not use graphite crucible in alumina tubes

7. MoSi2 heating element must not be used for a long time at low temperature (400 ° C - 700 ° C), otherwise it may damage the heating element

ru

ru

David@battery-equipments.com

David@battery-equipments.com