- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

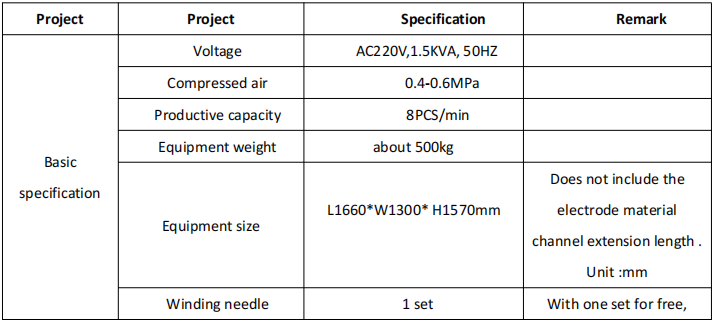

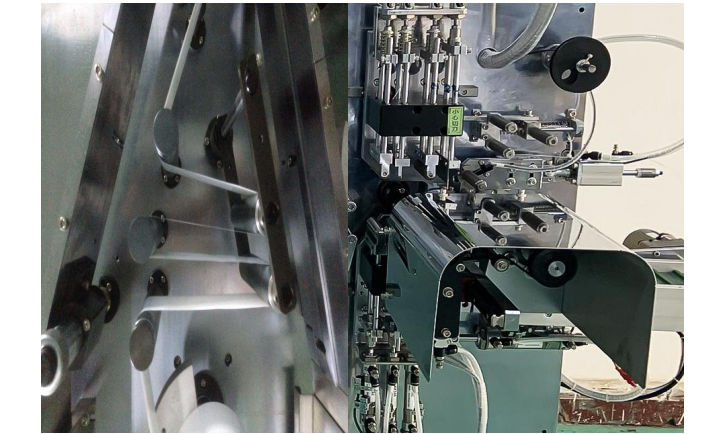

18650 Cylindrical Battery Assembly Semi-auto Electrode Winding Machine

Model Number:

Tmax-winding004Type:

Electrode Winding MachineDimension(L*W*H):

1000 mm L x 700 mm W x 900mm HNet Weight:

700KGCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

18650 Cylindrical Battery Assembly Semi-auto Electrode Winding Machine

Machine and function Description:

manually guide the cathode and anode electrodes into the winding part, and separated stacking with the separator, and the winding will be carried out according to the requirements of the process, automatically attaching the termination tape, and the cell will automatically feed.

Function and Features

2.9. Easy to operate,adjust and replace;

Working Process:

3.5.cut off the separator, and stick termination tape and unloading.

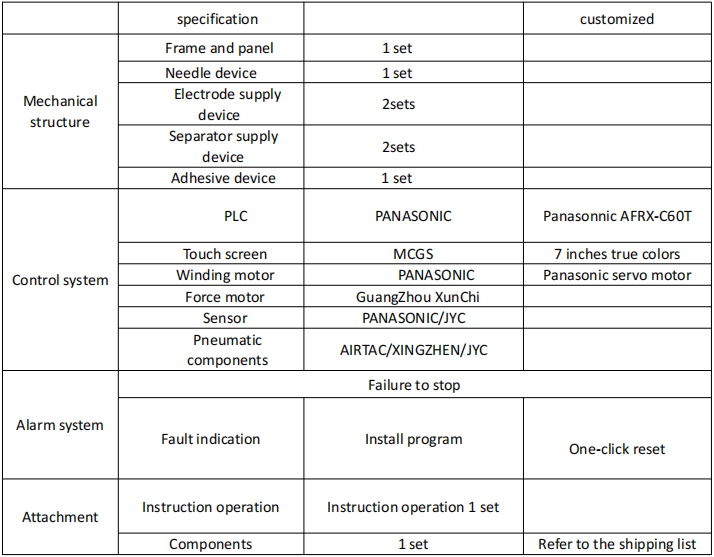

Main Device:

4.4. separator releasing device (2 sets) : the separator roll material is active to release and air pressureregulating control;

Technique Standard

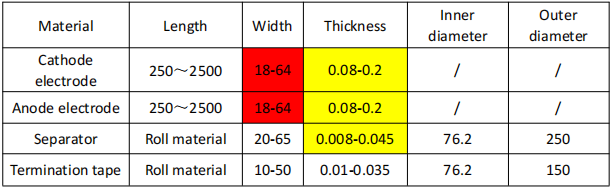

5.2 Material specifications (unit: mm)

5.6. Qualified rate: ≥98% (excluding equipment factors)

Technique Standard

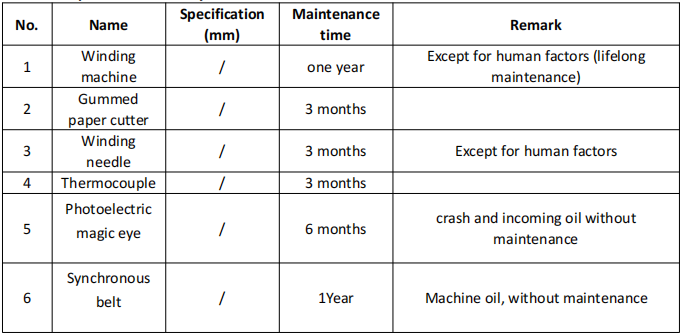

7. Breakable parts and warranty time

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com