- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

1L-12L Vertical Bench-Top Square Planetary Ball Mill With Standard Jar & Vacuum Jar

Model Number:

TMAX-BTBMType:

Planetary Ball MillCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

1L-12L Vertical Bench-Top Square Planetary Ball Mill With Standard Jar & Vacuum Jar

Through professional appearance design, the shell is made of high-precision die stamping, which is elegant and exquisite, high-end and stable. The planetary disk is cast, the structural components are processed by numerical control processing technology, the transmission gear is made of high-temperature wear-resistant nonmetal and metal combination precision gear, and the nitriding metal heat treatment process ensures the wear resistance of rotating shaft parts, prevents shaft breakage and ensures the high equipment height When running at high speed, it is stable and quiet, and the grinding tank fixing device can simultaneously lock and prevent loosening, which is convenient, safe and reliable.

Technical Parameters

|

Transmission mode |

Gear drive |

|||||||

|

Maximum sample loading |

2/3 of the capacity of the ball mill |

|||||||

|

Feed size |

Soil material≤10mm, other materials≤3mm |

|||||||

|

Discharge particle size |

Up to 0.1um minimum |

|||||||

|

Speed regulation mode |

Stepless speed regulation of frequency converter |

|||||||

|

Model |

Machine volume(L) |

Applicable standard jar volume |

Applicable jar quantity |

Applicable vacuum jar volume |

Power (kW) |

Runing time(min) |

||

|

DSP-1 |

1 |

50-250ml |

4 |

50-100 ml |

0.75 |

1-9999 |

||

|

DSP-2 |

2 |

50-500ml |

4 |

50-250ml |

0.75 |

1-9999 |

||

|

DSP-4 |

4 |

250-1000ml |

4 |

50-500ml |

0.75 |

1-9999 |

||

|

DSP-6 |

6 |

1-1.5L |

4 |

50-1000 ml |

0.75 |

1-9999 |

||

|

DSP-8 |

8 |

1-2L |

4 |

50-1500ml |

1.5 |

1-9999 |

||

|

DSP-10 |

10 |

1-2.5L |

4 |

50-2000 ml |

1.5 |

1-9999 |

||

|

DSP-12 |

12 |

1-3L |

4 |

1-2L |

1.5 |

1-9999 |

||

|

Model |

Alternate operation time |

Revolution speed(rpm) |

Rotation speed(rpm) |

Machine weight |

Machine dimensions(mm) |

Noise≤db |

||

|

DSP-1 |

1-999min |

35-370 |

70-740 |

90 |

780x470x570 |

60±5 |

||

|

DSP-2 |

1-999min |

35-370 |

70-740 |

93 |

780x470x570 |

60±5 |

||

|

DSP-4 |

1-999min |

35-370 |

70-740 |

93 |

780x470x570 |

60±5 |

||

|

DSP-6 |

1-999min |

35-370 |

70-740 |

95 |

780x470x570 |

60±5 |

||

|

DSP-8 |

1-999min |

35-320 |

70-640 |

148 |

920x600x640 |

63±5 |

||

|

DSP-10 |

1-999min |

35-320 |

70-640 |

150 |

920x600x640 |

63±5 |

||

|

DSP-12 |

1-999min |

35-320 |

70-640 |

152 |

920x600x640 |

63±5 |

||

Model selection guidance

Selection of size of planetary ball mill:

According to the number of materials to be ground, choose the size of the planetary mill.

Calculation formula for size selection of planetary ball mill: a = C /ρ* 3.

Note: A is the size of planetary mill (unit: l), C is the mass of primary grinding material (unit: kg), ρis the bulk density of grinding material (unit: kg /L).

For example, if 2kg of material is ground at one time and the bulk density of material is 1.5kg/L, the size of planetary mill in row a = 2/ 1.5*3 = 4L is selected.

Planetary ball mill style and special function configuration options:

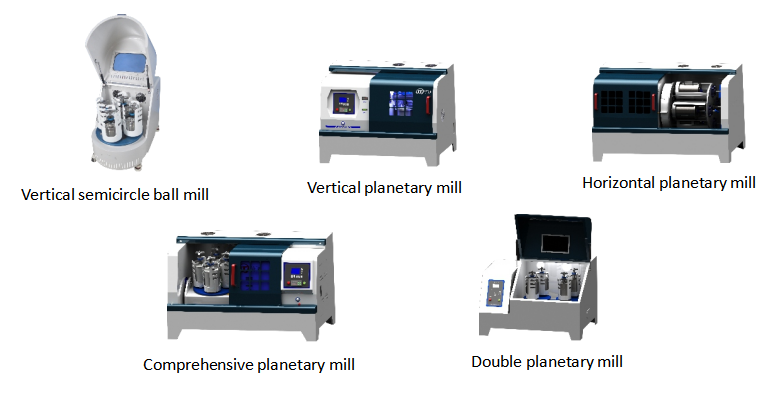

Planetary ball mill is divided into vertical, horizontal, comprehensive, double planet four styles, according to the material grinding requirements, choose the corresponding styles, each style of products can be equipped with air cooling or heating equipment according to the grinding material temperature requirements.

Reference table for selection of planetary ball mill style and special function configuration

|

Model selection of planetary ball mill |

Nature of abrasive material |

|

Vertical planetary mill |

Grinding of general materials, no special requirements |

|

Comprehensive planetary mill or horizontal planetary mill |

The material is easy to sink and bind |

|

Double planetary mill |

Ultra high speed and ultra-fine grinding are required |

|

With air cooling device or liquid nitrogen device |

The grinding process is hot and needs to be cooled |

|

Equipped with vacuum ball milling tank |

Easy to oxidize, requiring vacuum environment or atmosphere protection |

|

With heating device |

High temperature grinding required |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com