- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

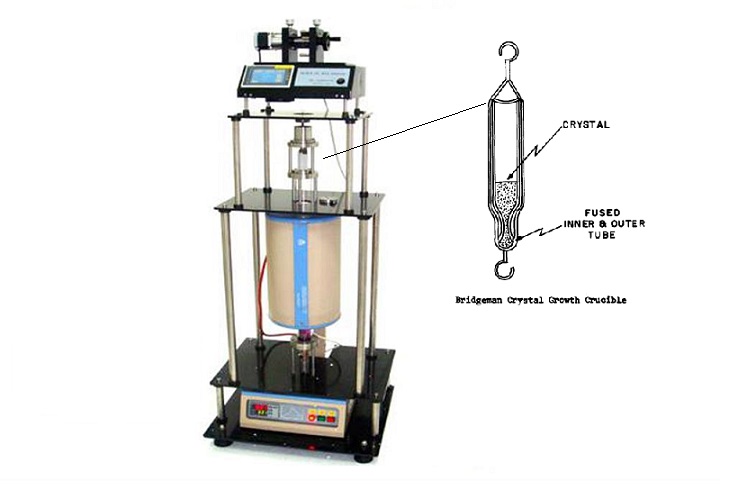

2" Vertical Tube Furnace Up to 1100C Programmable Dip Coater ( Bridgman ) with Atmosphere Controlled

Model Number:

PTL-HTDimension(L*W*H):

560mm(L) x 470mm(W) x 1435mm(H)Net Weight:

105kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

2" Vertical Tube Furnace Up to 1100C Programmable Dip Coater ( Bridgman ) with Atmosphere Controlled

PTL-HT is a CE Certified Programmable Dip Coater with 2" Tube Furnace and color touch screen controller. It is designed for R&D Lab to prepare various optical or epitaxial films from the liquid solution under a controlled temperature and atmosphere environment. Dipping rate, pulling rate, dwell time and life cycle can be set up via the touch screen control. The solution is located at the bottom of the sealed tube at room temperature, and the sample can go through a hot zone up to 800oC (to protect the stainless steel wire and sample clamp) under various gas atmosphere or vacuum for achieving high-quality epitaxial films.

SPECIFICATIONS:

|

Dip Coater |

1. Working Voltage: 110V AC ( or 220V )

|

|

|

Max. Power Consumption: 2KW Tube size: 2" (OD) x 24"(L) Heating Zone Length: 12" (300mm) Max. heating temperature: 1200°C Continuous working temperature: 1100°C 30 segment progtammable digital temperature controller Note: Max. working temperature for dip coating is limited by pulling wire

|

|

Pulling wire |

|

|

Stage Length |

1. Lower Stage (Pre-heat zone): 236mm 2. Center Stage (Constant temperature zone): 150mm 3. Upper Stage (Cooling zone): 234mm |

|

Product Dimensions |

560mm(L) x 470mm(W) x 1435mm(H) |

|

Compliance |

CE Certified

|

|

Warranty |

Two Years limited warranty with lifetime support

|

|

Application Notes |

1. In order to get better film coating, the substrate shall be treated by plasma cleaner

|

|

Accessories |

Purchase more 75ml solution beaker |

|

Net Weight |

105 kg (230 lbs) |

|

Shipping Weight |

137 kg (300 lbs) |

|

Shipping Dimensions |

48"(L) x 45"(W) x 70"(H) |

STANDARD PACKAGE:

|

Item |

Description |

Qty |

|

1 |

Dip Coater |

1 |

|

2 |

Furnace with 2" quartz tube and flanges |

1 |

|

3 |

LCD programmable controller |

1 |

|

4 |

800ºC Stainless Steel pulling wires |

3 |

|

5 |

Beakers |

2 |

|

6 |

High-Temperature Alloy Sample Holder (installed in the machine) |

1 |

|

7 |

Power cord |

1 |

|

8 |

Screwdriver |

1 |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com