- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

24T 500℃ Laboratory Double Plate Manual Hydraulic Hot Press Machine With Digital Display

Model Number:

TMAX-RYJ-600CGS/500℃Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

24T 500℃ Laboratory Double Plate Manual Hydraulic Hot Press Machine With Digital Display

The hot press is mainly used in some laboratories and units that need to perform high temperature and high pressure sample preparation or testing on powder samples, granular samples, plastic films and other solid samples. The particles or powders of the samples are heated and pressurized to make them chemically stable It has the advantages of improved performance, not easy to break, and good for cutting and preservation. It is an ideal supporting equipment for the engineering and technical personnel of various universities, colleges and research institutes to carry out spectroscopy detection and analysis. This machine can be used as a machine for multiple purposes, equipped with a suitable pressure die, and can also be used as an ordinary manual powder tableting machine. At the same time, the machine is also suitable for other working occasions that require corresponding pressure. It can be used as a press to test various objects. The degree of pressure resistance and so on.

The RYJ-600C electric heating tablet press is an intelligent, high-temperature hydraulic press developed by our company in accordance with market demand and on the basis of the original old hot press. This hot press has a very wide range of applications, which meets the needs of some customers for large tonnage pressure, especially the high temperature requirements for heating samples. This machine adopts our integrated structure patented technology. The main board, oil sump, and oil cylinder are on one main body. There is no sealing connection, which reduces the oil leakage point and reduces the oil leakage probability of the heat press. It is deeply loved by users at home and abroad.

Technical parameters

|

Model |

RYJ-600C |

RYJ-600CS |

RYJ-600CG |

RYJ-600CGS |

|

Model purchase |

Pointer pressure gauge |

Digital pressure gauge |

Pointer pressure gauge |

Digital pressure gauge |

|

Pressure range |

0-24T(0-34MPa) |

|||

|

Pressure conversion |

1T=1.41Mpa |

|||

|

Piston diameter |

Ф95mm chrome-plated cylinder |

|||

|

Max. piston stroke |

30mm |

|||

|

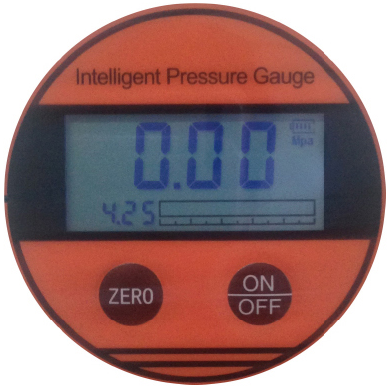

Pressure gauge type |

Pointer gauge, double scale display of pressure tonnage and pressure MPa |

|||

|

Digital pressure gauge |

Digital display 0.00-40.00MPa/0.01MPa (optional, only "S" type) |

|||

|

Pressure method |

Manual pressure |

|||

|

Thermostat type |

PID temperature controller |

|||

|

Number of thermostats |

2 sets |

|||

|

Temperature control range of thermostat |

RT -600.0℃/0.1℃ |

|||

|

Heating mold size |

100×100mm(2sets) |

|||

|

Mold heating temperature |

RT-300℃ |

RT-500℃ |

||

|

Mold cooling method |

Water cooling cycle to cool down quickly |

Water cooling cycle to cool down quickly |

||

|

Equipment insulation method |

Imported heat insulation board |

Imported heat insulation board + stainless steel water-cooled heat insulation board |

||

|

Power |

220V/600W |

220V/1000W |

||

|

Dimension |

1000×470×500mm |

|||

|

Host size |

245×175×500mm (without matching) |

|||

|

Weight |

About 60kg |

|||

|

Structure |

Split structure |

|||

|

Standard configuration |

1 hot press host, 2 thermostats (optional water cooler, 1 water cooler must be equipped above 300℃) |

|||

pressure conversion table

|

Model No. |

Pressure conversion table for RYJ-600C series double-plate heat press

|

|

|

Actual output pressure |

Pressure gauge system pressure |

Pressure gauge type |

|

1 T |

1.41 MPa |

|

|

2T |

2.82 MPa |

|

|

3 T |

4.23 MPa |

|

|

5 T |

7.06 MPa |

|

|

8 T |

11.3 MPa |

|

|

10 T |

14.1 MPa |

|

|

15 T |

21.2 MPa |

|

|

20 T |

28.3 MPa |

|

|

24 T |

34.0 MPa |

|

|

Pressure calculation formula |

The area of the oil cylinder/the area of the mold × the reading of the pressure gauge = the actual pressure of the mold (Mpa) |

|

|

Note |

The system pressure (ie pressure gauge reading) should not exceed 34MPa, otherwise it will affect the service life of the equipment |

|

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com