- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

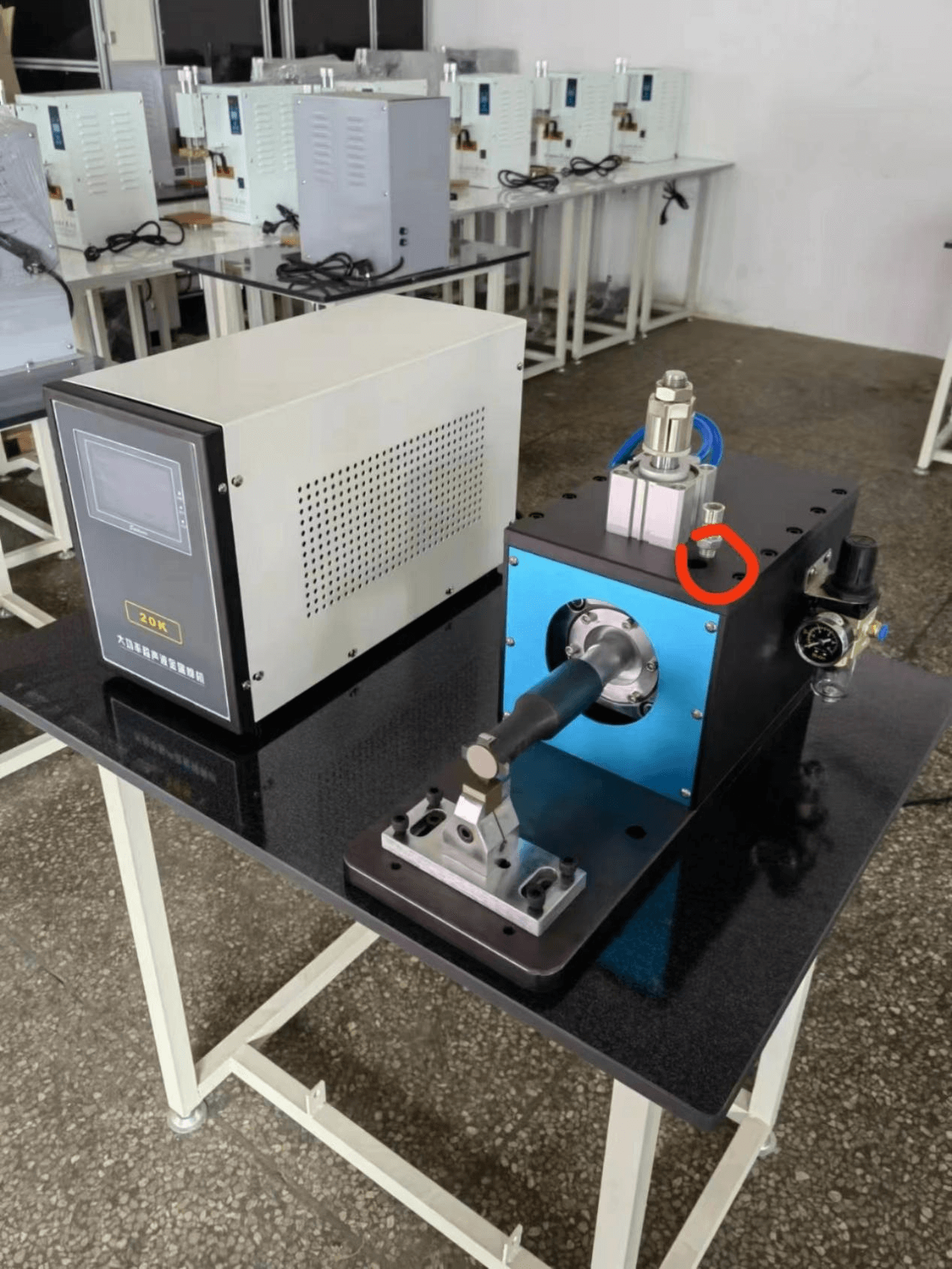

2600W 20KHz Battery Tab Ultrasonic Spot Welder For Multi-layer Metal Sheet Welding With Customized Welding Size

Model Number:

TMAX-USW-2600WInput Power:

2000WCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

2600W 20KHz Battery Tab Ultrasonic Spot Welder For Multi-layer Metal Sheet Welding With Customized Welding Size

Equipment function module

l This product is used for welding between aluminum foil and aluminum tabs, copper foil and copper nickel plated or nickel tabs

l The battery tabs welding method is horizontal, and the life of the welding surface is ≥ 100000 times;

l Welding head standard, welding head material is imported powder alloy, welding point height is 0~50mm, upper welding head straight grain or beige grain, lower mold mesh grain. The height from the welding face to the welding face is 0~50mm adjustable, and the welding head can be used with 4 welding faces.

l The transducer can withstand 2600W;

l The built-in frequency of the ultrasonic generator is adjustable, the switching power supply is constant voltage and constant current (constant amplitude), and the amplitude is stepless adjustable;

Performance characteristics

A. Adopt advanced constant current and constant voltage circuit technology, and the ultrasonic amplitude is continuously adjustable;

B. Intelligent ICS chassis control system with secondary ultrasonic function is adopted; Power-on self-test, intelligent segmentation and automatic tracking of vibration pair.

C. The mechanical structure of the machine head adopts German X guide rail structure, with high precision;

D. Protection system:

(1) Voltage protection system (power supply voltage range: 220V~250V); The output power and working frequency of the machine will not be affected during the automatic constant voltage period;

(2) Overload protection system;

(3) Overcurrent protection;

(4) Automatic compensation for unstable power supply frequency;

(5) Welding overload protection signal feedback.

General equipment configuration and standards

|

Equipment noise |

Measured at a distance of 1m from the outer wall of the equipment, the noise during normal operation of the equipment is less than 75dB. |

|

Equipment operation environment |

Ambient temperature: 20 ± 5 ℃; Ambient humidity: 60% RH; There is no corrosive gas, liquid or explosive gas on site. |

|

Plant bearing capacity |

≤ 800kg/m2 |

|

Overall dimension of equipment |

Generator size: L550mm x W300mm x H550mm; Welder size: L480mm x W200mm x H380mm; |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com