- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

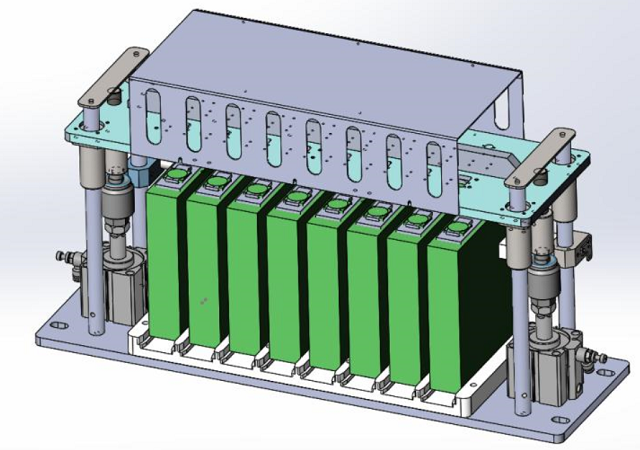

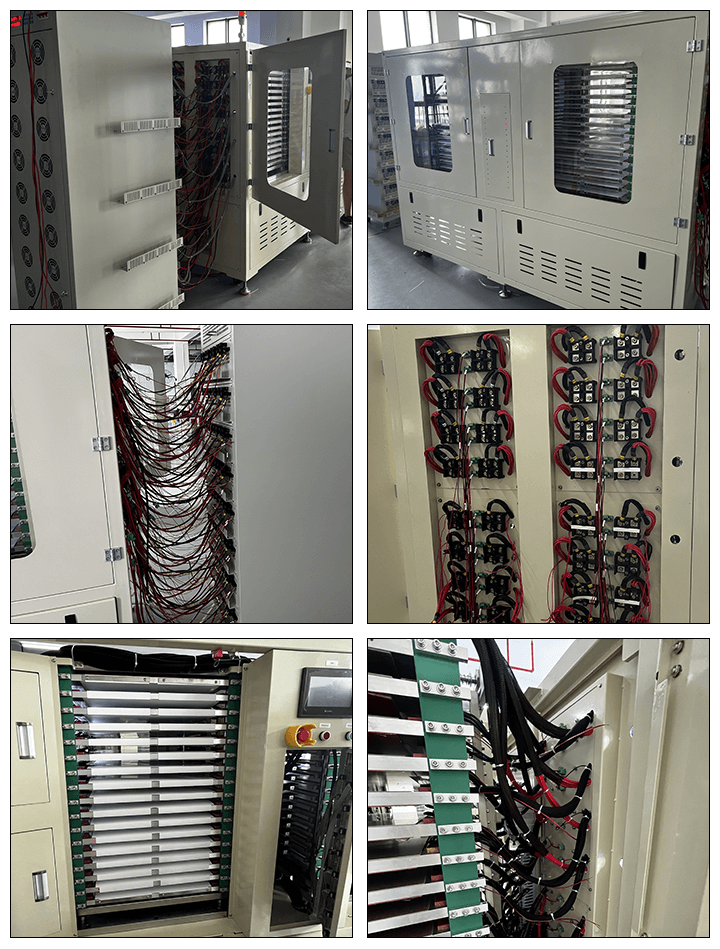

5V20A 64 Channel Prismatic Battery Negative Pressure Formation Machine

Model Number:

TMAX-YK-FYHC64CH-5V2Compliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

5V20A 64 Channel Prismatic Battery Negative Pressure Formation Machine

1. Device functions

1. Equipment function: the equipment is mainly used for lithium-ion prismatic batteries formation at high temperature(30-50℃)、negative pressure(-10--95),It can quickly activate the battery formation performance at high temperature, vacuum extract the air in the battery formation, shorten the formation time and shorten the battery production cycle.

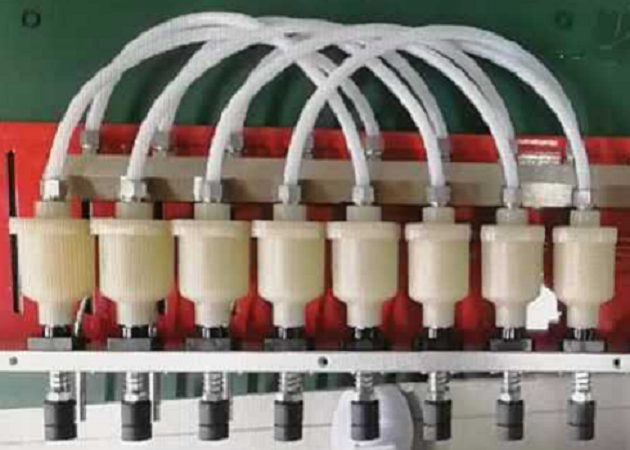

2. The equipment consists of a set of chemical power cabinet (5V20A, 64 points), 8 sets of needle bed fixture groups (8 points / set) and a set of negative pressure vacuum system (4 layers, 2 pipes with a diameter of 32mm in each layer, divided into 64 points, each single pipe with a diameter of 8mm, fluororubber anti-corrosion sucker); (the power supply and fixture are placed separately).

3. Workflow description:

The rail lift car sends the fixture group → pushes the fixture group into the needle bed → starts the needle bed → starts the negative pressure process and charges the formation → the formation is completed → automatically opens the needle bed fixture → the rail lift car manually withdraws the fixture group → the next round of fixture group charging formation

2、 Technical parameters

1. Suitable for prismatic battery:36130200(or 72173200);

2. Charging voltage setting range:DC 0~5V;

3. Discharge voltage setting range:DC 5~0.7V;

4. Charging and discharging current setting range:DC 0.05~20A;

5. Voltage accuracy:±(0.05%RD+0.05%FS);

6. Current accuracy:±(0.05%RD+0.05%FS);

7. Voltage resolution:1mV;

8. Voltage stability:≤0.1%;

9. Current resolution:1mA;

10. Current stability:≤0.1%;

11. Charging energy saving efficiency:Max: 80%;

12. Discharge feedback efficiency: up to 78%;

13. Power accuracy:±(0.05%RD+0.05%FS);

14. Current response time: when the current output is 30a, the hardware response time: ≤ 50ms;

15. Time setting range: any setting within 0 ~ 9999 minutes. The time units are h, min, s, and the resolution is 0.1S;

16. Time accuracy:≤±0.1%;

17. Recording mode: charging recording time, discharging recording time, static recording time, global recording time;

18. Recording frequency:100ms~65535s

19. Sampling frequency: single box around 10ms

20. Charging mode: constant current and voltage limit; Constant current and constant voltage; Constant power charging

21. Charging cut-off condition: voltage; electric current; Time; Capacity; temperature;

22. Discharge mode: constant current and constant power discharge;

23. Discharge cut-off condition: voltage; electric current; Time; Capacity; Temperature;

24. Single cycle work steps: ≤ 100 steps, with nested cycle function;

25. Continuous working time: the power of the equipment should meet the full load of all channels and 365 * 24-hour uninterrupted operation;

26. Software function:

1) The software supports various connections, such as manual pause connection, software shutdown connection, power interruption connection, equipment communication interruption connection, and abnormal stop connection;

2) It supports barcode scanning, which can scan one-dimensional code and two-dimensional code, including sequential scanning, channel skipping scanning, loading scanning and other scanning methods;

3) The local test detailed data storage allows you to view the current test data and historical data of each channel at any time. There are two ways to display the data corresponding to the curve, and it supports the export of Excel reports in single or batch form. In addition, you can set the automatic data import at the end of the test as needed.

4) Support capacity sorting and grade sorting of batteries;

5) Support the qualified judgment after the test, and judge the pass/ng result according to the specified cycle capacity, voltage, time and other information;

6) Support all kinds of work step protection and global abnormal voltage, current and temperature protection, and give abnormal alarm;;

7) Support channel parallel connection (optional according to equipment);

8) Support database server background storage or MES docking;

9) Software offline protection;

10) The software provides free upgrades.

27. Protection function

1) Data abnormal recovery

2) Software over voltage, under voltage, over current, under current and over capacity protection;

3) The range of voltage and current protection values can be set, and prompt and record can be made after protection;

4) Set the high-level alarm lamp to indicate the status;

5) Set the emergency stop button, and the fixture will open automatically during the emergency stop;

6) Smoke alarm is installed. When smoke alarm occurs, the machine stops running and alarms;

7) After the equipment alarm stops, you can continue the unfinished process from the interrupted position without starting the process from the beginning;

8) If the communication between the lower computer and the upper computer is interrupted and the communication returns to normal, the work can continue according to the original process;

28. In case of time communication interruption or PC failure, the equipment will automatically enter the waiting state, and continue the current process after the communication is quickly reset.

29. Technical parameters of vacuum part:

1) Reach vacuum: -1kPa~-95kPa;

2) Vacuum setting resolution:±0.01Pa。

3、Configuration of main components

1. Schematic diagram of fixture structure

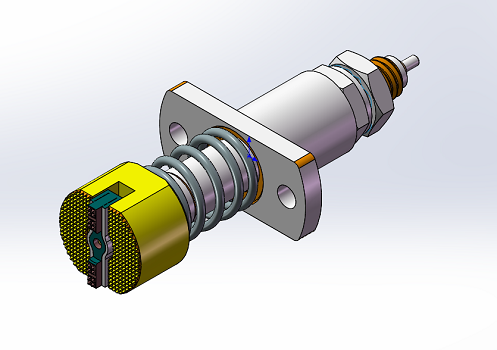

2. Structure diagram of high current probe

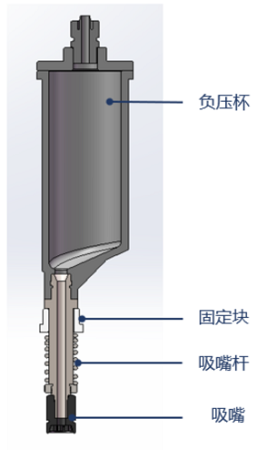

3. Structural diagram of negative pressure suction cup

4.Negative pressure cup (the overall structure is made of special treatment materials, which are corrosion-resistant and high temperature resistant, and the negative pressure pipeline is made of flexible PTFE corrosion-resistant materials)

4、Brand of components and spare parts:

1. 1. Configuration of main devices

|

SN |

Name |

Brand |

|

1 |

Digital vacuum pressure gauge |

SMC |

|

2 |

Pneumatic components |

AirTAC/SMC |

|

3 |

Thermostat |

Omron / Panasonic |

|

4 |

Test probe |

Customized (copper plated) |

|

5 |

sucker |

customized |

|

6 |

PLC |

Mitsubishi / Xinjie |

2. Attached accessories

|

SN |

Name |

Specification |

Qty |

Service cycle |

|

1 |

Testing probes |

Customized |

2pcs |

Above 10000times |

5、Installation environment requirements

1. Configure power supply:AC380V,50Hz, Pressure fluctuation range:+10%~-10%;

2. Total Powr: 13KW;

3. Compressed air:0.6~0.8Mpa;Barometric fluctuation:±1%

(Clean air after water removal, oil-free, filtration and pressure stabilization);

4. Vacuum source:-0.25~0.95Kpa;

5. Dry nitrogen source:0.1~0.3Mpa;

6. Equipment specifications:

1) weight:about 400kg;

2) Size:L 1800mm x W 800mm x H 1950mm;

3) Appearance color: light gray or customer specified.

7. Environmental requirements:

1) Environmental requirements: 0~45℃;

2) Relative humidity:30%~75%RCH,Ensure that the air on site is dry and unblocked without acid-base corrosion;

3) Ground wire: protective grounding

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com