- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

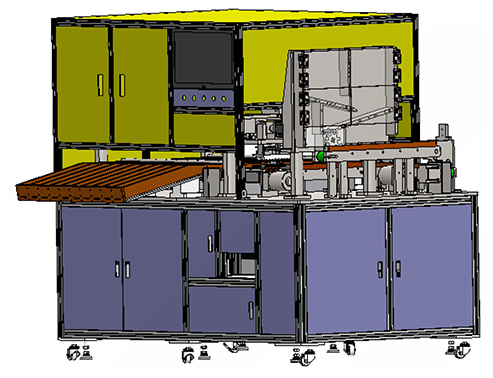

5 Channel Prismatic Battery Sorting Machine

Model Number:

TMAX-ZW-FX5SCompliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

5 Channel Prismatic Battery Sorting Machine

Application

This equipment is mainly used for sorting and testing the voltage and internal resistance of square shell battery.

Equipment Composition

The equipment provided by Party B consists of electrical, mechanical and chassis parts. The main components are divided into feeding structure, testing structure, sorting structure, etc.

Comprehensive performance of equipment.

Basic Parameters

|

Equipment efficiency |

20 ~ 25ppm |

|

Equipment moving rate |

≥ 95% |

|

Instrument internal resistance detection accuracy |

± 0.5% rdg display resolution 0.01 milliohm |

|

Instrument voltage detection accuracy |

± 0.05% rdg display resolution: 0.1 mV; |

|

Internal resistance detection repetition error |

< 1 milliohm (AC internal resistance detection method) |

|

Voltage detection repetition error |

< 1 mV |

|

Input power supply |

AC220V / 50Hz , 1KW |

|

Size |

L * W * H = 1400 * 700 * 1600mm |

Main Components

1. Tester: HK3561 high precision built-in tester

2. Linear guide rail: HIWIN / TBI

3. PLC: embedded motion control system

4. Motor: high performance stepping motor, Beifu / research control

5. Cylinder: Yadeke / Xingchen

6. Solenoid valve: Yadeke / Xingchen

7. Sensor: Omron / Bochuang

General Configuration

1. Appearance color of equipment: standard color warm gray 1C.

2. Equipment noise: ≤ 65dB.

3. The equipment complies with the national safety standards for electromechanical equipment, and there is no obvious or potential design safety hazard.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com