- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

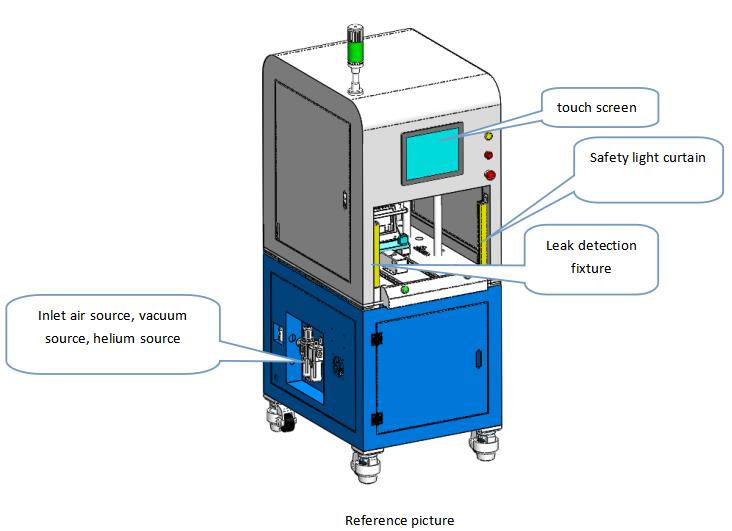

Prismatic Battery Air Tightness Tester For Helium Detection

Model Number:

TMAX-YK-QMCS-230Compliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Prismatic Battery Air Tightness Tester For Helium Detection

1、Instruction

It is used to detect the effect of laser welding and judge whether the battery after welding has holes

Workflow description:

Manually put in the battery, clamp and position the fixture, press down the measuring mechanism, vacuum and maintain the pressure, detect the discharge of helium, judge OK and ng, reset the measuring mechanism, loosen the fixture, and take out the battery.

2、Basic parameters

1. Configure power supply:

AC220V,50Hz, Voltage fluctuation range:+8%~-8%;Total power: 0.5KW。

2. compressed air:

0.4MPa~0.6MPa,Barometric fluctuation ±1% (Clean air after water removal, oil-free, filtration and pressure stabilization)

3. Vacuum source:≤-0.095 kg/cm2

4. Equipment specifications:

4.1Total weight:about 0.5T

4.2 Size:L(1m)*W(0.8m)*H(1.6m)

4.3 Appearance color: except for the stainless steel part, the box color is computer gray.

5. Environmental requirements:

5.1 ambient temperature: 25 ± 5 ℃.

5.2 relative humidity: 30% ~ 75% RCH, which should ensure that the air on site is dry and unblocked without acid-base corrosion.

5.3 ground wire: protective grounding.

3、Specification

1.work efficiency:1ppm(34155);

2.Equipment failure rate:≤0.5%

3.Test pressure:10-100kpa

4.measurement accuracy:±0.2%

5.resolving power:1pa

6.Insulation class :A grade

7.Enclosure protection grade: Grade 6

4、Process performance

1.Applicable battery size: height 120-225mm,W 100-180mm,T 20-60mm

2. Applicable battery model of fixture: see the attached drawing

3. There shall be no air leakage during the inspection of the tested mold and battery liquid injection hole

4. The equipment is equipped with a safety light curtain alarm

5. NG products have alarm prompt and counting functions

6. When the probe is lowered, it needs to avoid the pole. The probe uses a guide rod with a diameter of 8 to install a custom seal ring to avoid the battery pole.

7. Adopt pneumatic sealing fixture, and push the electric core by the air cylinder to make the liquid injection hole of the electric core closely fit the interface of the leak detector to form a closed circuit;

8. Support positive pressure leak detection and negative pressure leak detection; Automatically track the background and provide fast and reliable measurement results

9. The optimized mass spectrometry system and intelligent algorithm ensure rapid response in all ranges, and the highly reliable vacuum system and mass spectrometry system ensure rapid helium removal

10. It supports nitrogen air breaking, is not disturbed by environmental ammonia, and quickly reduces the background. The excellent performance of the machine supports 7 * 24 hours of long-time online testing

11. The excellent performance of the machine supports high rate tests every few seconds

12. Equipped with leak detection port fine filter to filter fine impurities, so as to ensure that the machine is not affected and damaged by impurities; Double iridium wire ion source, effective system design, anti atmospheric impact

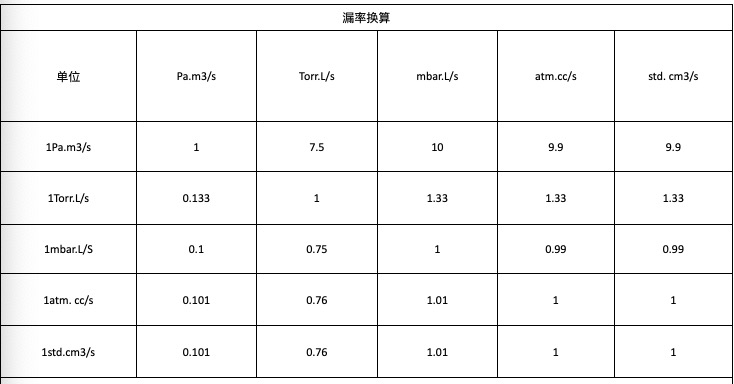

(leakage rate conversion)

5、Configuration of main components

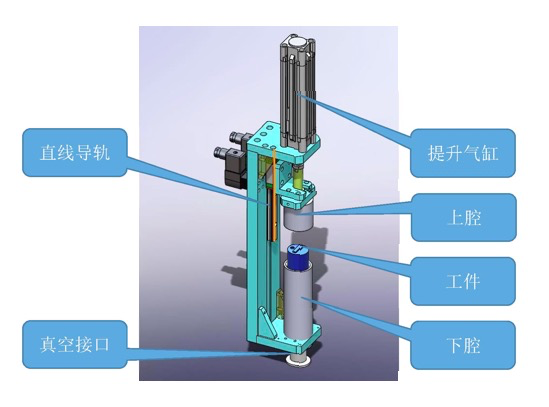

1、Air tightness and insulation resistance detection mechanism

直线导轨:linear guide rail

真空接口:Vacuum interface

提升气缸:Lift cylinder

上腔:Upper chamber

工件:Workpiece

下腔:Inferior chamber

2、Core feeding mechanism

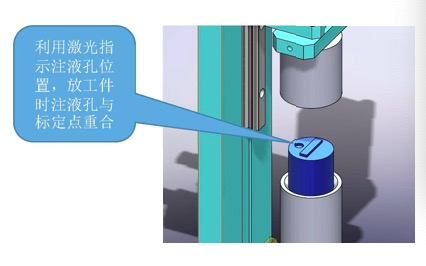

利用激光指示注液孔位置,放工件时注液孔与标定点重合

Use the laser to indicate the position of the liquid injection hole, and the liquid injection hole coincides with the calibration point when placing the workpiece

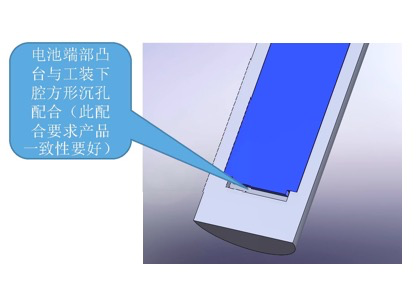

3、Cell positioning mechanism

The boss at the end of the battery is matched with the square counterbore in the lower cavity of the tooling (this matching requires good consistency)

电池端部凸台与工装下腔方形沉孔配合(此配合要求一致性要好)

6、Main Spare Part

1.Configuration of main part

|

SN |

Name |

Brand |

|

1 |

touch screen |

Weilun / Xinjie |

|

2 |

PLC |

Panasonic / MITSUBISHI |

|

3 |

Cylinder |

AirTAC |

|

4 |

Vacuum digital pressure gauge |

SMC |

|

5 |

guide |

THK |

|

6 |

Air switch, contactor |

chint |

2.Attached accessories

|

SN |

Name |

Specification |

Qty |

Recommended replacement cycle |

|

1 |

Sealing rings |

Cycle Ø4 |

10PCS |

1month |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com