- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

900C Small Tonnage Manual Hot Press

Model Number:

TMAX-PC-900LNet Weight:

58kgWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

900C Small Tonnage Manual Hot Press

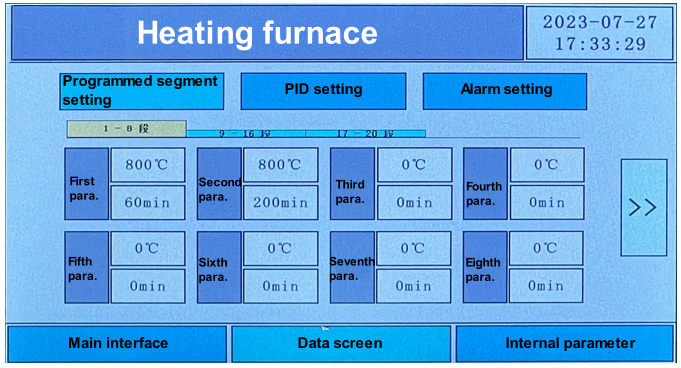

Setting interface

Step 1: Select the data screen and enter the Settings screen

Step 2: Select "Programmed Segment Settings"

Step 3: There are 20 temperature control procedures in the program, select the first paragraph

Step 4: According to the requirements of the experiment, set the temperature and heating speed of the first stage

Step 5: If you need multiple heating procedures, you can set up 20 procedures

Step 6: After setting, press the main screen to return to the operation screen

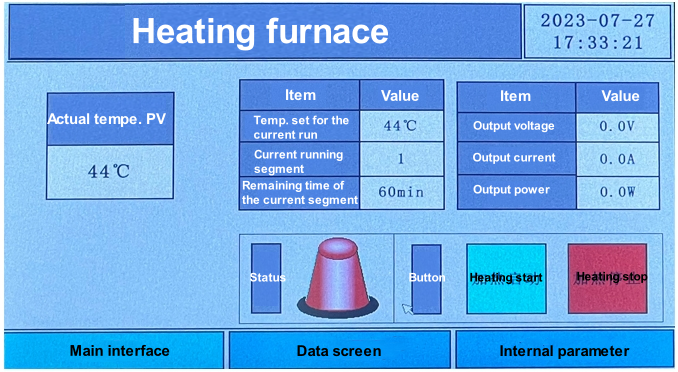

Operating interface

Step 7: On the main screen, press "Heating start"

Step 8: The device is programmed to heat up.

Step 9: Automatically stop the device after the end of heating. If the setting is wrong, for example, the set temperature is not reached within the specified time, the device will automatically terminate.

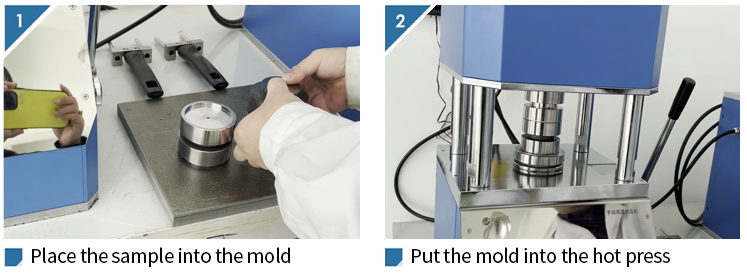

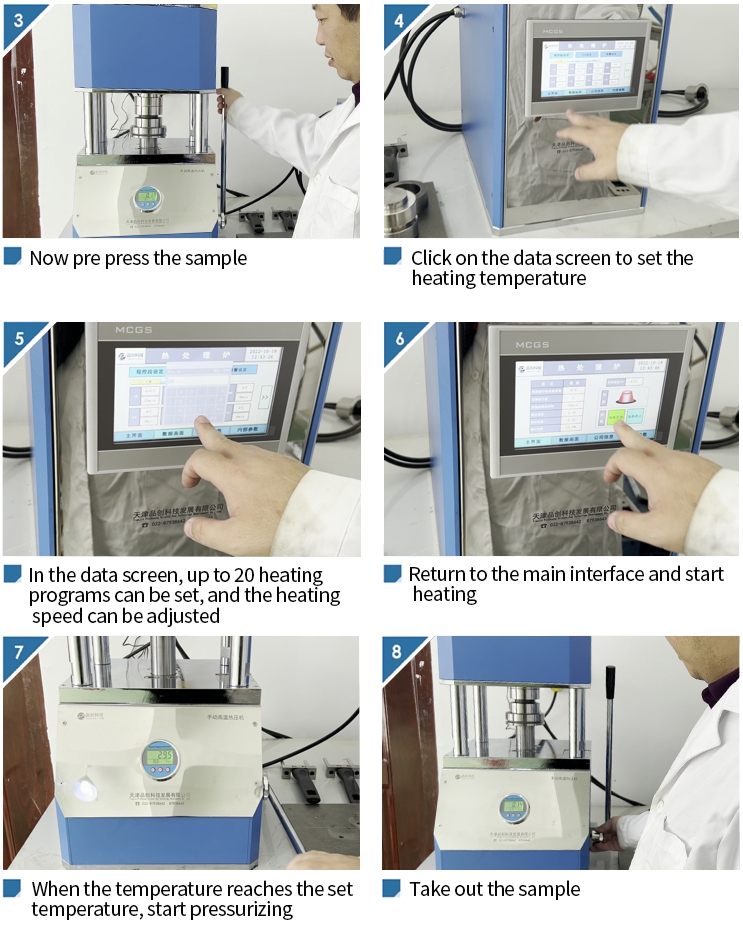

Operation procedure

Technical parameter

|

Instrument type |

PC-900L |

|

Pressure range |

0-5.0 tons |

|

Pressurization process |

Manual pressure |

|

Holding time |

1 s to ∞ s |

|

Cylinder stroke |

80mm |

|

Heating temperature |

Up to 1000℃ |

|

Mold material |

Nickel base alloy (high temperature resistant material) |

|

Sample size |

Ф 10 to 30 mm |

|

Mold contour |

Ф 50 x90mm |

|

Furnace aperture |

Ф 60 mm |

|

Overall size |

400x380x780(LxWxH) |

|

Power source |

220V 50Hz |

|

Hot press size diagram |

|

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com