- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

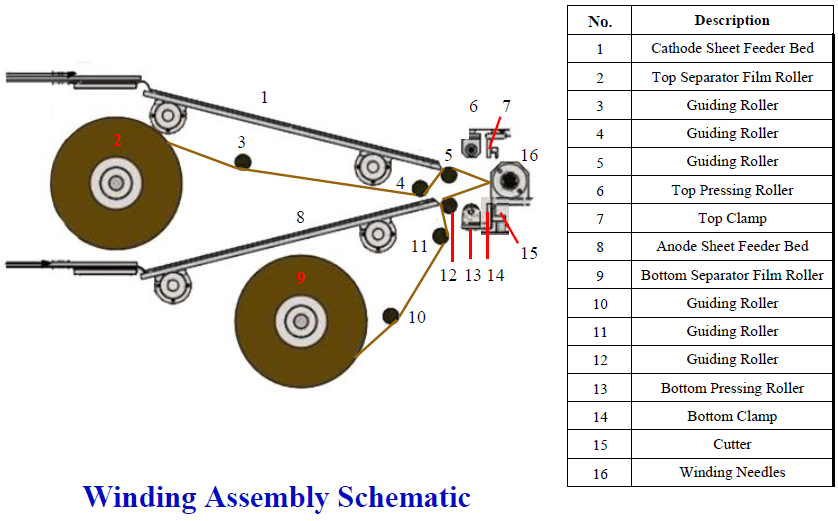

Automatic Winder Machine for Multi-Cylindrical Battery Core Winding

Model Number:

TMAX-YSSAType:

Electrode Winding MachineNet Weight:

550kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Automatic Winder Machine for Multi-Cylindrical Battery Core Winding

TMAX-YSSA is a fully automatic winding machine for assembling muti-cylindrical cell cores (also known as “jelly roll”) at 10 PPM ( 10 pack per minute). The batch of cathode and anode strips ( pre-welded tab), roll of separator and roll of tape are pre-installed in the machine, then you can touch button to wind the core of cylindrical cell automatically at 10 PPM speed up to 200 cell per batch

SPECIFICATIONS

|

Features |

Color touchscreen control Pre-loading one batch electrodes, one roll of separator, and one roll of tape, then touch button to go Automatic finish cut and tape upon the completion of the configured number of rotations 10 pcs per minute speed for each batch up to 200 cells. Optional for 18650, 21700 or 26650 cell |

|

Input Power |

Single phase 208 - 240 VAC, 50 / 60 Hz 2 000 W power |

|

Compressed Air (Optional part) |

Compressed air of 0.7 MPa is needed for the operation of this machine Please note the air compressor is not included. |

|

Cathode / Anode Feeding |

Pre-loading one batch of electrodes ( 100 trip max.), one roll of separator, and one roll of tape, Vaccum holder will absorb the electrode strip in one by one to feed into assembling line Width range: 25 – 70 mm (adjustable on feeder bed) Thickness range: 100 – 300 μm |

|

Separator Feeding |

Loading material: separator film rolls, such as polyethylene (PE) or polypropylene (PP) Length range: separator roll with a diameter < 250 mm Width range: 25 – 70 mm Thickness range: < 100 μm Tension range: 0 – 4 N for both top and bottom separator films |

|

Winding |

Winding needle size: 3.5 mm OD Electrode winding size: 14 – 32 mm OD, 25 – 70 mm in length To wind an electrode core with a certain OD, a spreadsheet for calculating needed number of turns and electrode sheet length Winding speed: 0 – 400 rpm adjustable Winding precision: < 0.5 mm edge roughness |

|

Tape Loading |

One roll of tape pre-load on the machine for strapping finished electrode core with the tapes Roll diameter: 150 mm Max. When winding finished, the tape will be applied to the winded core and cut. |

|

Size |

1600 mm L x 1300 mm W x 600 mm H |

|

Net Weight |

800 kg |

|

Warranty |

One-year limited warranty on lifetime support Rusting or damage due to improper storage conditions or maintenance is not covered by warranty |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com