- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Battery Cycler Electrochemical Analyzer ECT Series

Model Number:

TMAX-ECTCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Battery Cycler Electrochemical Analyzer ECT Series

Characteristic

1. Provides accurate benchmark data for lifespan prediction, inventory efficiency, self-discharge, and micro-reaction testing, with voltage and current precision of 0.01%.

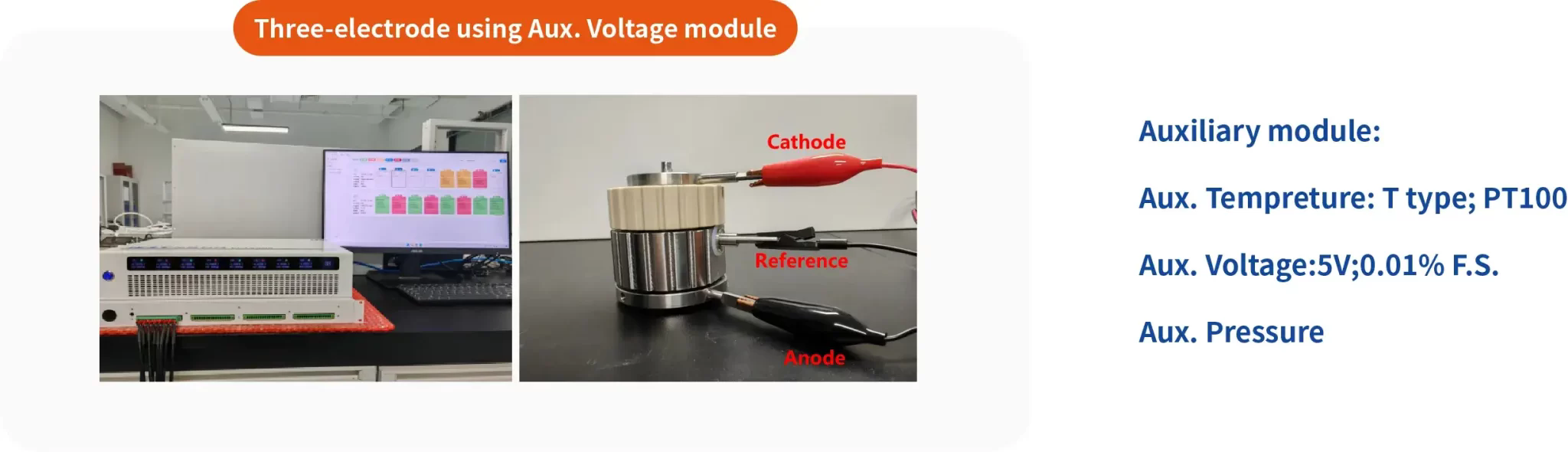

2. Supports a wide range of cell types, capacitor materials, half-cell, three-electrode, coin cell, and small-capacity testing.

7. Private cloud platform and cloud server backup ensure data security and confidentiality.

1. dQ/dV Analysis

2. Accurate DCIR

8. Cell Cycle Impedance Analysis

Description

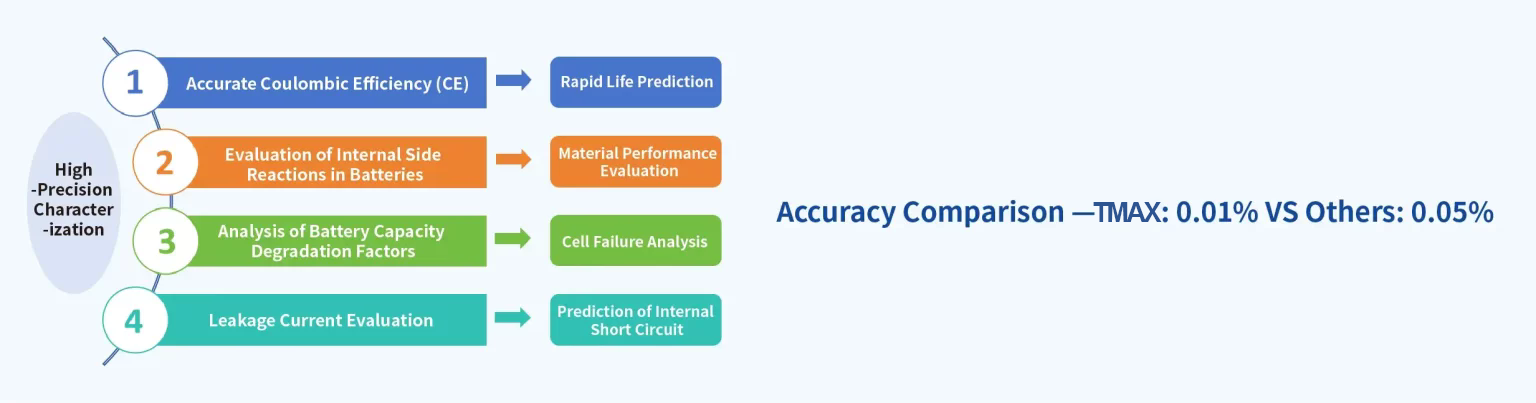

1. 0.01% High-Precision Current & Voltage Testing Electrochemical Analyzer

The battery cycler’s 0.01% testing accuracy can precisely measure the specific capacity of new materials and detect subtle side reactions during the initial stages of battery cycling, This allows for a comprehensive performance evaluation and lifetime prediction of the battery in a short period.

2. Innovative Solutions of TMAX

1) Provides accurate benchmark data for lifespan prediction, inventory efficiency, self-discharge, and micro-reaction testing, with voltage and current precision of 0.01%.

2) Supports a wide range of cell types, capacitor materials, half-cell, three-electrode, coin cell, and small-capacity testing.

3) Triple protection (software, hardware, firmware) ensures safe operation for both equipment and samples.

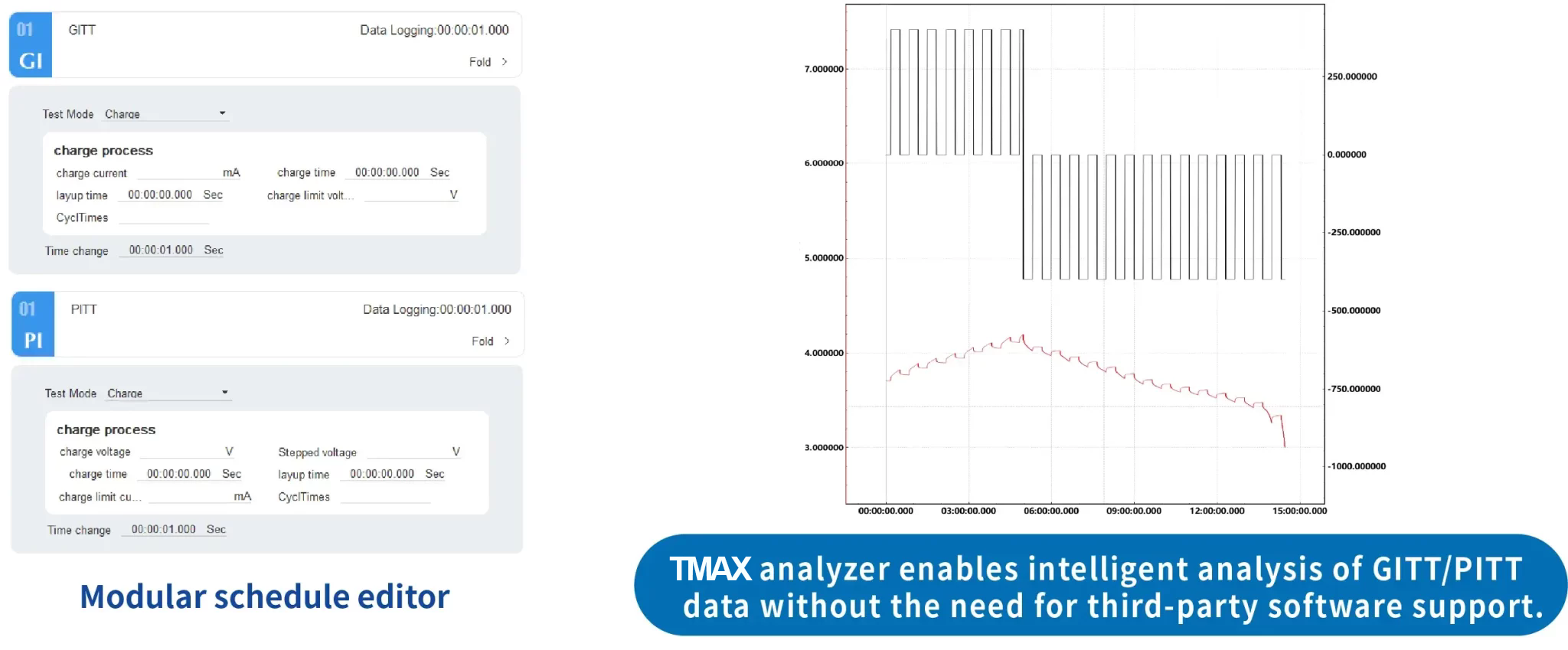

4) Supports electrochemical testing (GITT, PITT, CA, CP) with microampere-level current control.

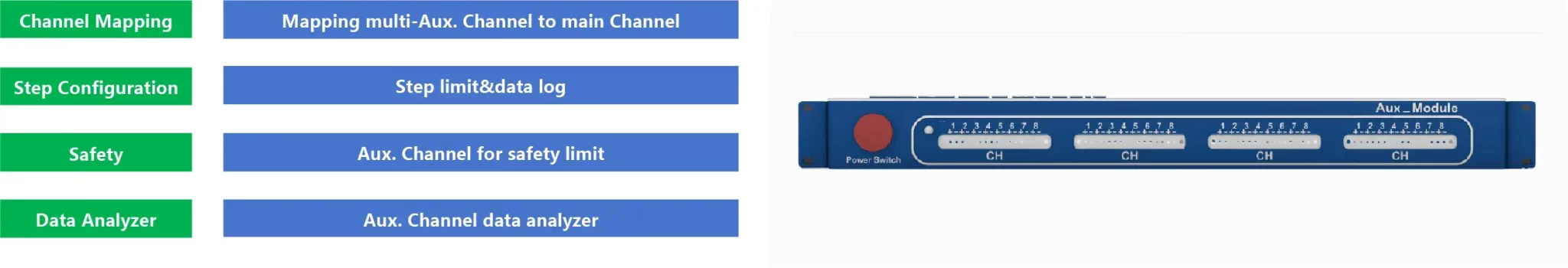

5) Flexible auxiliary channel integration for temperature control, surface temperature monitoring, three-electrode setups, and pressure detection.

6) Online calibration and independent operation of channels without interference.

7) Private cloud platform and cloud server backup ensure data security and confidentiality.

3. GITT/PITT Test

4. Auxiliary Channel

Application Cases

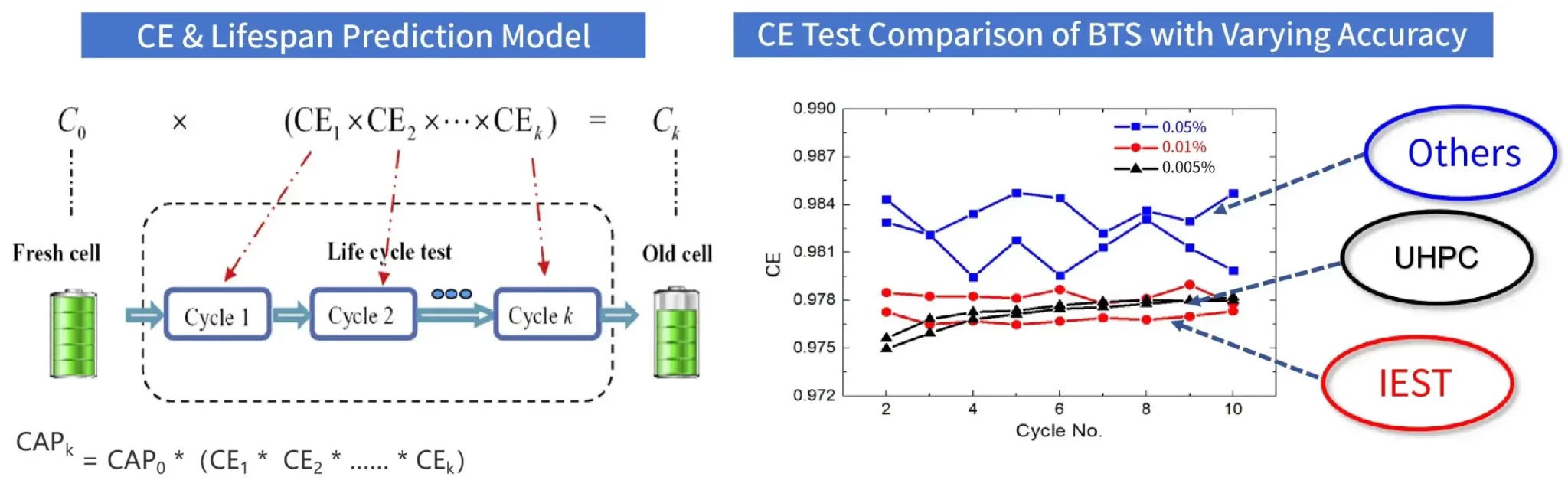

Case 1: Precise CE & Lifespan Prediction

For a 100Ah battery:

With an average CE test accuracy of 99.95%, after 500 cycles,CAPk=100*0.9995 500 =77.88Ah

With an average CE test accuracy of 99.955%, after 500 cycles, CAPk= 100*0.99955 500=79.85Ah

The difference is 1.97Ah, meaning the model accuracy differs by 1.97%!

1) High-precision CE testing allows for early performance assessment, enabling rapid battery lifespan prediction!

2) Lifespan prediction requires accuracy within 0.1% and noise

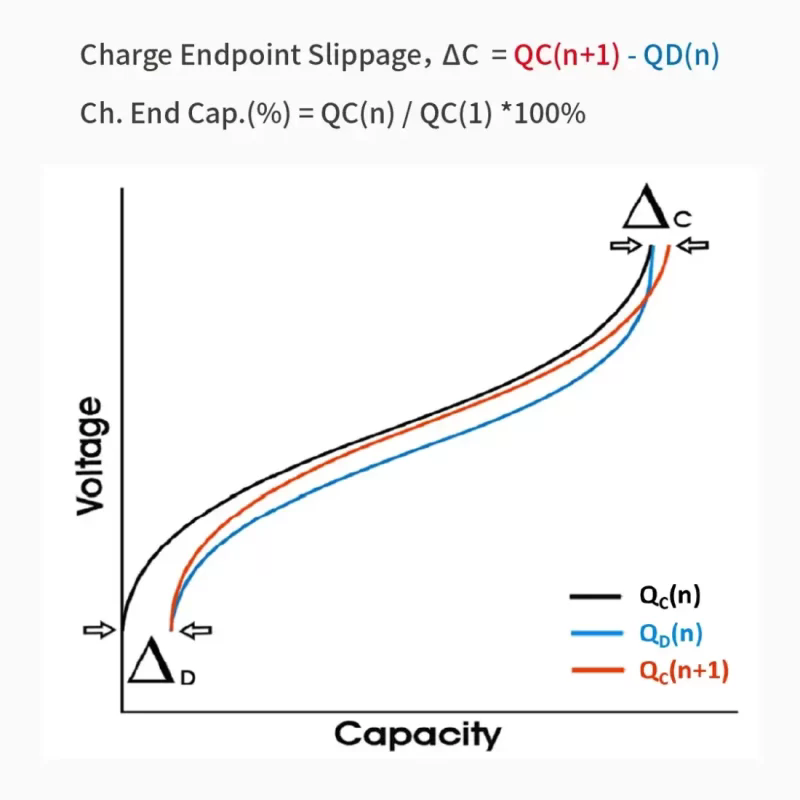

Case 2: Side Reaction & Material Evaluation

* ΔC or Ch. End Cap measurement requires high-precision charge-discharge equipment. Low accuracy will lead to inaccurate results.

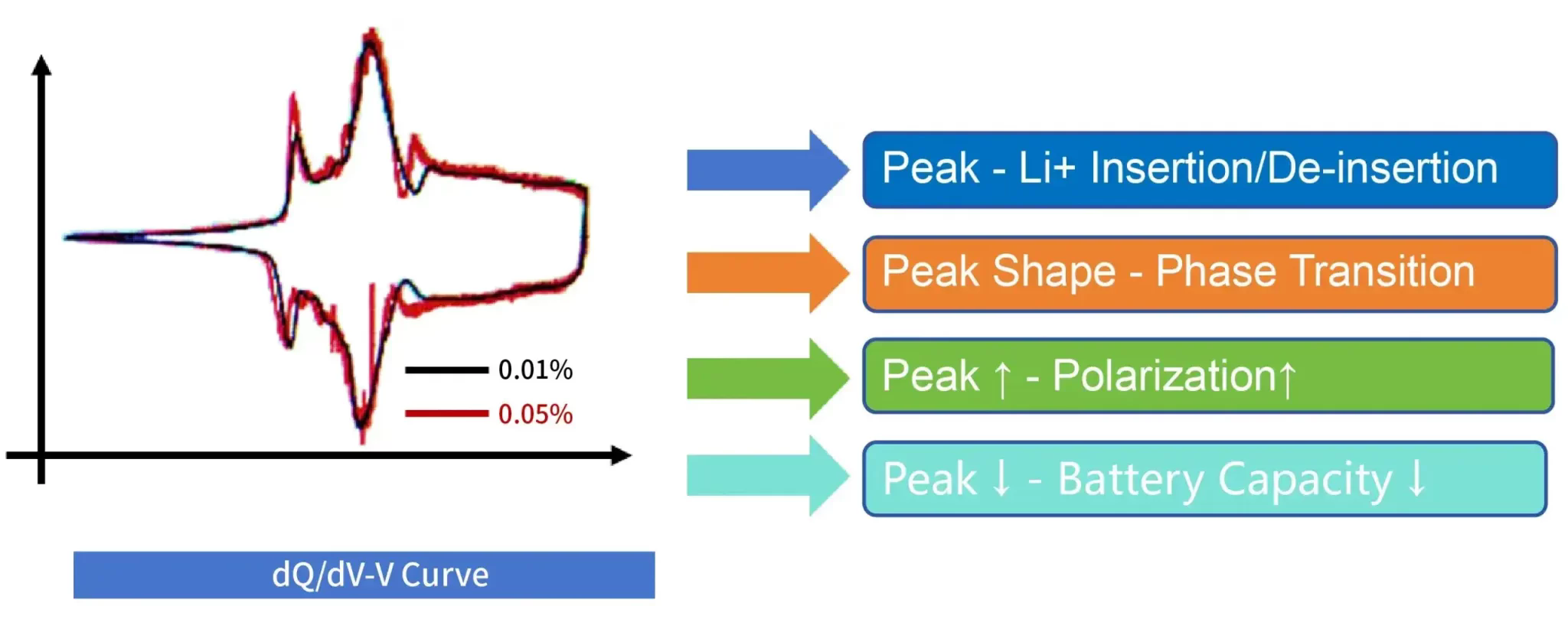

Case 3: Battery Capacity Decay Factor Analysis

* High-precision testers ensure smooth curves and capture small phase change peaks!

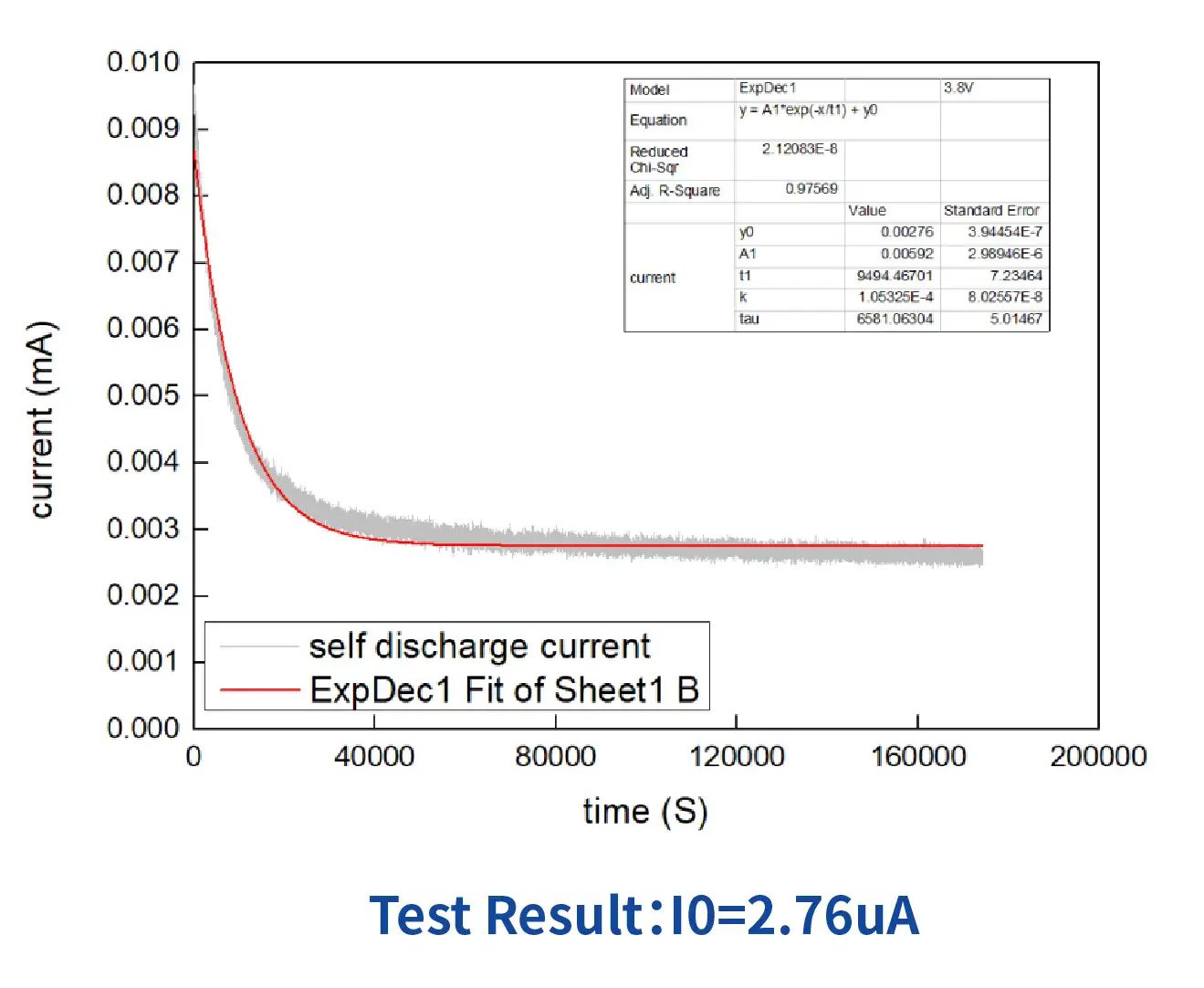

Case 4: Leakage Current

Charge to the target voltage, stabilize under constant voltage, and assess leakage current by the zero-current difference.

Test Plan:

1. Button Cell:

Electrodes: Ternary(фl4mm)vs. Lithium(ф20mm)

Capacity: 2mAh

Equipment: ECT6008-5V10mA

2. Test Process:

Constant current, constant voltage charging: 0.8mA,3.8V, for 72 hours.

* High-precision testers ensure accurate leakage current measurement.

Specifications

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com