- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Battery Impedance Tester Battery Consistency Screening

Model Number:

TMAX-BITCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Battery Impedance Tester Battery Consistency Screening

Features

1. Wide range of applicable cells, ranging from 1Ah to 1000Ah;

2. Fast EIS frequency sweep testing, with a frequency range of 1500Hz to 0.1Hz;

3. Compatible with OCV testing, DCR testing, constant current charge-discharge testing, etc.,

4. Battery Consistency Screening;

5. Dynamic fitting screening algorithm for batch screening;

6. Rapid compartmentalization, multi-channel coupling;

7. Convenient Operation.

Application

1. EIS testing for power batteries or energy storage batteries;

2. “Industrial grade” EIS applications;

3. Battery long cycle EIS testing;

4. The back end of the battery cell factory’s production line carries out consistency screening and abnormal battery detection;

5. Battery consistency assessment before battery pack preparation;

6. Rapid SOH evaluation of batteries prior to recycling and remanufacturing into Packs(Cascade Utilization);

7. Battery cell procurement quality consistency testing, etc.

Description

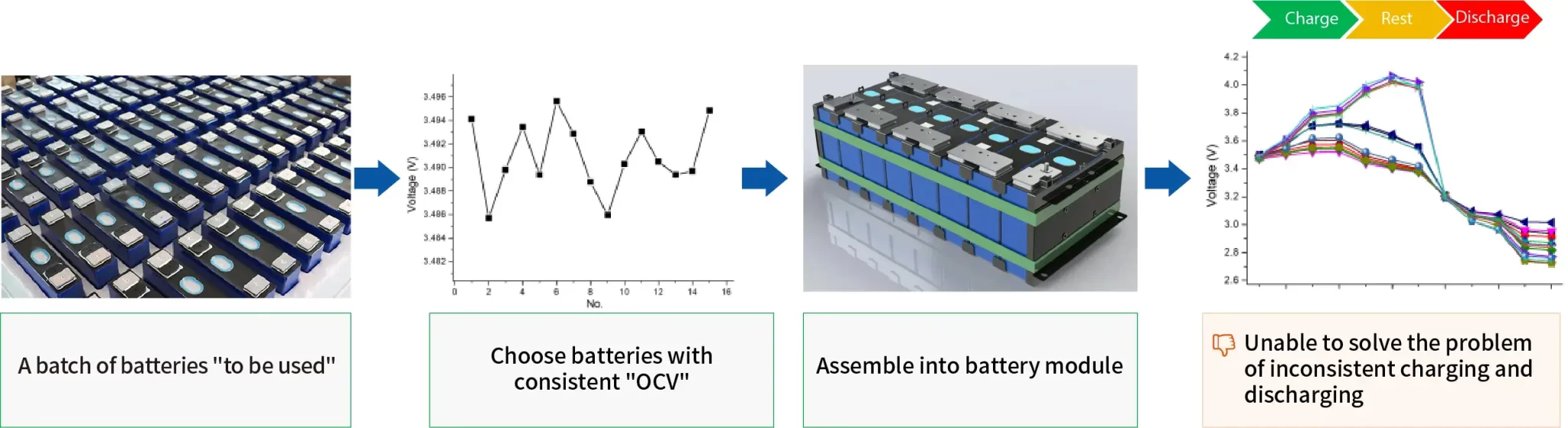

1. Background and significance of battery cell consistency testing before shipment

In new energy vehicles or energy storage power stations, lithium batteries are often used in the form of multiple paralel modules or packs. Therefore, high consistency requirements are placed on the battery cells in the same module or pack. Otherwise, thermal runaway may occur easily due to overcharging/overdischarging of a certain battery cell, leading to many after-sales problems.

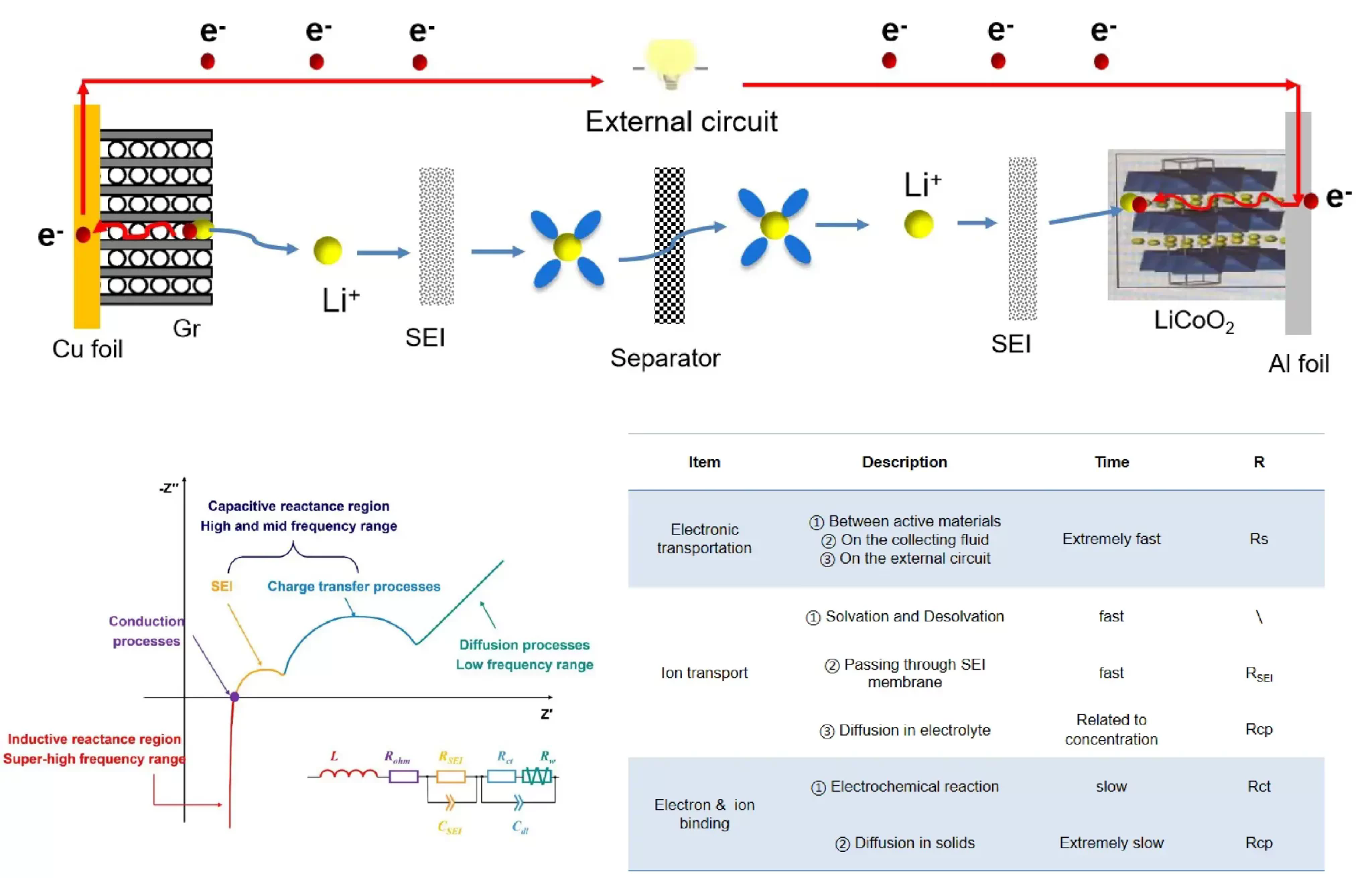

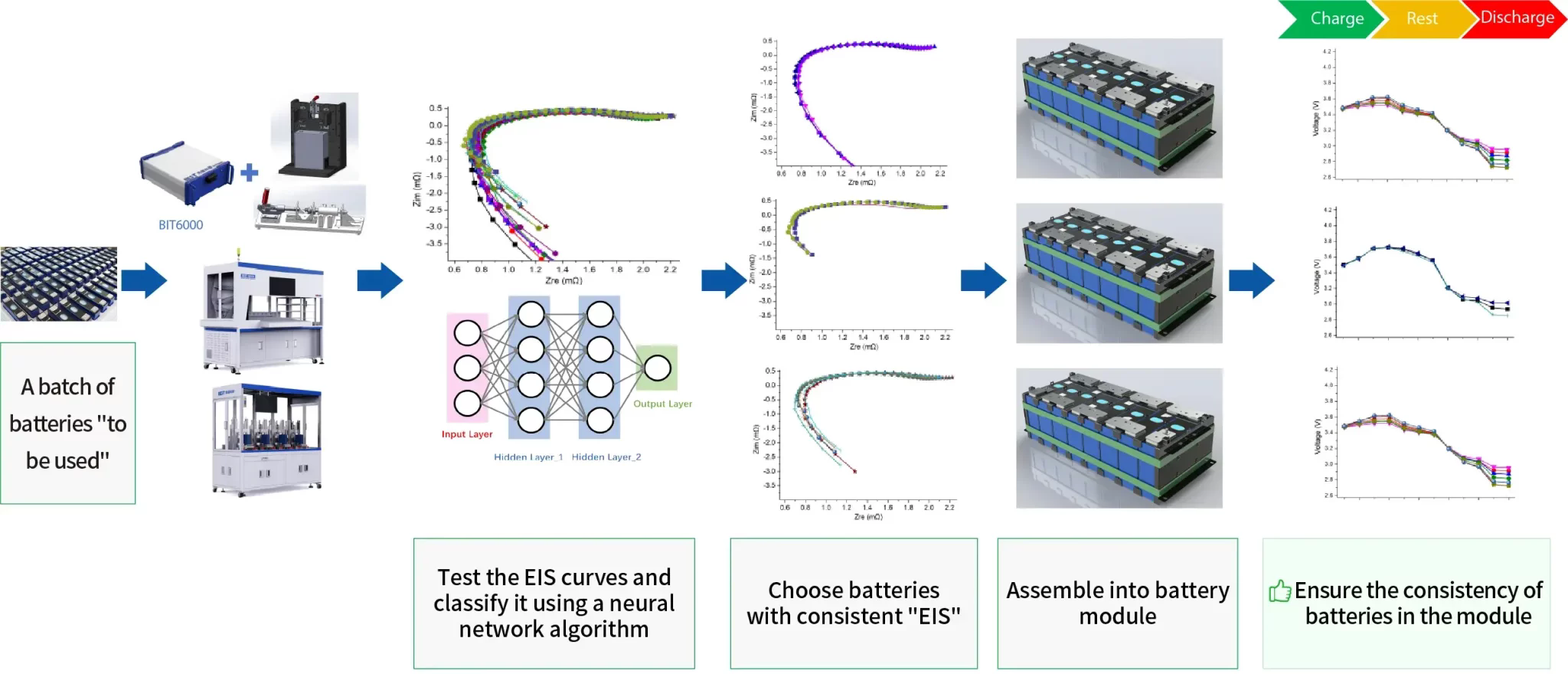

Electrochemical impedance spectroscopy (EIS) has good sensitivity and correlation with the SOC, SOH, internal temperature, internal short circuit, etc, of the battery celll. By usine fast EIS testing and neural network algorithm modeling, you can effectively screen the consistency othe battery cells and help the cascade utilization of the battery cells.

2. Creative Solution

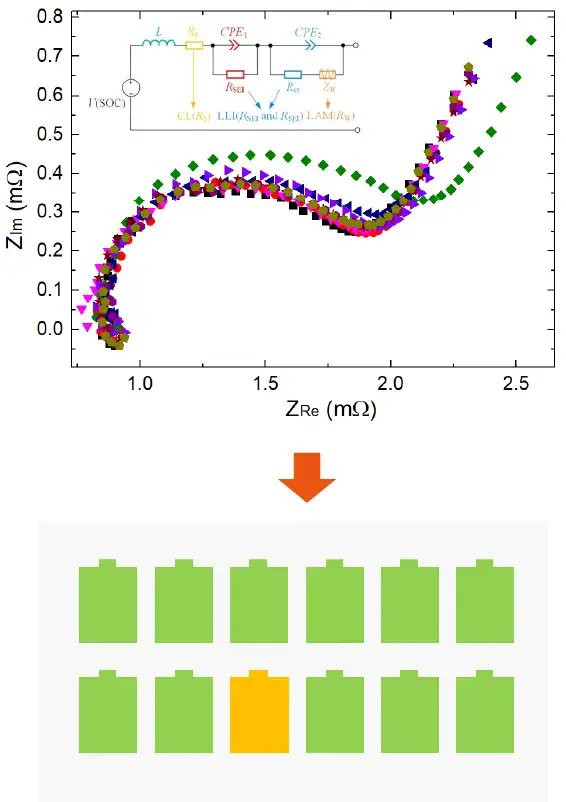

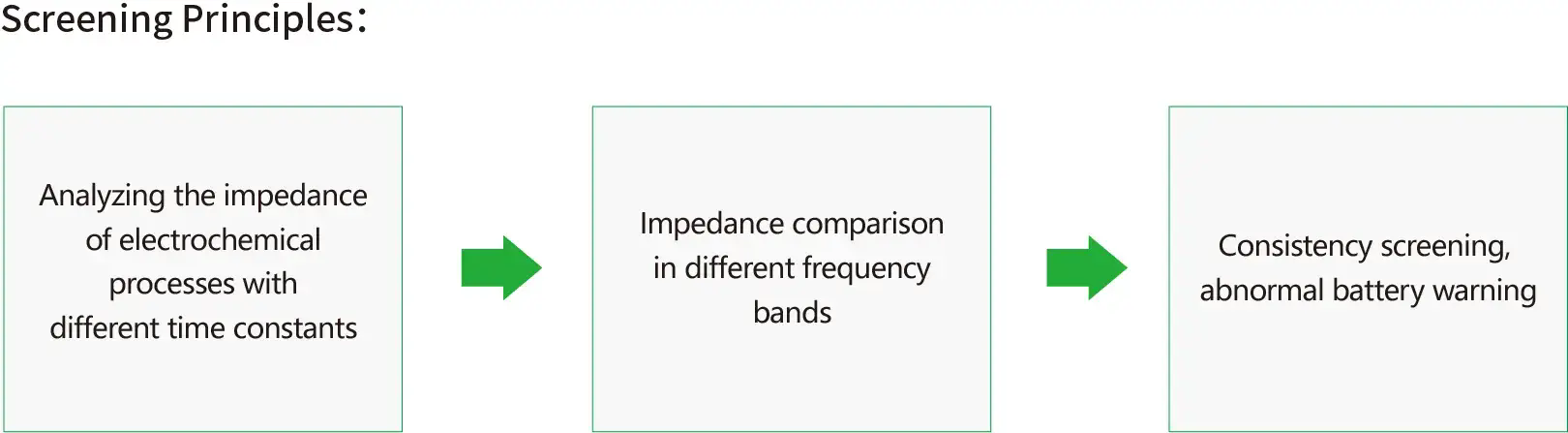

Electrochemical impedance spectroscopy (EIS) can be used to characterize the resistance of electrochemical processes with diferent time constants. Introducing EIS testing betore battery shipment or after battery delivery, and comparing the impedance differences between diferent batteres, can (1) screen the consistency of batteries; (2) find abnormal batteries; (3) help analyze the failure mechanism of batteries!

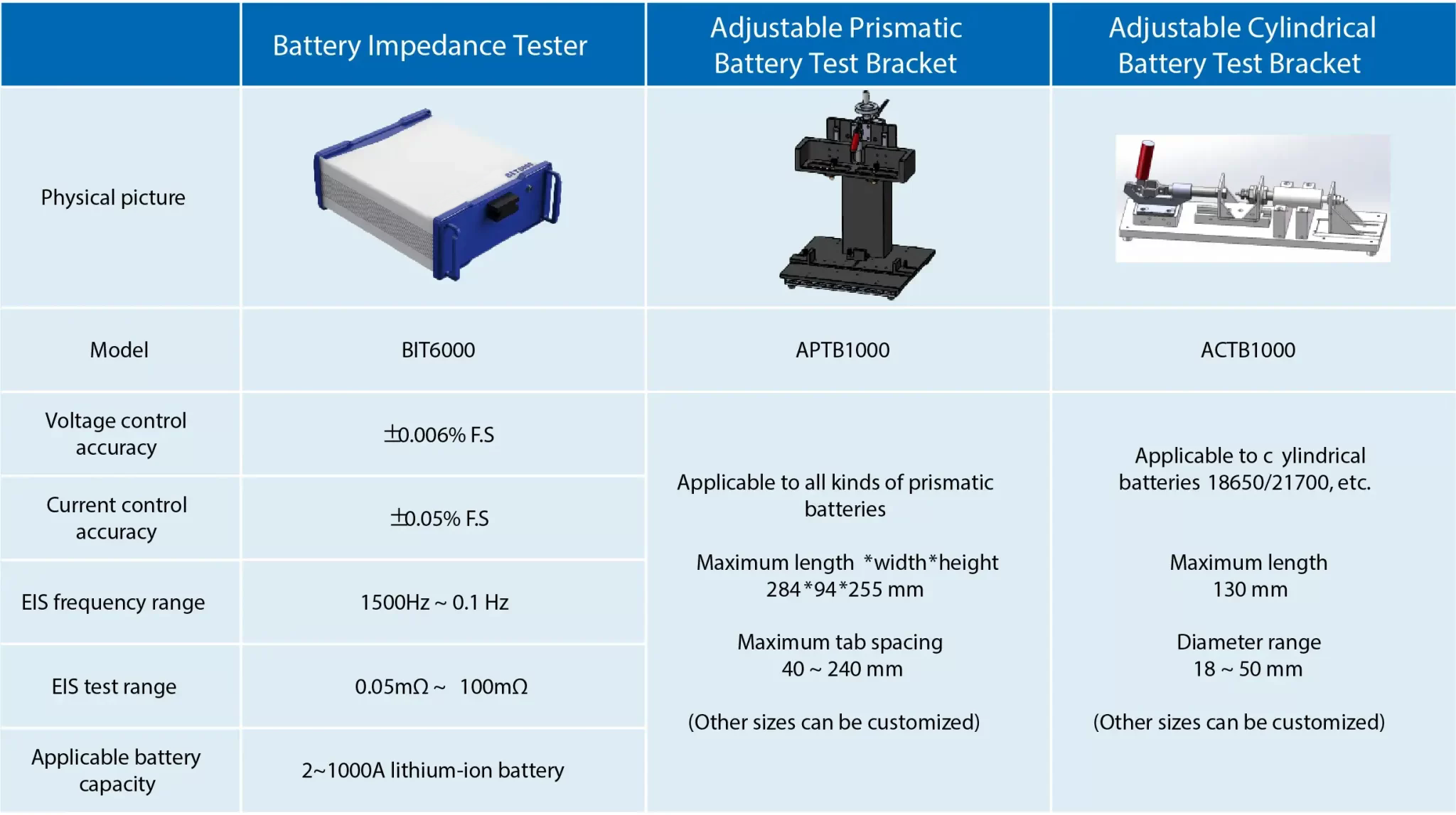

3. BIT6000 Introduction

Functions & Features

① Wide range of applicable cells, ranging from 1Ah to 1000Ah;

② Fast EIS frequency sweep testing, with a frequency rangeof 1500Hz~0.1Hz;

③ Equipped with OCV testing, DCR testing, constant currentcharge-discharge testing, etc.;

④ Battery Consistency Screening;

⑤ Dynamic fitting screening algorithm for batch screening.

Applications

1. Application scenario

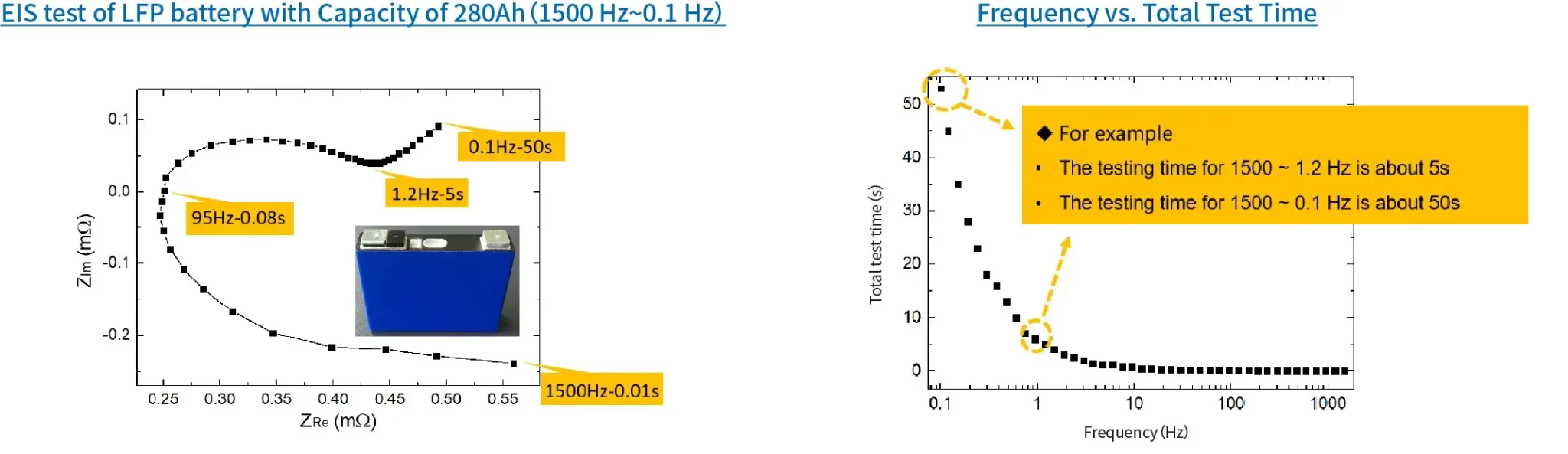

2. ElS Test of Battery With Large Capacity & Low Internal Resistance.

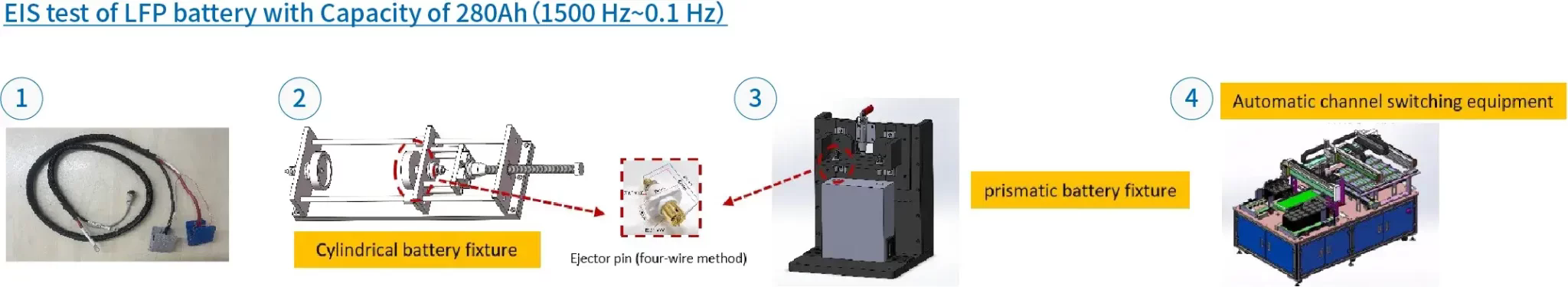

TMAX's BIT6000 can easily test the EIS of batteries with large capacity (2Ah~1000Ah) and low internal resistance (0.05mΩ~100mΩ). We also support customization various testing fixtures and automation testing equipment.

Note: The EIS test frequency range can be adjusted according to the production line progress and process section

3. Case 2

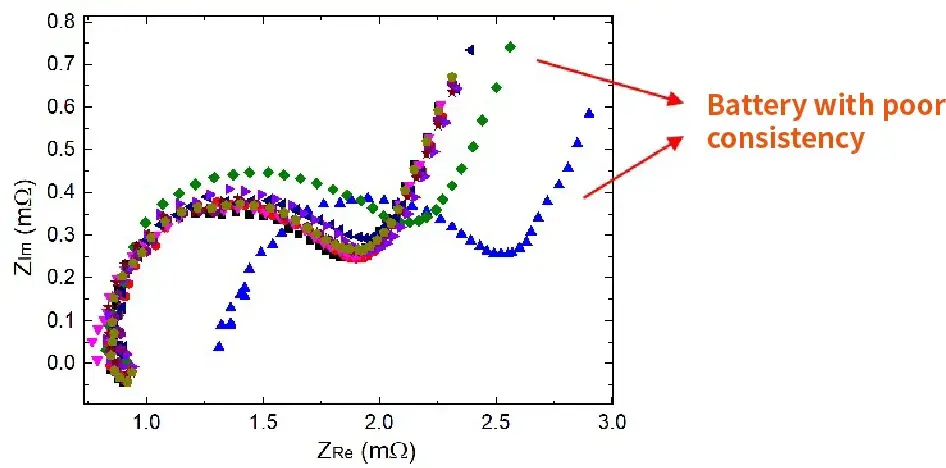

3.1 EIS screening is conducted on 30 prismatic cells with a capacity of 50Ah each (at 50% state of charge) over a frequency range from 1500Hz to 0.1Hz.

Especially for the battery represented by the green line, its impedancein the high-frequency region is consistent with other batteries, and only the impedance in the medium and low-frequency regions has a large difference. In this case, if only the electronic resistance or 1000Hz impedance is tested, it cannot be effectively distinguished, but swept frequency EIS can effectively screen and identify!

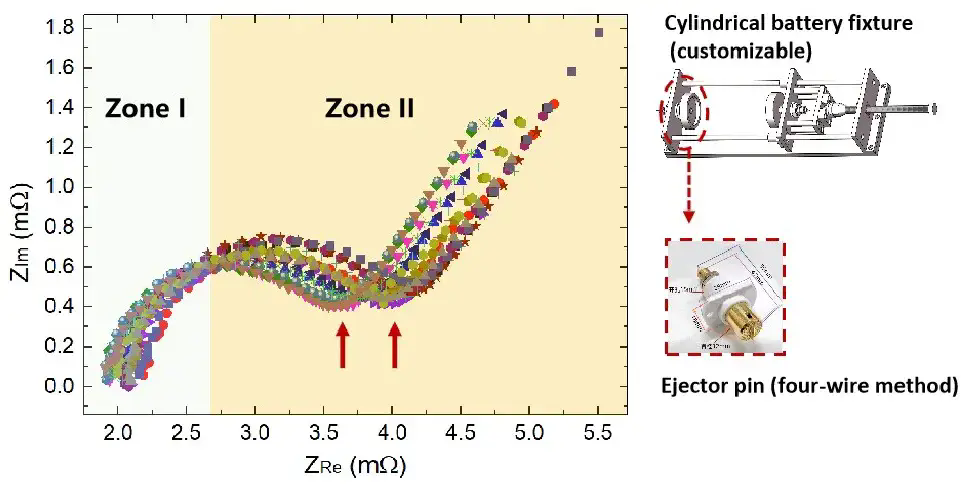

3.2 EIS screening is conducted on 40 cylindrical cells with a capacity of 30Ah each (at 6.5% state of charge) over a frequency range from 1500Hz to 0.1Hz.

In zone Ⅰ: For ohmic impedance and SEI impedance, the 30 batteries are distributed relatively concentratedly, with no obvious differences; In zone Ⅱ: Rct is divided into two concentrated areas, indicating that there are certain differences in the ionic impedance of the 40 batteries, which will affect the capacity after long cycles.

4. EIS Test Before Module Assembly (Battery Consistency Screening)

1) For battery manufacturers producing and assembling modules/packs, EIS testing can be used to check the quality and consistency of battery in the same module/pack.

2) For EV/energy-storage manufacturers sourcing batteries externally, EIS testing ensures incoming battery quality to maintain the consistency of battery in the same module/pack.

Traditional Battery Sorting Method:

TMAX's Innovative Battery Sorting Method:

Specifications

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com