- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

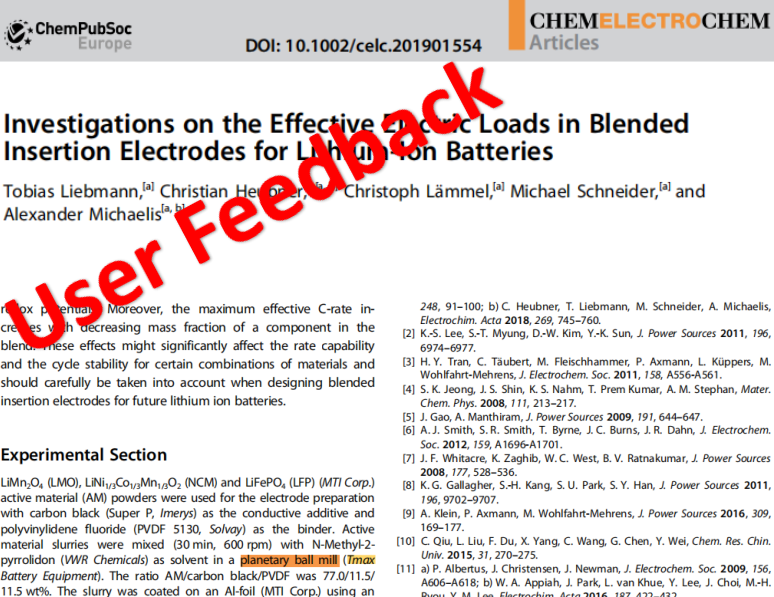

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

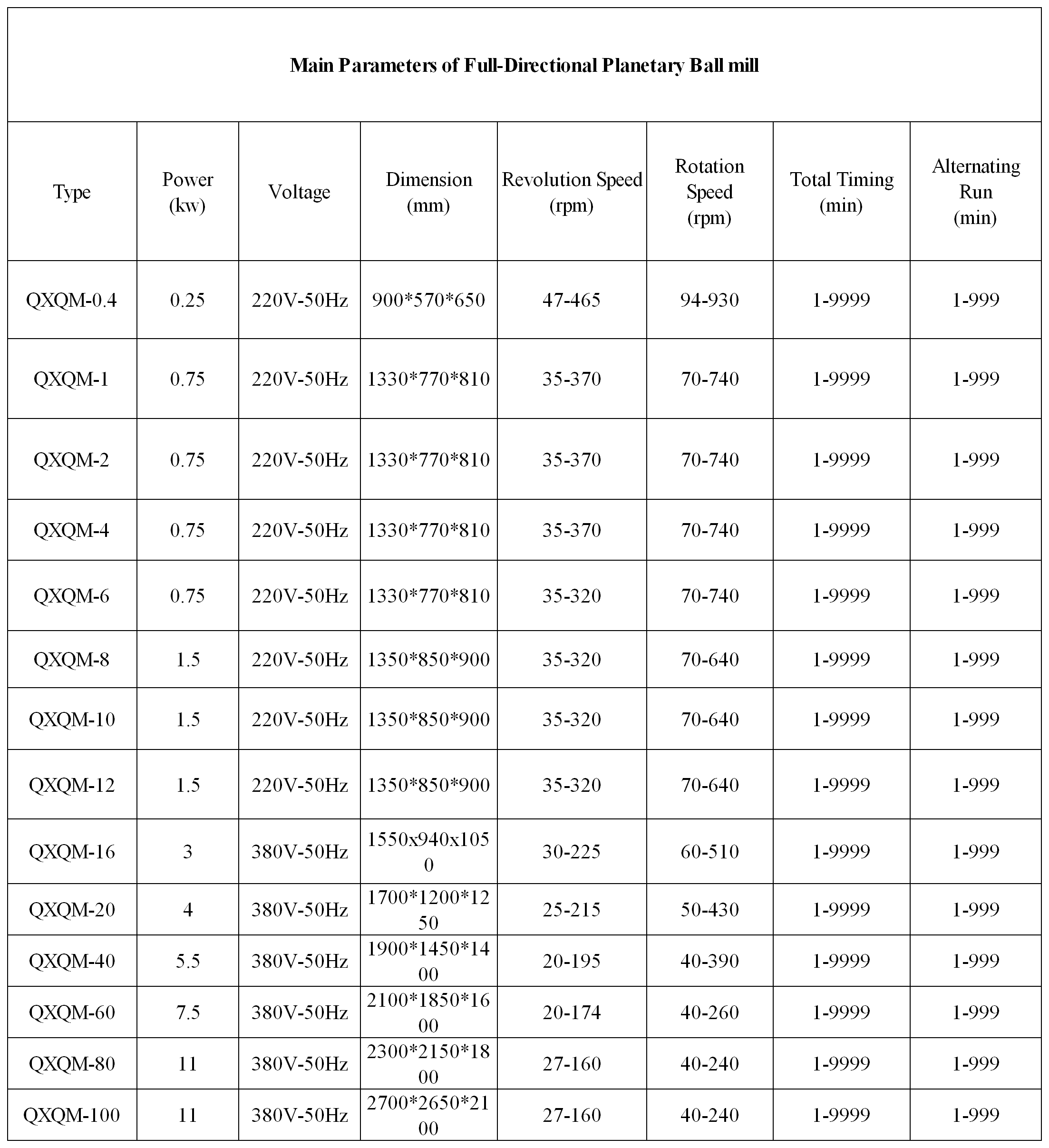

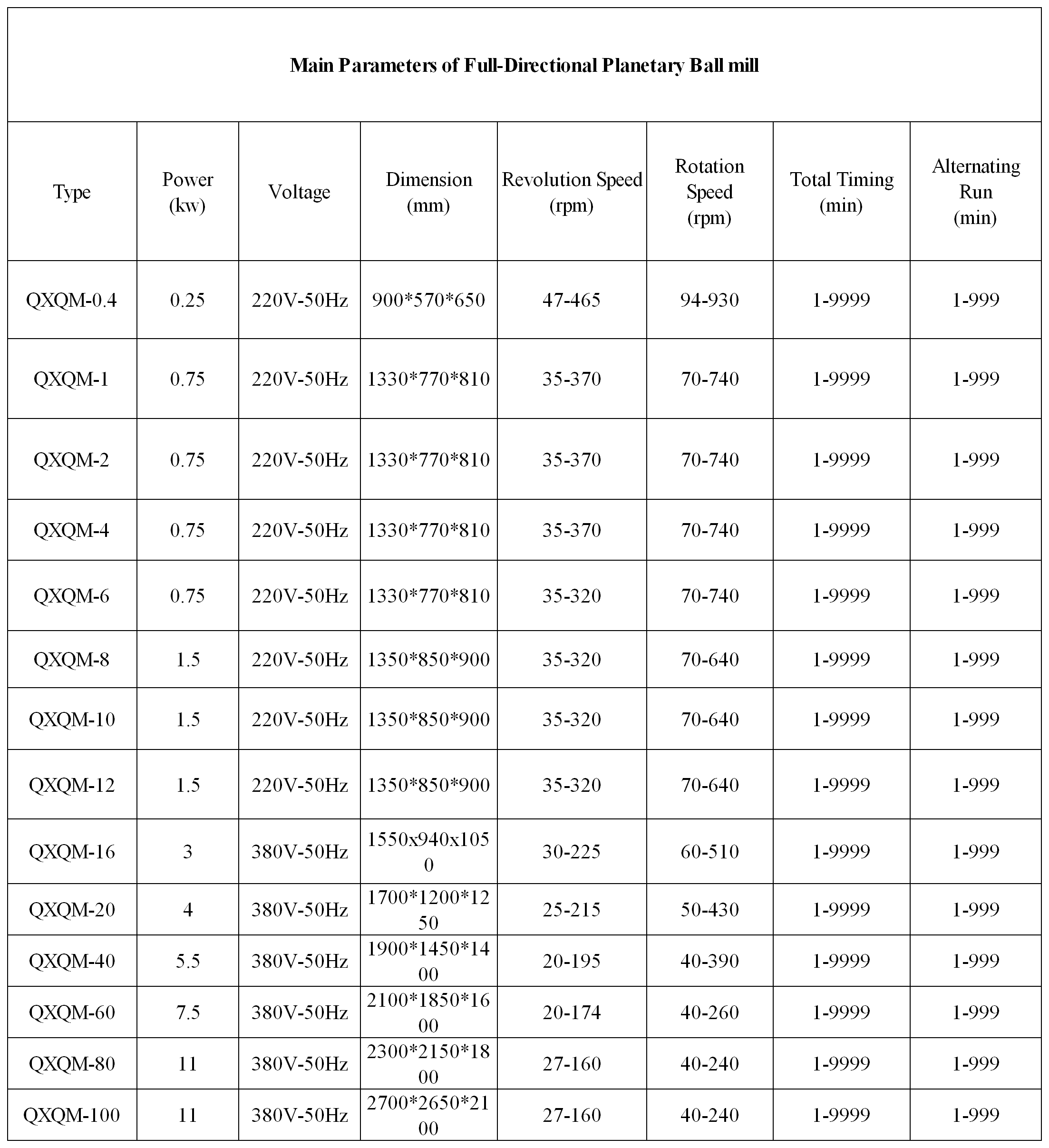

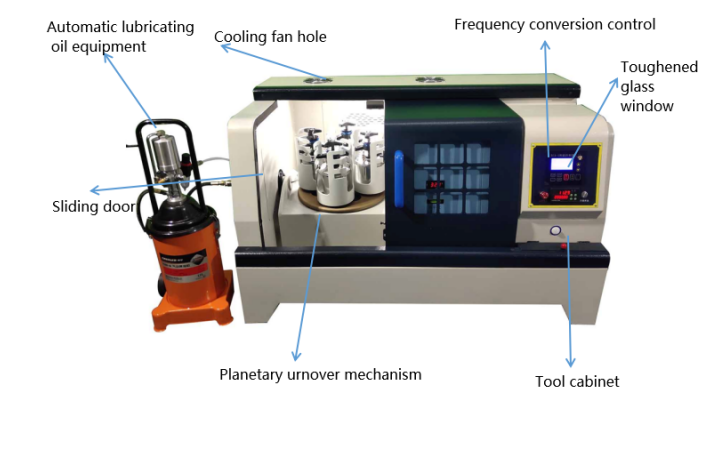

Lab 0.4L-100L Vertical Omni-directional Planetary Ball Mill

Model Number:

TMAX-QXQMType:

Planetary Ball Mill MachineInput Power:

0.37KWDimension(L*W*H):

570*300*450mmMax. Loading Capacity:

0.2L-0.4LNet Weight:

35KGCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Lab 0.4L-100L Vertical Omni-directional Planetary Ball Mill

Overview

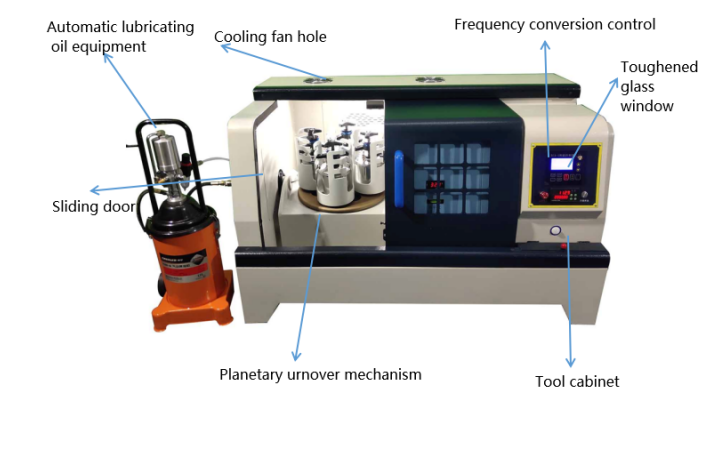

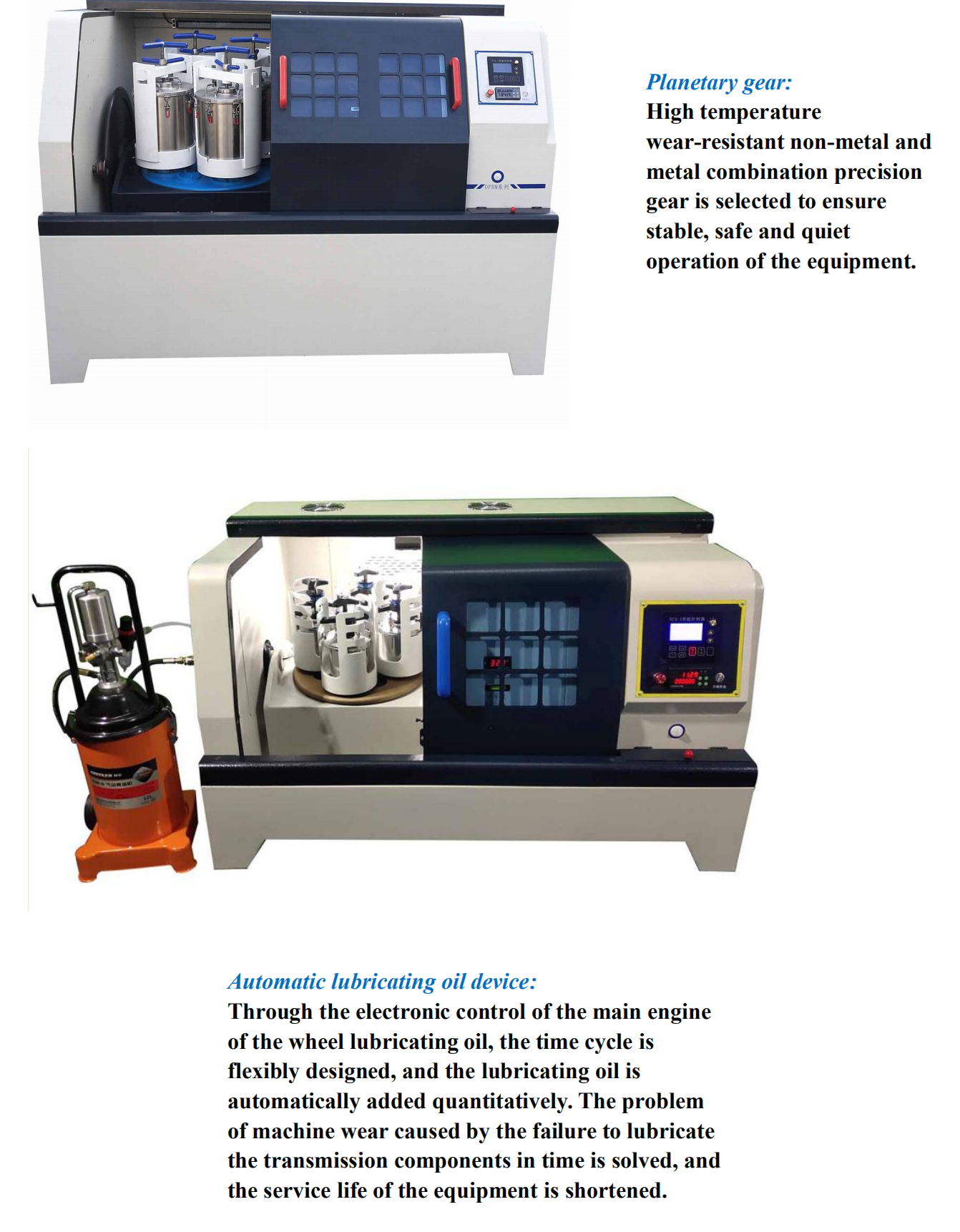

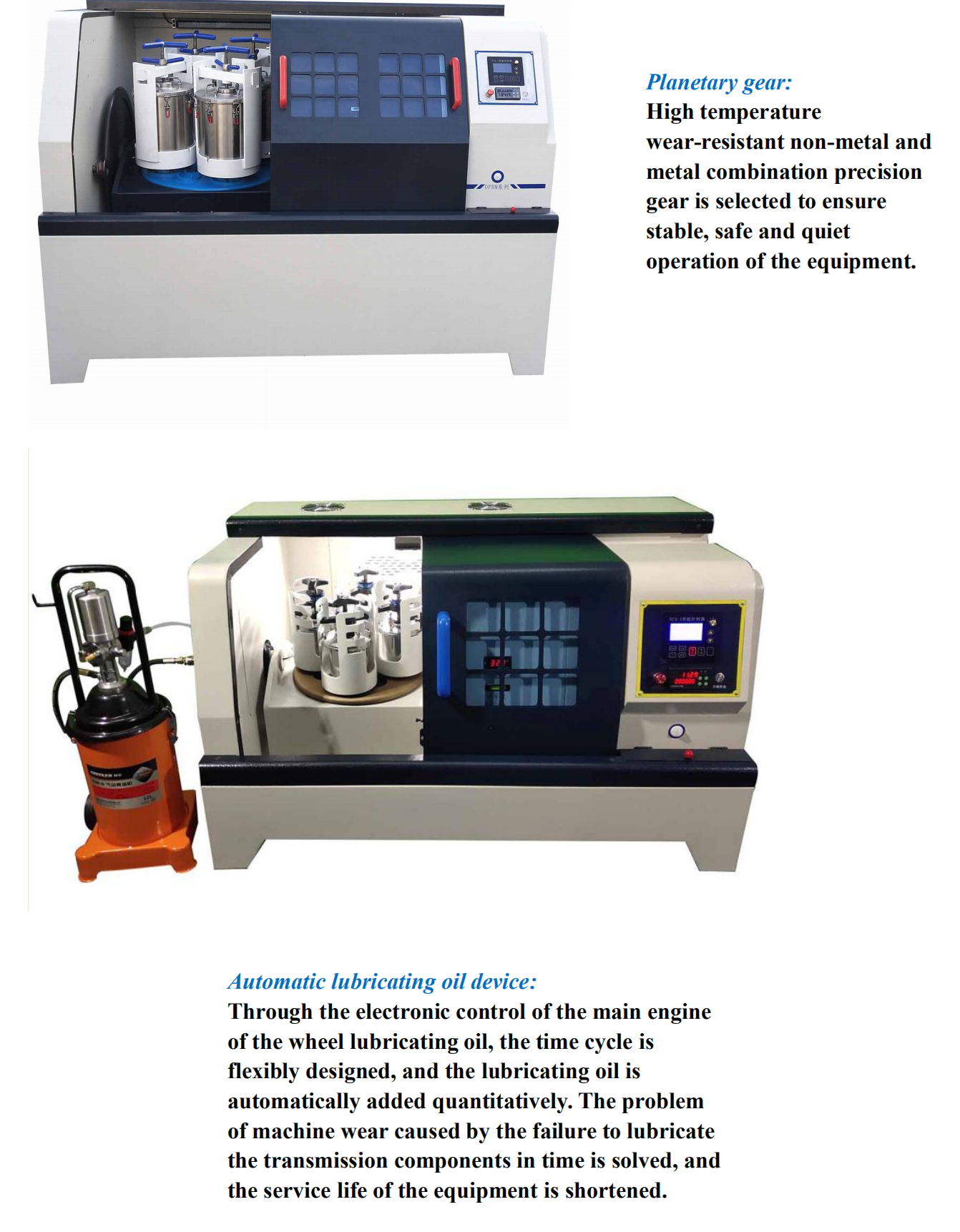

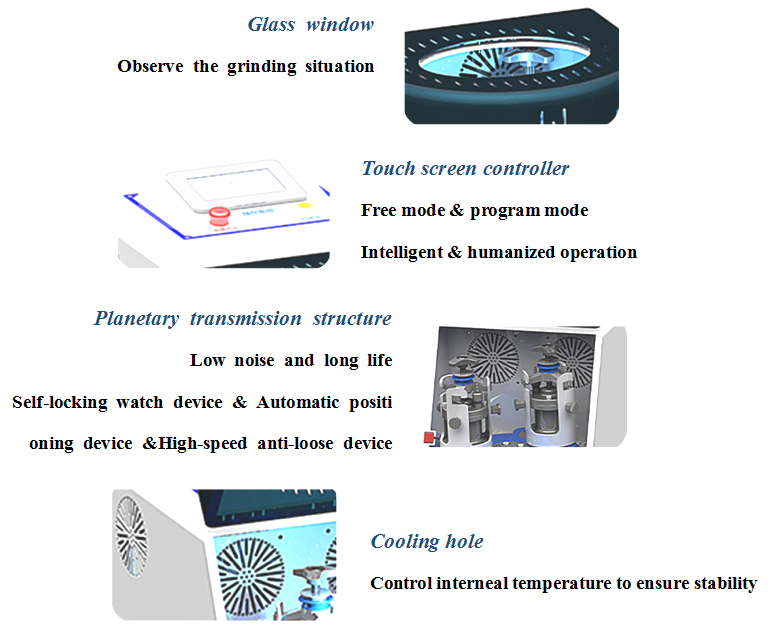

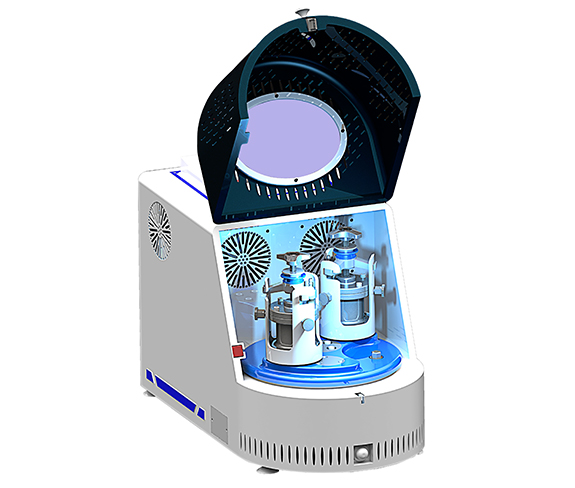

The omni-directional planetary ball mill is based on the vertical ball mill, adding planetary rotation and overturning function. When the material in the planetary plate and ball mill jar is planetary, the ball can also do 360 ° overturning in a fixed space, so as to realize the multi-dimensional movement of the ball and material in the ball mill jar, and improve the disorder movement of the ball and material. There is no dead angle grinding for the whole material in the grinding tank, which makes the grinding material more uniform, and can effectively solve the problems of some materials sinking to the bottom and sticking to the tank.

Features:

1. The equipment is light, with a push-pull door, which is convenient for operation.

2. The shell adopts high precision laser cutting, CNC bending forming, elegant and exquisite, high-end and stable planetary disk, the structural components are processed by numerical control processing technology, and the metal heat treatment process of air infiltration is used to ensure the rotational speed of shaft parts, wear resistance and prevent shaft breakage.

3. High temperature and wear-resistant non-metal and metal precision gear is adopted for rotating gear, and lubricating grease is used for lubrication.

4.Automatic lubricating oil device:

Through the electronic control of the main engine of the wheel lubricating oil, the time cycle is flexibly designed, and the lubricating oil is automatically added quantitatively. The problem of machine wear caused by the failure to lubricate the transmission components in time is solved, and the service life of the equipment is shortened.

Specifications

|

Drive Mode |

Gear drive |

|

Operate Mode |

Two or four grinding jars working together |

|

Maximum Loading Capacity |

2/3 of the total volume of milling jars |

|

Each Jar’s Volume |

0.1L-25L; Total:0.4L-100L |

|

Feeding Size |

Soil material≤10mm,other materials≤3mm |

|

Output Granularity |

Smallest granule reaches 0.1μm |

|

Rotational Speed Ratio |

1:2 |

|

Max.Continuous Operating Time |

48 Hours |

|

Materials of Jar |

Stainless steel.agate,nylon,corundum,zirconia,etc |

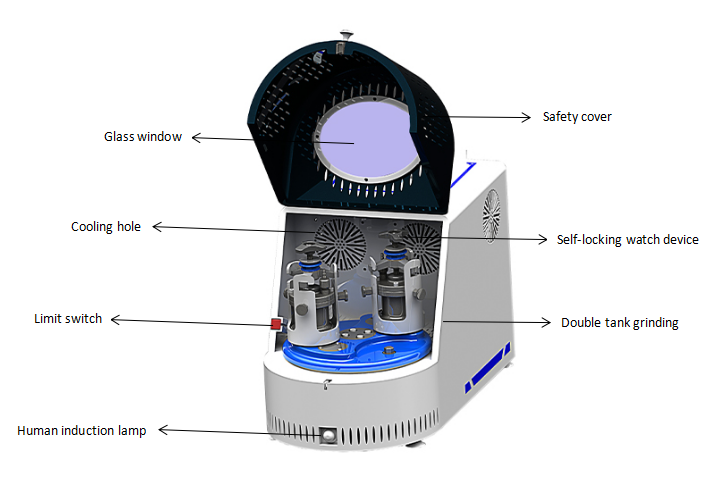

Product Images

Product Images

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com