- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Lab 65T Split Electric Cold Isostatic Press with Plexiglass Doors

Model Number:

TMAX-PCD-65JCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Lab 65T Split Electric Cold Isostatic Press with Plexiglass Doors

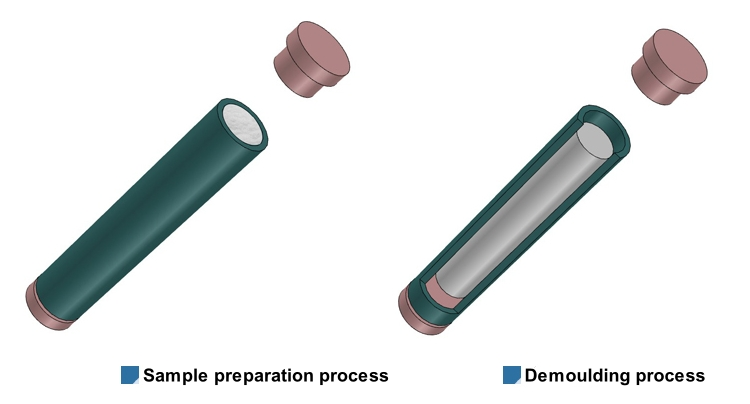

Mold diagram

Mold operation diagram

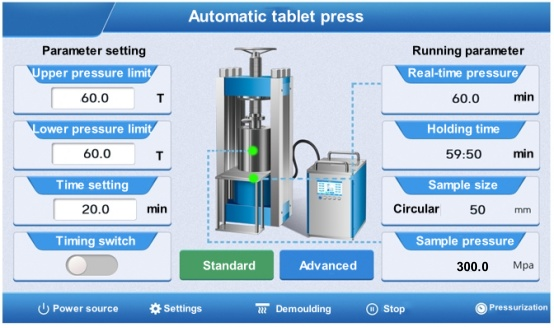

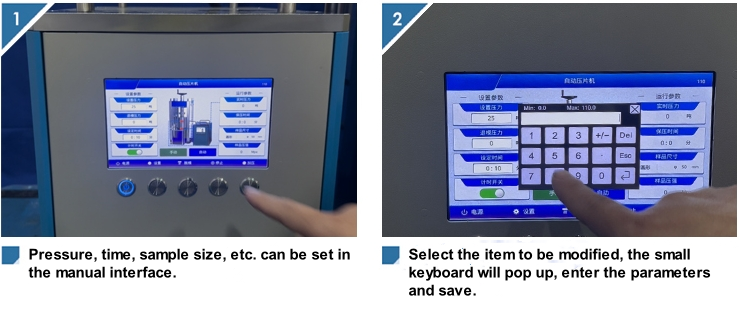

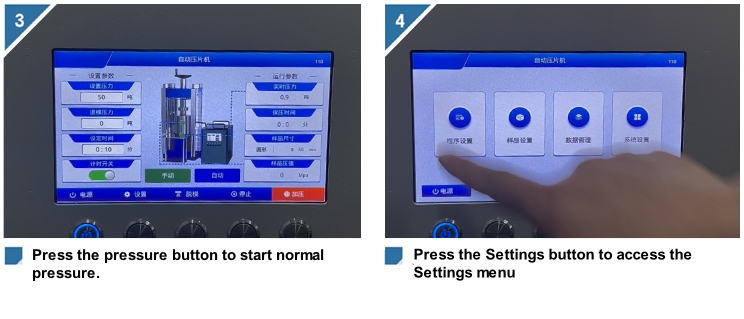

Operation interface (Manual mode)

Standard interface: Various parameters, pressure, demoulding, time, sample size, etc. can be set separately on this interface.

Pressurization button: Press according to the parameters set on the interface.

Stop button: Press the stop button during the pressurization process to stop the pressurization.

Demoulding button: Press the demoulding button to release the sample according to the demoulding pressure.

Timing switch: The timing function can be turned on and off.

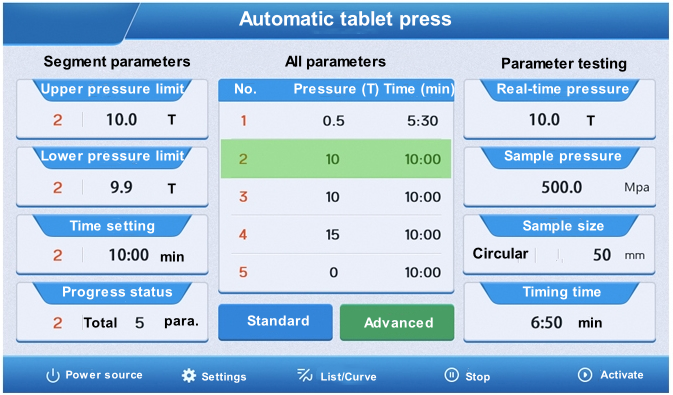

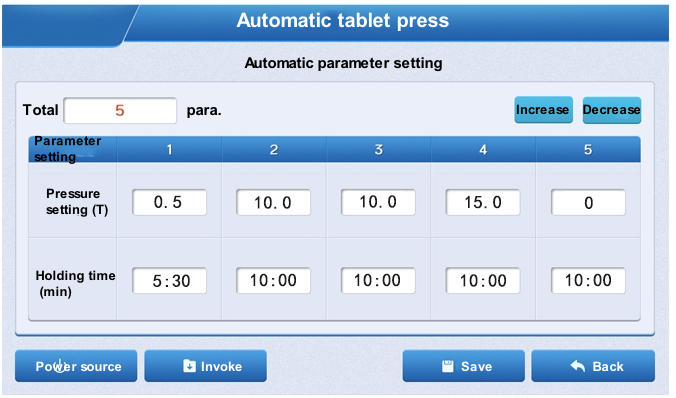

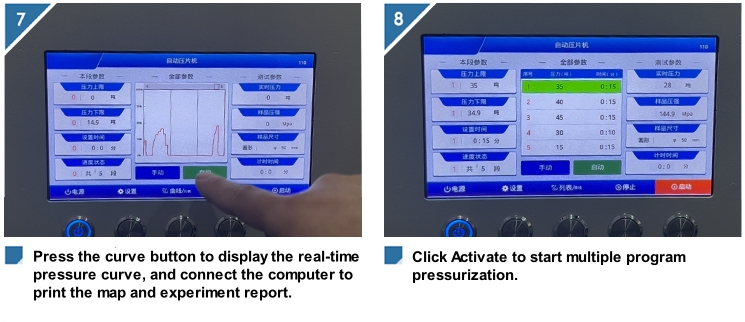

Operation interface (Automatic mode)

Activate button:It can be pressurized according to the multi-stage pressurization program.

Stop button: During the pressurization process, you can stop the pressurization process.

List/Curve: The current display state can be switched between list and curve

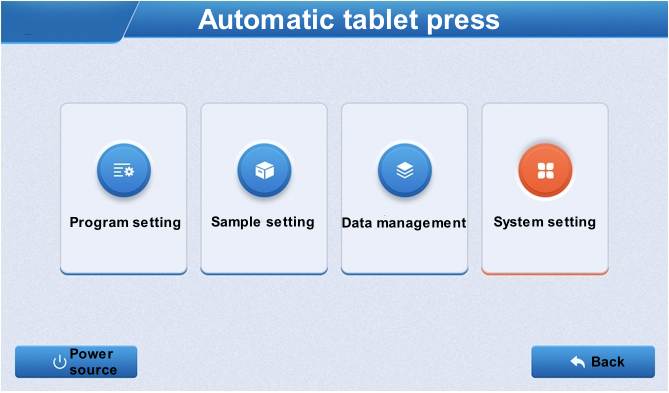

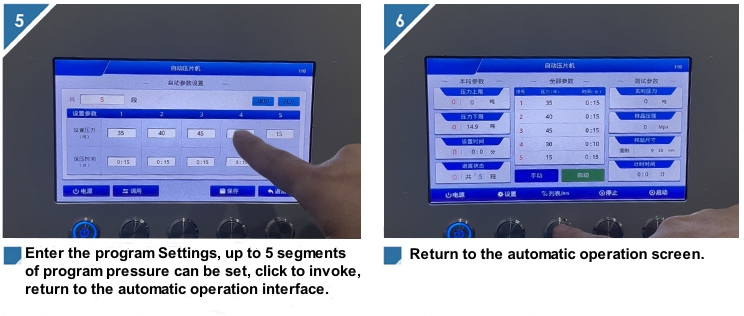

Setting interface

Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

Program Settings:Multi-stage pressure procedures and pressure holding times can be set.

Sample setting: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

Data management: Previously saved data records can be invoked and modified..

System Settings: Administrators can set various parameters, enter the password "666"

Setting interface

Multi-segment program Settings: Up to 5 segments of pressurized programs can be set.

Invoke button: Invoke the set parameters to the automatic operation interface for pressure.

Save button: Save the set parameters to the database for later invocation.

Back button: Returns to the Settings screen

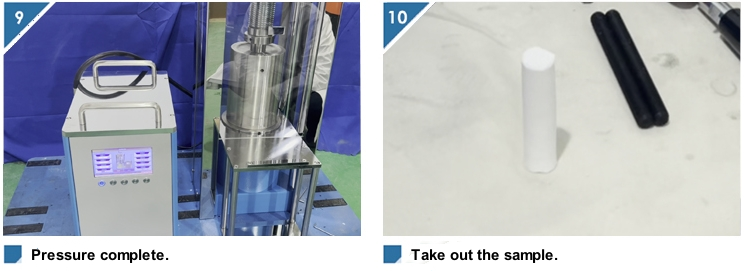

Operation procedure

Technical parameter

|

Instrument type |

PCD-65J |

|

Pressure range |

0-65T |

|

Piston diameter |

Chrome plated cylinder Φ160mm(d) |

|

Pressurization process |

Programmed pressure - programmed pressure retention - timed pressure relief |

|

Holding time |

1 s to ∞ s |

|

Pressure conversion |

The program automatically converts the pressure of the sample |

|

Liquid crystal display |

7-inch LCD screen |

|

Equipment protection |

Steel plate protection with plexiglass doors |

|

Isostatic pressure |

0-300MPa |

|

Isostatic pressure |

Φ50x150mm(MXN) 0-300MPa |

|

Isostatic pressure |

Φ40x150mm(MXN) 0-500MPa |

|

Space size |

220x400mm(MXN) |

|

Overall dimension |

700x450x1050mm(LxWXH) |

|

Equipment power supply |

1500W(220V/110 can be customized) |

|

Equipment weight |

350kg |

|

Powder press size diagram |

|

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com