- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

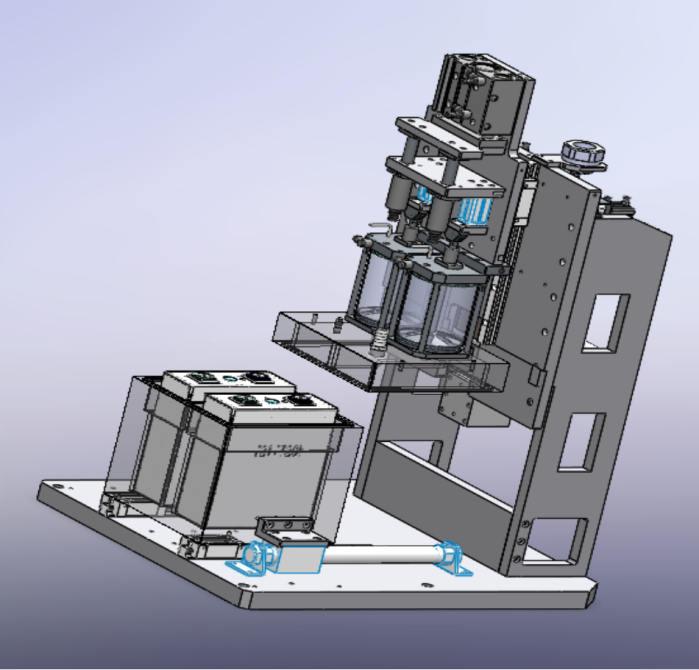

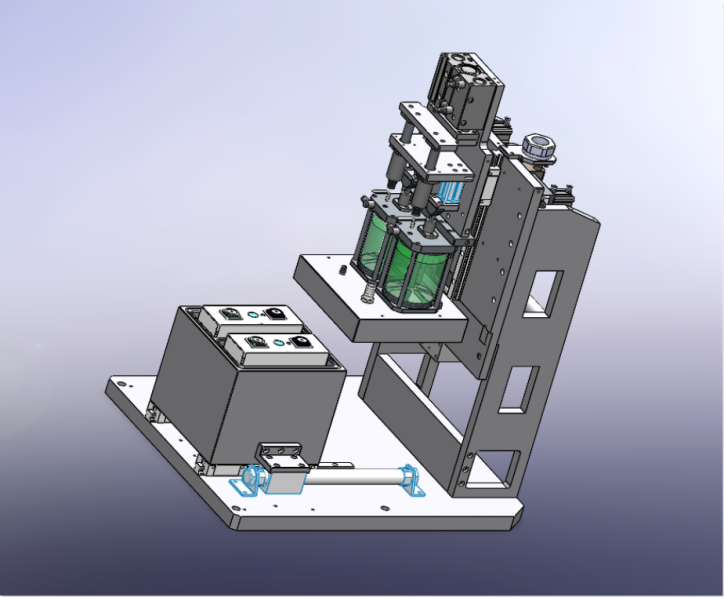

Lab Dual-station Prismatic Cell Electrolyte Vacuum Filling Machine Glovebox Compatible

Model Number:

TMAX-W-ZYCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

1. Equipment Functions:

Used for the electrolyte filling of prismatic cells.

2. Workflow Overview:

- Manually place prismatic cell into fixture.

- Start the equipment.

- Press down the top rod of the liquid storage cup.

- Injection starts inside the electrolyte storage cup.

- Fixture positioning.

- Move the slide to the absorption box.

- Vacuum starts inside the box after sensing this position.

- Open the sealing rod.

- Electrolyte enters the battery through the electrolyte storage cup.

- Vacuum and nitrogen alternate until all electrolyte is absorbed in the electrolyte storage cup.

- Open the absorption box.

- The absorption box returns.

- Manually remove the prismatic cell after electrolyte filling.

3. Technical Parameters

3.1. Compatible cell dimensions:

|

Item |

Specification |

Cell |

|

Thickness T (mm) |

30-80 |

|

|

Width W (mm) |

180-180 |

|

|

Height L (mm) |

90-220 |

Please note that this equipment is tailored for a single prismatic cell size within the specified range. However, by adjusting or modifying certain parts and components, this machine can accommodate other prismatic cell sizes (note that an extra quote is needed for the new fixtures required for different cell sizes).

3.2. Main Components Configuration

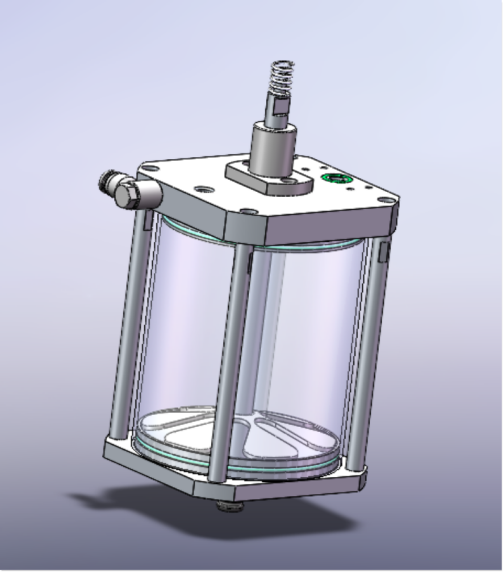

Injection absorption structure diagram

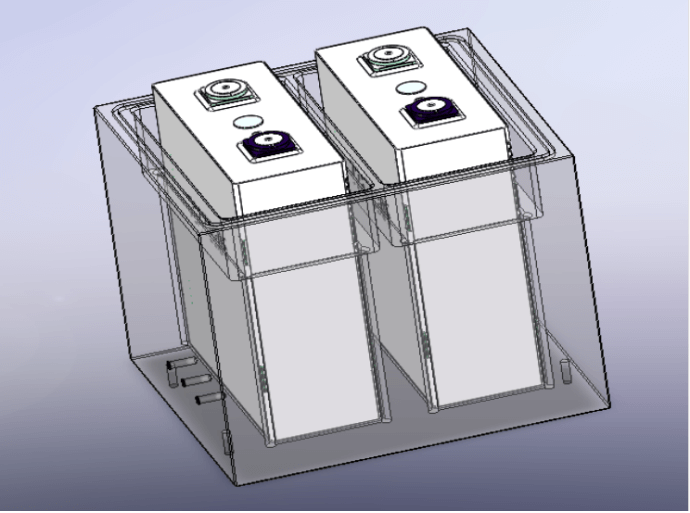

Absorption box

Electrolyte storage cup

4. Main Components Brands and Spare Parts

Main Component Configuration

|

No. |

Item name |

Brand |

|

1 |

PLC |

Xinje or equivalent brand |

|

2 |

Touch Screen |

Xinje or equivalent brand |

|

3 |

Pressure Reducing Valve |

AirTAC or equivalent brand |

|

4 |

Solenoid Valve |

AirTAC or equivalent brand |

Random Parts

|

No. |

Item name |

Spec |

Quantity |

|

1 |

O-ring EPDM Seal |

Inner diameter 86, wire diameter 2, O-ring (EPDM) |

2 |

|

2 |

O-ring EPDM Seal |

Inner diameter 9.8 ± 0.20, wire diameter 2, O-ring (EPDM) |

1 |

|

3 |

X-shaped Seal |

X-shaped seal (wire diameter 2.62 - inner diameter 9.19) (EPDM) |

1 |

|

4 |

X-shaped Seal |

X-shaped seal (wire diameter 1.78 - inner diameter 9.52) (EPDM) |

1 |

|

5 |

Custom Seal |

Outer diameter 12, inner diameter 3, height 12 (EPDM) |

2 |

5. Installation Environment Requirements

5.1. Power Supply:

Voltage: AC220V, 50Hz

Voltage Fluctuation Range: ±10%

Total Power Consumption: Approx. 0.5KW

5.2. Compressed Air:

Pressure Range: 0.25~0.75Mpa

Air Pressure Fluctuation: ±1% (Water-free, oil-free, filtered, and pressure-stabilized clean air)

5.3. Equipment Specifications:

Weight: Approx. 0.12 tons

Dimensions: Approx. L(0.52m) x W(0.6m) x H(0.85m)

Color: Light gray or as specified by the customer

5.4. Environmental Requirements:

Temperature: 25±5℃

Relative Humidity: 30%~75% RCH, ensure the site air is dry and well-ventilated, free from acid and alkali corrosion

Earthing: Protective grounding.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com