- Battery Manufacturing Equipment

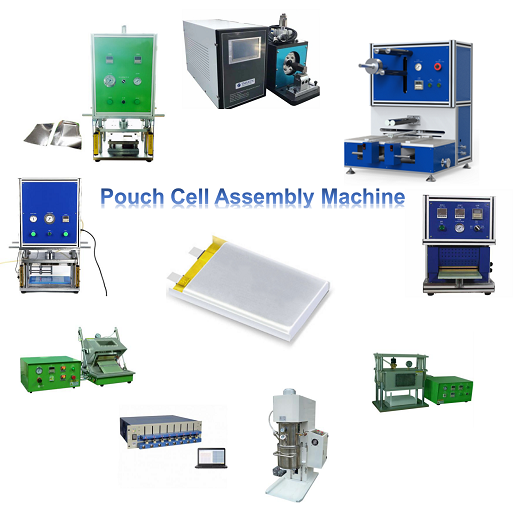

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

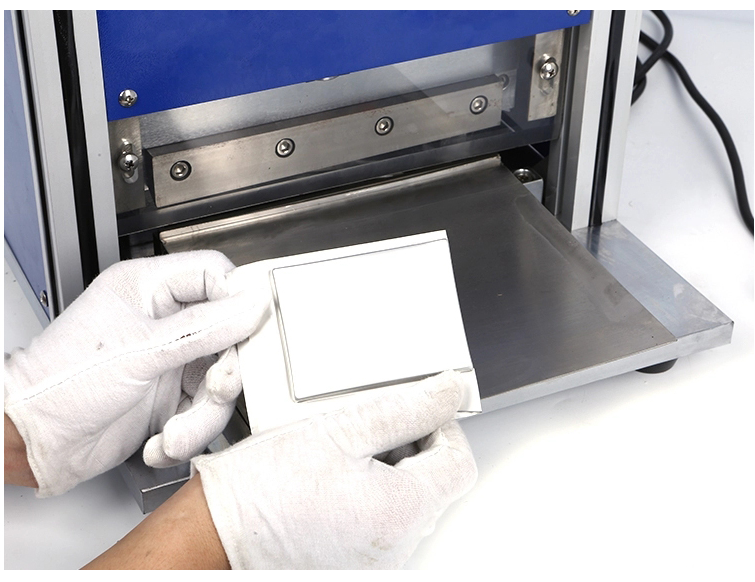

Lab Pouch Cell Case Edge Trimming Machine

Model Number:

TMAX-QP200Type:

Trimming MachineDimension(L*W*H):

L320x W180x H340mmNet Weight:

35kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Lab Pouch Cell Case Edge Trimming Machine

TMAX-QP200 is widely used in the final steps of pouch cell battery pilot-scale production line to ensure a smooth, neat and tidy casing edge.

|

Max. Power Consumption |

20W |

|

Working Voltage |

110 - 240VAC, single phase |

|

Compress Air Pressure Requirement |

0.5 - 0.7 MPa (Each stroke will consume 0.09L air ) |

|

Size Info (Trimming Width/Length) |

Trimming Width: 2~8mm adjustable Max. Trimming Length: 200mm High-quality tooling steel blades. |

|

Stroke Frequency |

~10 seconds per trial |

|

How to use this Tool Suite |

When the pouch cell is fabricated, an uneven edging excess is expected. In order to make a neat and tidy cell with smooth edge just like the commercial pouch batteries, please follow the steps in below: |

|

Net Weight |

35kg |

|

Product Dimensions |

L320x W180x H340mm |

|

Compliance |

CE Certificate |

|

Warranty |

One Year limited warranty with lifetime support |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com