- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

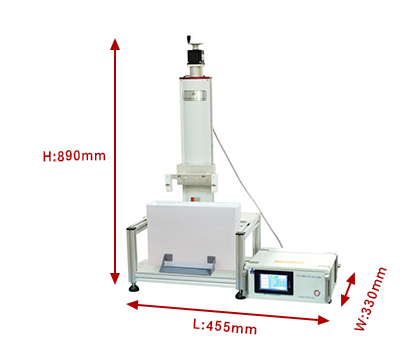

Lab Program Controlled Vertical Dip Coating Machine with Touch Control Screen

Model Number:

TMAX-PTL-MM02-200Dimension(L*W*H):

560mm(L) x 470mm(W) x 1435mm(H)Net Weight:

105kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Lab Program Controlled Vertical Dip Coating Machine with Touch Control Screen

Product introduction

PTL-MM02-200 program controlled vertical dip coating machine is a precision equipment designed for the study of liquid phase growth film, by vertically lifting samples impregnated in the liquid phase to grow film. Large samples can be coated, sample size up to 310mm×260mm, thickness of 1mm-5mm, by customizing different sample clips can also be fixed multiple samples at a time. The lifting speed of the sample, the impregnation time of the sample in the liquid film material, the inlet speed of the sample, the number of cycles of the sample film coating, and the drying time of the sample can be controlled by the control system. PTL-MM02-200 program controlled vertical dip coating machine adopts high precision speed control system and touch screen parameter input to realize automatic control of the whole process of lifting and drawing film. The machine is small in size, simple and convenient in operation, and is an ideal equipment for the coating of large samples in laboratories and small production workshops at room temperature.

Main features:

a.Touch control screen is used to set lifting speed, descending speed and residence time according to actual needs.

b.It can set the lifting speed, impregnation time, inlet speed, number of cycles and drying time.

c.Adopt high precision stepper motor.

d.It has passed the CE certification.

Technical parameter

|

Product name |

PTL-MM02-200 program controlled vertical dip coating machine |

|

|

Product model |

PTL-MM02-200 |

|

|

Installation condition |

The equipment is required to be used at an altitude of less than 1000m, at a temperature of 25℃±15℃, and at a humidity of 55%Rh±10%Rh. 1. Water: No need 2. Electricity: AC220V 50Hz, must have good grounding 3. Gas: No need 4. Workbench: size 800mm×600mm×700mm, bearing capacity of more than 200kg 5. Ventilation device: no need |

|

|

Main parameter |

1. Power supply: 220V(50Hz) |

|

|

2. Running (up and down) speed: 1mm/min-200mm/min |

||

|

3. Stroke: 270mm |

||

|

4. Sample size :(L)310(mm)×(W)260 (mm)×(T) 1~5 (mm) |

||

|

5. Lifting load: ≤5.5kg |

||

|

6. The two-phase hybrid stepper motor is subdivided by the driver stepping Angle |

||

|

7. Dipping, drying time setting: 1-999s |

||

|

8. Can be lifted: 1-20 times |

||

|

9. Product specifications: Dimensions:455mm(L)x330mm(W)x 890mm(H) |

|

|

Standard fittings

|

No. |

Name |

Qty |

|

1 |

Control box |

1 PC |

|

2 |

Immersion tank |

1 PC |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com