- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Lithium Battery Electrode Extrusion Slot Die Coating Machine

Model Number:

TMAX-3327DCompliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Lithium Battery Electrode Extrusion Slot Die Coating Machine

1. Equipment functions and parameters

|

1. Base material parameter |

||

|

|

Anode substrate |

Cathode substrate |

|

Name |

Copper foil |

aluminum foil |

|

Thickness |

(8-30) μm |

(10-30) μm |

|

Substrate width |

(200-320) mm |

(200-320) mm |

|

2. Coating parameter |

||

|

Material name |

Anode slurry |

Cathode slurry |

|

Graphite, mesophase carbon, hard carbon, etc. |

Lithium cobalt oxide, lithium nickel cobalt manganese, lithium manganate, lithium iron phosphate, etc. |

|

|

Coating dry thickness |

(50-150) μm (without foil, single-sided dry material) |

(50-150) μm (without foil, single-sided dry material) |

|

Wet coating thickness |

100μm~300μm |

100μm~300μm |

|

Solid content |

(40-70) ±5% |

(30-80) ±5% |

|

Specific gravity |

(1.0-1.4) g/cm3 |

(1.0-2.5) g/cm3 |

|

Viscosity |

(2500-8000) CPS |

(1000-10000) CPS |

|

Temperature |

According to the process control RT~140℃, using electric heating |

|

|

Solvent |

NMP oil system/water system |

NMP oil system/water system |

|

3. Machine basic parameter |

||

|

Coating roll width |

400mm |

|

|

Effective coating width |

300mm and below; |

|

|

Coating method |

Continuous extrusion coating (including strip coating)/intermittent extrusion coating |

|

|

Dressing coating speed |

1~5m/min (related to oven temperature, slurry state and coating process settings); |

|

|

power supply |

380 V x 50 Hz, three-phase (control power supply 220 V x 50 Hz, single-phase) |

|

|

Total power |

Max 50KW |

|

|

Gas source |

0.6 MPa |

|

|

The total length of the machine: not more than 10 meters |

||

2. Introduction to the structure of each part:

2.1. Integral unwinding, head mechanism:

|

No. |

Item name |

Technical parameter |

|

1 |

Roller installation structure |

Rack installation |

|

2 |

Roller surface treatment |

Surface oxidation of metal aluminum roller |

|

3 |

Tension control system |

Closed loop automatic control constant tension, tension range 0~50N |

|

4 |

Correction method |

Automatic EPC control, stroke 80mm |

|

5 |

Coiling method |

The material roll is fixed with a 3-inch air shaft; |

|

Unwinding uniaxial support |

||

|

6 |

Direction of substrate movement |

Forward and reverse |

|

7 |

Base material running speed |

5m/min |

|

8 |

Maximum unwinding diameter |

Ф300mm |

|

9 |

Maximum bearing capacity of inflatable shaft |

100Kg |

|

10 |

Number of unwinding inflatable shafts |

1 piece |

|

11 |

Main drive motor |

Servo motor + precision planetary reducer |

|

12 |

Adjust the knife |

Servo + Keyence grating ruler |

|

13 |

Roller surface treatment |

The surface of the metal aluminum roller is oxidized, and the circle runout ≤30um |

|

14 |

Coating method |

Continuous extrusion coating / gap extrusion coating |

|

15 |

Die parameters |

l Die width: at 20 degrees Celsius, the die length is 400mm0.5mm; l Mold body material: 15-5ph stainless steel; l Polishing accuracy of runner surface: 4-6Ra (micro inches); l Feeding position: back feeding; l Products and applications: 3-300 micron positive/negative slurry, lithium ion battery applications |

|

16 |

Coating roll (steel roll) |

l Special steel pipe, diameter Ø120mm, hard chrome plating l Circle runout accuracy within 2um l Linear speed range 2~5m/Min l There is no abnormal noise, abnormal vibration and heat generation in all parts when driving |

|

17 |

Roll specifications |

Diameter Ø80mm, surface covered with imported EPDM glue |

|

18 |

Extrusion die head movement |

l Base drive: button operation (large range movement using air cylinder) l Gap fine adjustment: button operation (use servo motor action) l Gap detection: grating ruler (accuracy 1um) |

|

19 |

Single head position |

Installation and operation before drying tunnel |

2.2 Pumping system

|

No. |

Name |

Description |

|

1 |

Screw pump |

Japanese Heishin screw pump |

|

2 |

Transfer tank |

30 liters in volume, pressure control, liquid level detection, slow stirring, |

|

3 |

Material reflow coating controller |

Material reflow coating controller |

|

4 |

filter |

The mesh number is customized according to customer needs |

|

5 |

Iron remover |

Above 8000 Gauss |

|

6 |

Pressure balance buffer |

Ensure the pipeline pressure is balanced |

|

7 |

Pipes and accessories |

Stainless steel quick couplings and stainless steel pipe fittings |

|

8 |

Pressure monitoring system |

Pressure monitoring system |

2.3 Drying oven

|

No. |

Item name |

technical parameter |

|

1 |

Oven structure |

Double heating, arranged up and down |

|

2 |

Oven length |

6 meters (2 meters/section*3) |

|

3 |

Material |

SUS304 stainless steel, inner tank 1.0mm, outer tank 1.2mm |

|

4 |

Oven guide roller transmission mode |

Passive roller drive |

|

5 |

temperature control |

Divided into normal working temperature control, over-temperature monitoring and alarm protection control, cut off the heating power when over-temperature; each section is completely independent control |

|

6 |

Heating method |

Electric heating, hot air circulation structure |

|

7 |

Heating power of single section oven |

12KW/2m |

|

8 |

Temperature in the drying tunnel |

Max.150℃, temperature difference in single oven ≤5℃ |

|

9 |

Surface temperature of cabinet during operation |

≤45℃ |

|

10 |

Blowing method |

The upper and lower air blows, and the upper and lower air volumes are separately controlled by valves; the upper and lower air chambers share the heating body |

|

11 |

Each section of exhaust air volume control |

Circulating fan air volume 3000m³/h (single section) Exhaust air volume 4000m³/h |

|

12 |

Nozzle structure |

The blowing direction is 30 degrees to the level, and the nozzle slot is slotted by a special mold |

|

13 |

Heating control |

solid state relay |

|

14 |

Fan material |

SUS304 stainless steel |

|

15 |

Solvent recovery system |

Optional |

|

16 |

NMP solvent concentration alarm |

Optional(add $4390) |

2.4 Winding mechanism: the same function as unwinding

|

No. |

Item name |

technical parameter |

|

1 |

Tension |

1 set is installed in front of the traction roller, which can automatically control constant tension, the tension range is 0~50N, and servo winding. |

|

2 |

Installation structure |

Square through frame welding bottom frame, single-sided vertical plate |

|

3 |

Number of winding shafts |

1 piece |

|

4 |

Winding diameter |

Ф300mm |

|

5 |

Winding correction |

Automatic EPC control, stroke 80mm |

2.5 Control system

|

No. |

Item name |

technical parameter |

|

1 |

Main control system |

Touch screen, PLC, module, servo system |

|

2 |

Operation mode |

Manual, automatic, emergency stop; |

|

3 |

Coating, intermittent length setting range |

Coating length 20.0~3200.0mm Intermittent length 5.0~3200.0mm |

|

4 |

Alarm situation |

When the device fails, the touch screen will display the corresponding correction screen |

|

5 |

Counting function |

Production quantity/length |

3. Equipment accuracy:

3.1. Hardware accuracy

|

1 |

Coating roller (steel roller) |

Circle runout≤1.5um, Ra0.4 Straightness≤1.5um |

|

2 |

glue roll |

Circle runout≤10um, straightness≤10um |

|

3 |

Correction deviation |

±0.1mm |

|

4 |

Temperature control accuracy |

±2℃ |

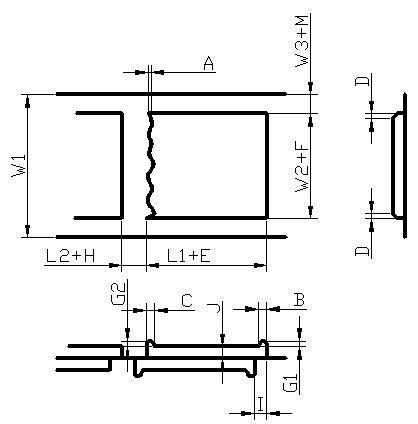

3.2. Coating accuracy

|

|

A (tailing) |

≤1mm (Related to slurry viscosity and adhesive properties) |

|

B (abnormal area of the head) |

10mm |

|

|

C (abnormal area of tail) |

6mm |

|

|

D (edge effect area) |

≤3mm |

|

|

E (length error) |

±0.5mm |

|

|

F (width error) |

±0.5mm |

|

|

M (width error) |

±0.5mm |

|

|

G1 (head thickness) |

+5um ~ -10 |

|

|

G2 (Tail thickness) |

+5um ~ -10 |

|

|

H (blank error) |

±0.5mm |

|

|

I (positive and negative bit error) |

±0.5mm |

|

|

L1 (coating film length) |

20.0~3200.0mm |

|

|

Length range |

L2 (intermittent length) |

5.0~3200.0mm |

|

L1/L2(coating+discontinuous length) |

L1 +L2 ≥90mm |

4. Machine main configuration

|

No. |

Item name |

Brand |

|

1 |

air switch |

CHNT/DELIXI |

|

2 |

PLC |

OMRON |

|

3 |

touch screen |

WEINVIEW |

|

4 |

modular |

OMRON |

|

5 |

Intermediate relay |

Schneider |

|

6 |

servo motor |

Mitsubishi |

|

7 |

Planetary reducer |

Fenghua |

|

8 |

Circuit breaker |

Schneider |

|

9 |

AC contactor |

Schneider |

|

10 |

Solid state relay |

FOTEK |

|

11 |

thermostat |

OMRON |

|

12 |

Automatic deviation correction |

Ultrasonic |

|

13 |

Optical fiber electric eye |

KEYENCE |

|

14 |

Push the cylinder |

AirTAC/CHELIC |

|

15 |

Coating roller |

Hard chromium electroplating |

|

16 |

Guide roller |

Anodic treatment of aluminum alloy surface |

|

17 |

Frequency converter |

Delta |

|

18 |

Coating die |

Imported from Japan |

|

19 |

Screw pump |

Heishin |

5. installation environment requirements

1) The ambient temperature of the machine head is 20~30℃, and the rest is 10~40℃;

2) The relative humidity of the machine head, positive RH ≤35%, negative RH ≤48%, and the rest ≤48%;

6. Supporting facilities

1) Power supply: 3PH 380V, 50HZ, voltage fluctuation range: +8%~-8%; the total starting power of the power supply is ≤50KW;

2) Compressed air: After drying, filtering and stabilizing: the outlet pressure is greater than 5.0kg/cm2;

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com